Rotameter Flow Meter is a process instrument used to measure the volume flow of pipeline gas or liquid. It adopts the variable area measurement principle. It has the characteristics of small size, large detection range, and easy use. It can be used to measure the flow of liquids and gases. It is especially suitable for medium flow measurement with a low flow rate and small flow rate.

The Rotameter Flow Meters produced by our Sino-Inst support the customization of DN15~DN200. Can be configured with explosion-proof, intelligent transmitter, output 4-20mA signal, and HART protocol. Two alarm outputs can be configured.

Features

Rotameter Flow Meters Technical Parameters

| Measuring range | Water (20℃): 1-200000 L/h Air (20℃, 0.1013MPa): 0.03~4000m³/h |

| Turndown | Standard type 10:1, special type 20:1 |

| Accuracy | Gas 2.5%FS; Liquid 1.5%F.S |

| Pressure Level | Standard type: DN15-N50 4.0MPa; Special type: DN15-N50 25 MPa; The pressure rating of the jacket is 1.6MPa. For special models, please consult and confirm before selecting and ordering. |

| pressure loss | 2kpa-20kpa |

| Medium temperature | Standard type: -40℃~100℃; PTFE: 0℃~120℃; High temperature type: 100℃~450℃; |

| Medium viscosity | DN15: η<5mPa.s(F15.1-F15.3) η<30mPa.s (F15.4-F15.8) DN25: η<30mPa.s DN50-DN150: η<30mPa.s |

| ambient temperature | Remote transmission type: 40℃~185℃ (the liquid crystal will not be damaged), the liquid crystal normally works at -30℃~80℃; local pointer type: -40℃~100℃ |

| Connection Type | Connection method: flange connection standard HG20592-2010, DIN 2501 standard flange; or produced according to customer requirements; Threaded connection: produced according to diameter or customer requirements; Sanitary clamp connection: produced according to diameter or customer requirements; |

| Cable interface | The flameproof type is 1/2NPT internal thread; other M20*1.5 internal thread; |

| Power supply | Standard type: 24VDC two-wire system 4-20mA (12VDC-32VDC); Alarm type: 24VDC three-wire system 4-20mA (18VDC-28VDC); AC type: 85-265VAC50Hz; Battery type: 3.6V, 7.5AH battery, used continuously for three years; |

| Load characteristics | Two-wire system: RLmax=50*(-12)Ω=600Ω@24V Alarm type: the maximum load resistance is 200Ω AC type: the maximum load resistance is 200Ω |

| Alarm Output | Upper or lower limit instantaneous flow alarm; Switch quantity alarm; Relay output; |

| LCD | Instantaneous flow rate display value range: 0-50000 (with decimal point) Accumulated flow display value range: 0-99999999 (with decimal point) automatic reset |

| Protection level | IP65 |

Flow Range

| Liquid(L/h) | Gas | ||

| Nominal Diameter | Material RO.R1,R2,TI,RL | Materlal PTFE | Nm³/h (under standard state) |

