Guided wave radar level transmitters are level measuring instruments based on the time travel principle. The probe emits high-frequency pulses that propagate along the cable or rod probe. When the pulse encounters the surface of the material, it is reflected back and is received by the receiver in the instrument, which converts the distance signal into a level signal.

The transmission of microwave signals is not affected by the atmosphere, so it can meet the requirements of harsh environments such as volatile gases, high temperatures, high pressures, steam, vacuum and high dust during the process. This product is suitable for harsh environments such as high temperature, high pressure, vacuum, steam, high dust and volatile gases. Can continuously measure different material levels.

Features

guided wave radar level transmitter | GWR product list

Featured Guided Wave Radar Level Transmitters Models and Technical Parameters

701 Guided Wave Radar Level Transmitter – Liquid, Solid Powder

- Applicable media: liquid, solid powder;

- Application: liquid and solid powder measurement, complex process conditions;

- Explosion-proof certification: Exia IIC T6 Ga/ Exd IIC T6 Gb;

- Measuring range: 30m;

- Frequency: 500MHz-1.8GHz;

- Antenna: single cable or single pole antenna;

- Measurement accuracy: ±10mm;

- Process temperature: -40~130℃ (standard type)/-40~250℃ (high temperature type);

- Process pressure: (-0.1~4) MPa;

- Signal output: (4~20)mA/HART;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Shell: aluminum single cavity/aluminum double cavity/plastic/stainless steel single cavity;

- Process connection: thread/flange (optional);

702 Guided Wave Radar Level Transmitter for Liquid, Highly Corrosive Liquid

- Applicable medium: liquid, especially highly corrosive liquid;

- Application: Measurement of acids, alkalis or other corrosive media;

- Explosion-proof certification: Exia IIC T6 Ga/ Exd IIC T6 Gb;

- Measuring range: 20m;

- Frequency: 500MHz-1.8GHz;

- Antenna: fully PTFE sealed cable or rod antenna;

- Measurement accuracy: ±10mm;

- Process temperature: -40~130℃ (standard type) /-40~200℃ (high temperature type);

- Process pressure: (-0.1~0.3)MPa;

- Signal output: (4~20)mA/HART;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Shell: aluminum single cavity/aluminum double cavity/plastic/stainless steel single cavity;

- Process connection: thread/flange (optional);

703 Guided Wave Radar Level Transmitter for solid powder

- Applicable medium: solid powder;

- Application: measurement of cement silo powder; measurement of fly ash powder;

- Explosion-proof certification: Exia IIC T6 Ga/ Exd IIC T6 Gb;

- Measuring range: 30m;

- Frequency: 500MHz-1.8GHz;

- Antenna: dual-cable antenna;

- Measurement accuracy: ±10mm;

- Process temperature: (-40~130)℃;

- Process pressure: (-0.1~4) MPa;

- Signal output: (4~20)mA/HART;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Shell: aluminum single cavity/aluminum double cavity/plastic/stainless steel single cavity;

- Process connection: thread/flange (optional);

704 Guided Wave Radar Level Transmitter for Liquids, Low Dielectric Constant Liquids

- Applicable medium: liquid, especially liquid with low dielectric constant;

- Application: Measurement of liquids such as ion-free water and deoxygenated water;

- Explosion-proof certification: Exia IIC T6 Ga/ Exd IIC T6 Gb;

- Measuring range: 6m;

- Frequency: 500MHz-1.8GHz;

- Antenna: coaxial tube antenna;

- Measurement accuracy: ±5mm;

- Process temperature: -40~130℃ (standard type)/-40~250℃ (high temperature type);

- Process pressure: (-0.1~4) MPa;

- Signal output: (4~20)mA/HART;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Shell: aluminum single cavity/aluminum double cavity/plastic/stainless steel single cavity;

- Process connection: thread/flange (optional);

705 Guided Wave Radar Level Transmitter for liquid, high temperature and high pressure liquid

- Applicable medium: liquid, especially liquid in high temperature and high pressure environment;

- Application: Sealed tanks, measurement of liquids with high pressure;

- Explosion-proof certification: Exia IIC T6 Ga/ Exd IIC T6 Gb;

- Measuring range: 15m;

- Frequency: 500MHz-1.8GHz;

- Antenna: single pole or single cable type;

- Measurement accuracy: ±10mm;

- Process temperature: (-200~400)℃;

- Process pressure: (-0.1~40) MPa;

- Signal output: (4~20)mA/HART;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Shell: aluminum single cavity/aluminum double cavity/plastic/stainless steel single cavity;

- Process connection: thread/flange (optional);

guided wave radar level transmitter working principle

Guided wave radar is a measuring instrument based on the time travel principle. Radar waves run at the speed of light, and the running time can be converted into level signals through electronic components.

