Flowmeters are divided into explosion-proof and non-explosion-proof types according to their electrical structure. Explosion Proof Flow Meters are mainly used in flammable, explosive, toxic or other hazardous environments. In these situations, the equipment may be exposed to flammable gases, steam, dust, etc., so it needs to be explosion-proof to ensure safe and reliable operation.

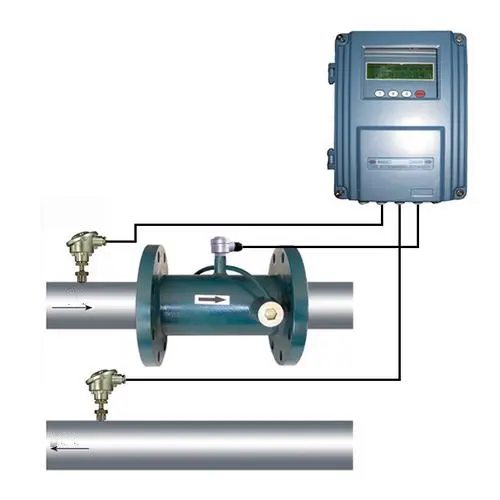

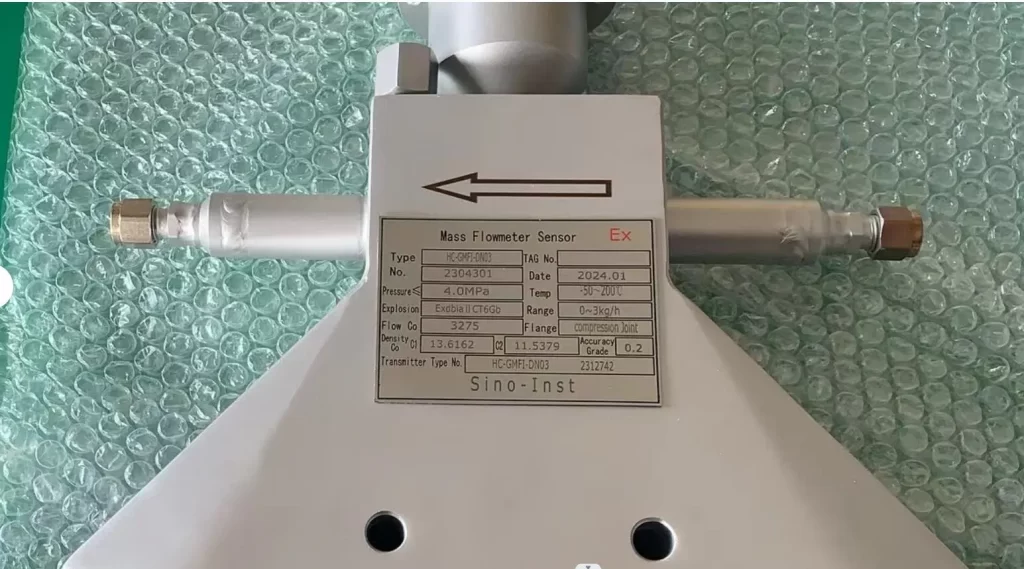

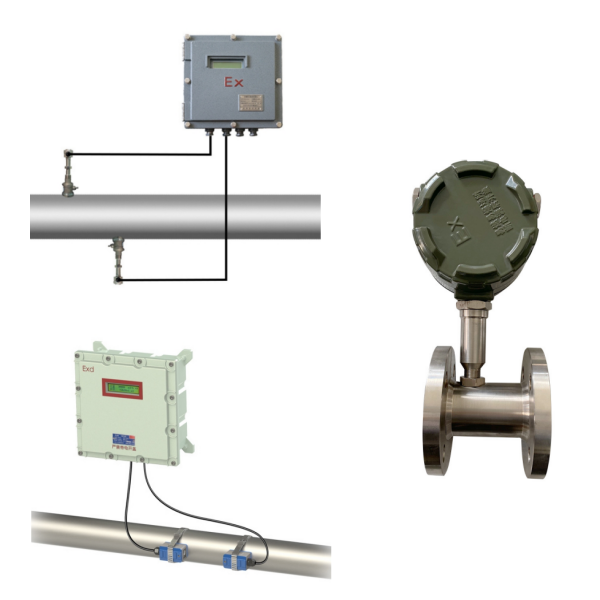

We at Sino-Inst supply various types of Explosion Proof Flow Meters. Including: explosion proof mass flow meter, explosion proof air flow sensor, explosion-proof turbine flow meter, explosion-proof ultrasonic flow meter, explosion-proof electromagnetic flow meter, etc.

Featured Explosion Proof Flow Meters

When require the use of explosion proof flow meters?

Petrochemical industry: During the extraction, processing, transportation and storage of oil and natural gas, flammable and explosive gases and liquids may exist. For example, Sinopec’s petroleum products transportation.

Chemical industry: In the chemical production process, flammable, explosive or toxic chemicals may be involved, such as organic solvents, acids and bases, etc.

Oil and gas storage facilities: Oil and gas storage tanks, pipelines and other facilities may have the risk of gas leakage.