| DN15 | 1~10 | 1.6~16 | 0.03~0.3 |

| 6~16 | 2.5~25 | 0.05~0.5 | |

| 2.5~25 | 4.0~40 | 0.07~0.7 | |

| 4.0~40 | 6.0~60 | 0.11~1.1 | |

| 6.3~63 | 10~100 | 0.18~1.8 | |

| 10~100 | 16~160 | 0.28~2.8 | |

| 16~160 | 25~250 | 0.48~4.8 | |

| 25~250 | 40~400 | 0.7~7 | |

| 40~400 | 60~600 | 1.0~10 | |

| 63~630 | 1.6~16 | ||

| 100~1000 | |||

| DN20 | 63~630 | 40~400 | 1,6~16 |

| 80~800 | 63~630 | 2.4~24 | |

| 100~1000 | 80~800 | 3.6~36 | |

| DN25 | 63~630 | 40~400 | 1.6~16 |

| 100~1000 | 63~630 | 3~30 | |

| 160~1600 | 100~1000 | 4.5~45 | |

| 250~2500 | 160~1600 | 7~70 | |

| 400~4000 | 250~2500 | 11~110 | |

| DN32 | 500~5000 | 400~4000 | 14~140 |

| 800~8000 | 500~5000 | 23~230 | |

| 1000~10000 | 800~8000 | 35~350 | |

| 1500~15000 | 1000~10000 | ||

| DN40 | 630~6300 | 400~4000 | 18~180 |

| 1000~10000 | 630~6300 | 25~250 | |

| 1200~12000 | 1000~10000 | 40~400 | |

| 1600~16000 | 1200~12000 | ||

| DN50 | 630~6300 | 400~4000 | 18~180 |

| 1000~10000 | 630~6300 | 25~250 | |

| 1600~16000 | 1000~10000 | 40~400 | |

| 2000~20000 | 1500~15000 | ||

| DN65 | 1600~16000 | 1000~10000 | 40~400 |

| 2000~20000 | 1600~16000 | 65~650 | |

| 2500~25000 | 2000~20000 | 100~1000 | |

| 3000~30000 | 2500~25000 | ||

| DN80 | 2500~25000 | 1600~16000 | 70~700 |

| 4000~40000 | 2500~2500 | 100~1000 | |

| DN100 | 6300~630000 | 4000~40000 | 160~1600 |

| 1000~100000 | 6300~63000 | 250~2500 | |

| DN125 | 12000~120000 | 10000~100000 | 300~3000 |

| DN150 | 16000~160000 | 12000~120000 | 400~4000 |

| DN200 | 20000~200000 | It can be DN20,DN32,DN40,DN65,DN125 for special. | |

| Please contact and consultant with the manutadurer | |||

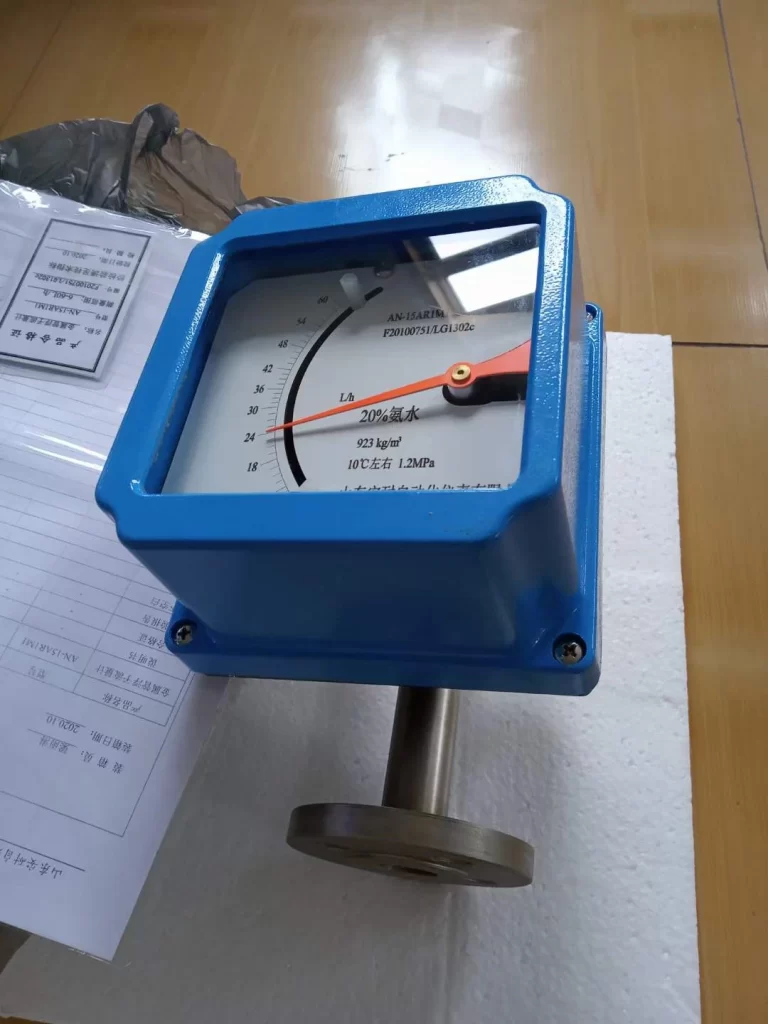

Structure of rotameter flow meter

This series of metal tube rotameter flow meters mainly consists of two parts: measuring tube and indicator.

The measuring tube includes tapered tube, guide, stopper, float and other components.

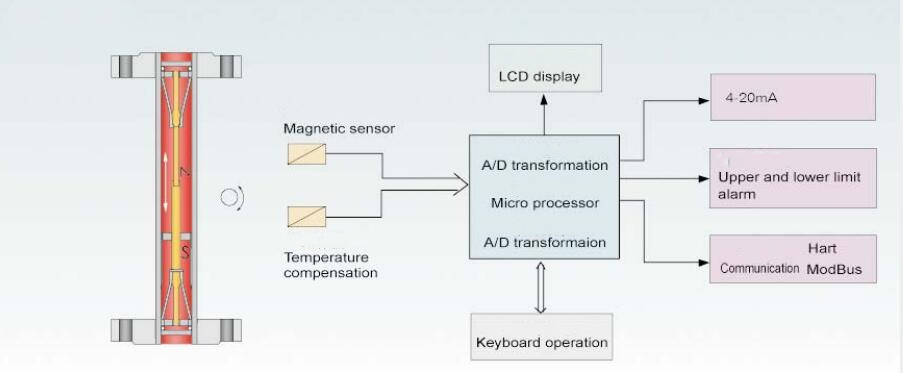

The indicator includes a magnetic follow-up system, pointers, dials, circuits and other components. Divided into local type and intelligent type.

For the local type, the following magnet in the local indicator is coupled with the magnet in the float to rotate, and at the same time the pointer is driven to indicate the flow rate at this time through the dial.