The probe emits a high-frequency pulse and propagates along the cable or rod probe. When the pulse encounters the material surface, it is reflected back and is received by the receiver in the instrument, and the distance signal is converted into a level signal.

The reflected pulse signal is transmitted along the cable or rod probe to the electronic circuit part of the instrument. The microprocessor processes the signal and identifies the echo generated by the microwave pulse on the material surface.

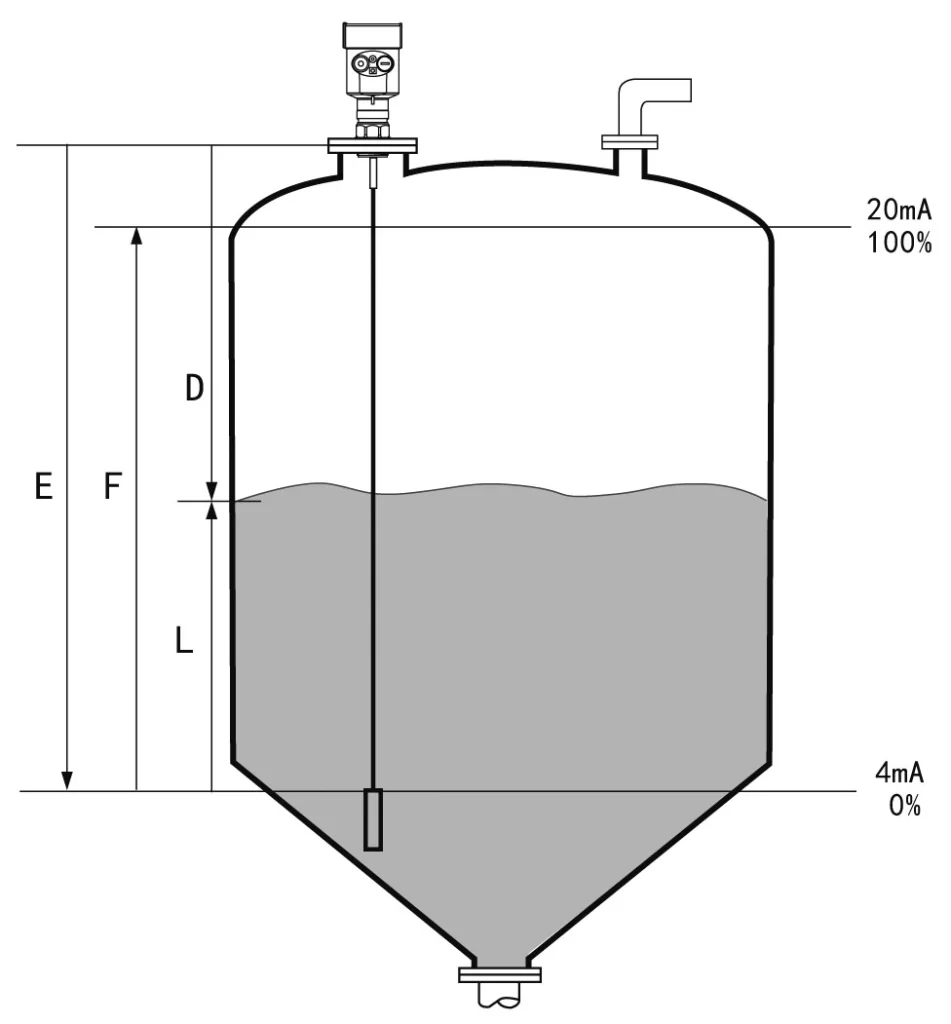

Correct echo signal identification is done by the pulse software. The distance D from the material surface is proportional to the pulse time T:

D=C×T/2

Where C is the speed of light. Since the distance E of the empty tank is known, the level L is: L=E-D

Set by inputting the empty tank height E (= zero point), the full tank height F (= full scale) and some application parameters. The application parameters will automatically adapt the instrument to the measurement environment, corresponding to 4-20mA output.