Oil transportation: During the transportation of oil products, involving the loading, unloading, and transportation of oil products, there may be risks of gas leakage or contact with fire sources.

Coal mines and coal chemical industry: During the coal mining process, flammable and explosive gases such as gas (methane) may exist; during the coal chemical industry, flammable and explosive chemicals may also be produced.

Dust environment: Some industries (such as grain processing, wood processing, etc.) may produce large amounts of dust, which can also be explosive under certain conditions.

Pharmaceutical industry: In the pharmaceutical production process, flammable, explosive or toxic chemicals, such as organic solvents, may be involved.

In these situations, it is very important to choose a flowmeter with explosion-proof function. Explosion-proof flow meters usually use special explosion-proof designs and materials to ensure safe and reliable operation in flammable, explosive or toxic environments. When choosing an explosion-proof flowmeter, be sure to pay attention to the explosion-proof grade and certification of the equipment to ensure that it meets relevant safety standards and regulatory requirements.

Next, let’s take a look at the introduction of the explosion-proof grade of the flow meter.

Explosion-proof grade of flow meters

The explosion-proof level of an explosion-proof flowmeter is usually determined based on the environmental conditions and risks of its use in explosion-risk areas. Explosion-proof levels are divided into the following levels:

There are 8 types of explosion-proof, namely explosion-proof type “d”, increased safety type “e”, intrinsic safety type “I”, positive pressure type “p”, oil-filled type “o”, sand-filled type “q”, non-sparking Type “n” and special type “S”.

Among electric instruments, explosion-proof type “d” and intrinsically safe type “i” are mainly used. For example, the explosion-proof levels of our Sino-Inst vortex gas flowmeter include explosion-proof: ExdIICT2~T6Gb, ExdIIBT2~T6Gb, and intrinsic safety: ExiaⅡCT2~ T6Gb, ExialIBT2~T6Gb are optional. The mass flow meter is available in Ex d [ia]ⅡC T6 Gb. Oval gear flowmeter is ExdⅡBT4 grade, etc.

What is explosion proof?

Explosion-proof, also known as pressure-resistant explosion-proof, encloses components that can ignite explosive mixtures in a shell. The shell can withstand the explosion pressure of the explosive mixture inside and prevent the explosive mixture from propagating to the outside of the shell, that is, an explosion may occur inside the flameproof instrument. Therefore, it is forbidden to open the cover of explosion-proof meters at will before completely cutting off the power supply, otherwise it may cause an explosion.

What is intrinsically safe?

Intrinsically safe instruments limit the electrical parameters so that the sparks and energy produced under normal or specified fault conditions cannot ignite the surrounding explosive gas mixture.

Common explosion-proof grades

Explosion-proof grade Ex ia: The highest level of explosion-proof grade, suitable for flammable gas environments, such as ethane, propane, etc. This class of flowmeter can be installed directly in hazardous areas with very high safety and reliability.

Explosion-proof grade Ex d: Suitable for flammable gas, vapor and liquid environments, such as natural gas, gasoline, oil, etc. Flowmeters of this class are resistant to explosion hazards and can withstand higher pressures and temperatures. This is the commonly used explosion-proof level for VTON explosion-proof flowmeters in the United States.

Explosion-proof grade Ex n: suitable for flammable gas environments, such as propane, methane, etc. This level of flow meter has high explosion-proof performance, but compared with the Ex d level flow meter, the safety and reliability are lower.

Explosion-proof grade Ex e: suitable for flammable gas, vapor and liquid environments, such as ethane, natural gas, gasoline, oil, etc. This level of flow meter has high explosion-proof performance, but compared with the Ex d level flow meter, the safety and reliability are lower.

Explosion-proof grade Ex p: suitable for flammable gas, vapor and liquid environments, such as ethane, natural gas, gasoline, oil, etc. This level of flow meter has high explosion-proof performance, but compared with the Ex d level flow meter, the safety and reliability are lower.

More Featured Flow Measurement Solutions

- What Is Temperature Compensation and Pressure Compensation for Flow Meters?

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

- Fluid Flow Sensor | Types and Product List

- What Is Variable Area Flow Meter?

- Flowmeter Selection Guide | Find the Best One for Your Application

- 11 Flow Meter Types and Their Advantages and Disadvantages

Before purchasing a flowmeter, you should fully understand the protection level and explosion-proof standards of the flowmeter to ensure that it is suitable for the specific working environment. Explosion Proof Flow Meters are important requirements for safe use in flammable and explosive environments.

Users should choose a flowmeter that complies with relevant explosion-proof standards and ensure that it meets the corresponding explosion-proof level and regional requirements. This usually involves the selection and configuration of explosion-proof enclosures, anti-static measures and explosion-proof electrical components. In order to minimize potential safety risks and protect the safety of equipment and operators.

Most of our Sino-Inst flowmeters comply with explosion-proof standards and are suitable for use in Explosive or Hazardous Areas. If you need to purchase Explosion Proof Flow Meters, or have related questions, please feel free to contact us.

-1.jpg)