For the intelligent type, the following magnet in the intelligent indicator is coupled with the magnet in the float to cause rotation. At the same time, it drives the sensing magnet and pointer. The changes in the magnetic field are converted into electrical signals through a magnetic sensor, which is then processed by AD conversion, digital filtering, temperature compensation, microprocessor processing, D/A output, and LCD display to display the instantaneous flow and accumulated flow.

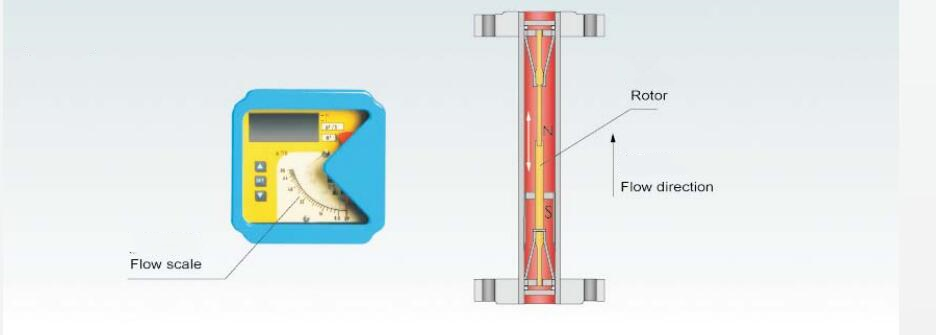

Rotameter flow meter working principle

The structure of a rotameter flow meter is a vertical tapered metal tube whose cross-sectional area gradually expands from bottom to top. There is a rotor (or float) made of metal or other materials that can rotate freely. The fluid to be measured enters from the bottom of the metal tube and flows out from the top.

When the fluid flows through the vertical tapered tube from bottom to top, the rotor is acted upon by two forces: one is the vertical upward pushing force, which is equal to the pressure difference generated by the fluid flowing through the annular cross-section between the tapered tube and the rotor.

The other is the vertical downward net gravity, which is equal to the gravity on the rotor minus the buoyancy force of the fluid on the rotor. When the flow increases so that the pressure difference is greater than the net gravity of the rotor, the rotor rises. When the pressure difference is equal to the net gravity of the rotor, the rotor is in equilibrium. That is to stay in a certain position.

A reading is engraved on the outer surface of the metal tube. According to the dwell position of the rotor, the flow rate of the measured fluid is read.

The rotameter is a variable cross-section constant pressure differential flowmeter. The pressure difference acting on the upstream and downstream of the float is a constant value. The annular cross-sectional area between the float and the tapered tube changes with the flow rate. The position of the float in the tapered tube reflects the flow rate.

Rotameter With mA Signal

Sino-Inst’s rotameters can be configured with a mechanical pointer display, suitable for measurement sites where no power supply is available. Alternatively, an intelligent display can be configured. When powered, various signal outputs are available:

- Two-wire 24VDC, 4-20mA + HART communication;

- 4-20mA + RS485 communication (Modbus RTU);

- Cumulative pulse (or instantaneous frequency), relay output;

The most commonly used 4-20mA signal provides users with simpler and more effective flow monitoring support. The flow signal can be transmitted remotely to the control room, or connected to a control valve for flow control.

More Featured Flow Meters

Rotameter vs Flow Meter

Metal Tube Rotameter: Working Principle and Applications

Rotameters: Excellent Choice for Flow Measurement in Various Gases

Mechanical Oil Flow Meter vs Digital

Variable Area Flow Meter Case: Oxygen Flow Measurement

What Is Variable Area Flow Meter?

Buyer’s Guide: 7 Checks for Selecting a Variable Area Flow Meter

Metal tube rotameter is a common flow measurement instrument that is widely used and can be used to measure media such as liquids, and gases. It is a flow meter with simple structure, high precision and strong reliability, so it can be used in various occasions.

For example, in high-temperature, high-pressure and corrosive media environments, high-temperature and corrosion-resistant materials can be used to manufacture metal tube rotor flowmeters to ensure long-term stable operation.

The metal tube rotameter produced and supplied by our Sino-Inst is simple to install and easy to operate. It does not require complicated maintenance and upkeep, reducing operation and maintenance costs and improving work efficiency. Moreover, it can also cooperate with various control systems to realize automatic control and improve the degree of automation of production.

If you need to purchase Rotameter Flow Meters-Metal Variable Area Flow Meters, or have related technical questions, please feel free to contact us.

Rotameter Flow meters ( Variable Area ) | Sino-Inst

Rotameter Flow Meter is a process instrument used to measure the volume flow of pipeline gas or liquid. It adopts the variable area measurement principle. It has the characteristics of small size, large detection range, and easy use. It can be used to measure the flow of liquids and gases. It is especially suitable for medium flow measurement with a low flow rate and small flow rate.

Product SKU: Rotameter Flow Meters-Metal Variable Area Flow Meters

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 299

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)