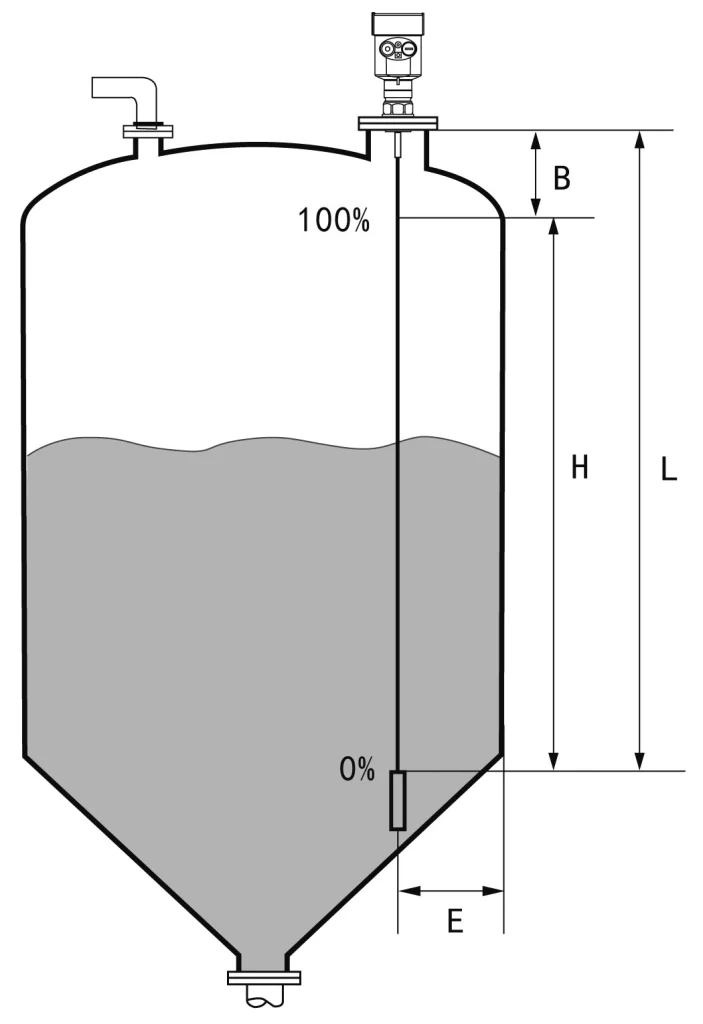

Measuring range:

illustrate:

H—-Measurement range

L—-empty tank distance

B—-Top blind area

E—-Minimum distance from probe to tank wall

The top blind zone refers to the minimum distance between the highest surface of the material and the measurement reference point.

The bottom dead zone is a distance near the very bottom of a cable that cannot be accurately measured.

The effective measurement distance is between the top blind zone and the bottom blind zone.

Notice:

Only materials are in the top blind zone and bottom blind zone

can ensure the reliability of the content level in the tank.

Measurement.

guided wave radar level transmitter dielectric constant

The guided wave radar level transmitter on the market can measure almost any liquid with a dielectric constant greater than 1.6.

But if the liquid medium is less than 1.6, what should we do if we need to use a guided wave radar radar level meter for liquid level measurement?

At present, the most effective method is to install a waveguide.

However, this method has certain limitations. That is, the dielectric constant of the liquid medium must be greater than 1.3, the viscosity should be less than or equal to 500cst, and it is not prone to adhesion.

guided wave radar level transmitter applications

The guided wave radar level transmitter has a wide range of applications due to its high accuracy, fast response speed, and good reliability. Common liquid level measurement application scenarios are as follows:

guided wave radar level transmitter calibration

There are 3 calibration methods for guided wave radar level transmitter:

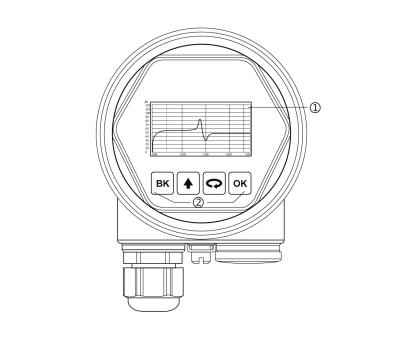

- Display/debug module (View Point)

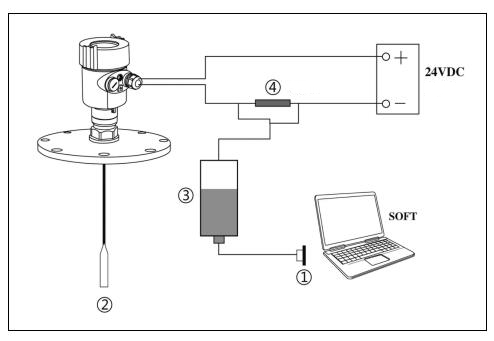

- PC debugging software

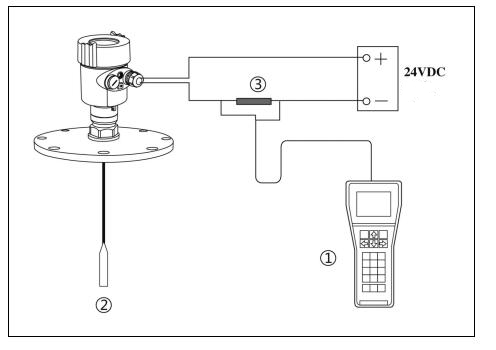

- HART handheld programmer

For more about guided wave radar level transmitter installation and troubleshooting, please continue reading our blog.

- Guided Wave Radar Level Transmitter Installation Guide and Troubleshooting

- Difference Between Radar and Guided Wave Radar Level Transmitter

guided wave radar level transmitter selection guide

When we select a guided wave radar level transmitter, we mainly need to consider the following parameters:

| Tank/Container Information |

| Tank type: |

| □ Storage tank □ Reaction tank □ Separation tank □ Marine storage tank |

| Storage tank structure: □ Tank material: □ Pressure: |

| Tank size: □ Tank height: m □Diameter: m |

| Tank roof: □ Vault type □ Flat top type □ Open type □ Conical top type |

| Tank bottom: □ cone bottom □ flat bottom □ slope bottom □ curved bottom |

| Installation: □ Top installation □ Side installation |

| □ Bypass pipe installation □ Still pipe installation |

| Installing nozzles on the tank roof (important information) |

| Nozzle height: mm Nozzle diameter: mm |

| Measuring medium |

| Medium name: □ Liquid □ Solid □ Mixed medium |

| Medium temperature: ℃ Dielectric constant: |

| Hanging material: □ Yes □ No |

| Stirring: □ Yes □ No |

| Process connection |

| Thread: (□ G1½″ □ 1½″ NPT) Flange (DN= ) Flange (ANSI= ) |

| Power supply: |

| □ 24V DC two-wire system □ 24V DC four-wire system □ 220V AC four-wire system |

| Output: □ 4-20mA □ HART |

| Display: □ With meter display programming □ Without meter display programming |

More Featured Level Measurement

The guided wave radar level transmitter has the advantages of high precision, fast response speed, and good reliability. It is widely used in liquid level monitoring in various fields such as petrochemical, food, and sewage treatment.

The guided wave radar level transmitters supplied by us at Sino-Inst are widely exported to various countries, with Best price! The measurement effect is stable. Of course, we also have other types of level transmitters, including radar level meters, ultrasonic level meters, hydrostatic level meters, float level controllers, etc.

If you need to purchase guided wave radar level transmitters, or have related customization needs, please feel free to contact us!

Guided Wave Radar Level Transmitters | GWR Product List

Guided wave radar level transmitters are level measuring instruments based on the time travel principle. The probe emits high-frequency pulses that propagate along the cable or rod probe. When the pulse encounters the surface of the material, it is reflected back and is received by the receiver in the instrument, which converts the distance signal into a level signal.

Product SKU: Guided Wave Radar Level Transmitters | GWR Product List

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 599

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)