Pressure transducer measures the pressure of fluid, gas or liquid and converts the pressure value into an electrical signal output. Convenient for industrial automation process control. Before purchasing a pressure transmitter, measuring range, Pressure Transducer Output Signal, and connecting thread are three elements that must be clarified.

In practical applications, the selection of the pressure transducer output signal is very important, which directly affects the reliability and accuracy of the control system.

pressure sensor vs pressure transducer

When we talk about pressure measuring instruments, the terms pressure sensor and pressure transducer(pressure transmitter) are used loosely. No strict distinction is made. This is Ok. Because once we confirm the medium to be measured, range, signal output and other parameters, the manufacturer can accurately provide the products we want.

So is there no difference at all between a pressure sensor and a pressure transducer? of course not.

Pressure sensors convert non-electrical physical quantities into electrical signals. Such as gravity, pressure, liquid level, material characteristics, etc. It cannot process or output electrical signals. Therefore, pressure sensors usually need to be used in conjunction with other equipment to monitor and control pressure parameters.

The pressure transmitter amplifies the weak electrical signal collected by the pressure sensor in order to transmit or activate the control component. Or convert the non-electricity input from the sensor into an electrical signal. A signal source that is simultaneously amplified for remote measurement and control. Analog quantities can also be converted into digital quantities as needed.

Structurally, the pressure sensor may be part of a pressure transmitter. The pressure sensor only senses pressure signals. And convert the pressure signal into a usable electrical signal according to certain rules. The pressure transmitter can convert the pressure signal into a standard electrical signal and transmit it to the electronic device. Installing another display can output readable data.

In addition, pressure transmitters have a wider range of applications. For example, it has also been widely used in the measurement of liquid level, flow and other fields.

Pressure Transducer Output Signal Types

Pressure sensors convert non-electrical physical quantities such as temperature, pressure, liquid level, materials, gas characteristics, etc. into electrical signals. But this electrical signal is not the easiest to use for pressure monitoring and control in our industrial processes.

Therefore, we generally do not consider the signal output of the pressure sensor. Instead consider Pressure Transducer Output Signal.

The signal output of the pressure transmitter mainly includes the following categories:

- Millivolt output: This is the most common output signal of a pressure transmitter. The millivolt value of the output is linearly related to the measured pressure. It has strong stability and repeatability. Suitable for higher precision measurements.

- Current output: Current output pressure transmitters usually output 0~10mA or 4~20mA DC signals. There is a linear relationship between this type of output signal and the measured pressure. Widely used in industrial control and measurement systems.

- Frequency output: The frequency output pressure transmitter can output a square wave signal of a certain frequency, which changes according to the pressure change. This output method has high anti-interference ability. Suitable for higher precision measurements.

- Digital output: The digital output pressure transmitter 3 can output various digital signals. Such as RS485, CAN, Hart, etc. This type of output signal has high accuracy and reliability. But corresponding interface circuits are required.

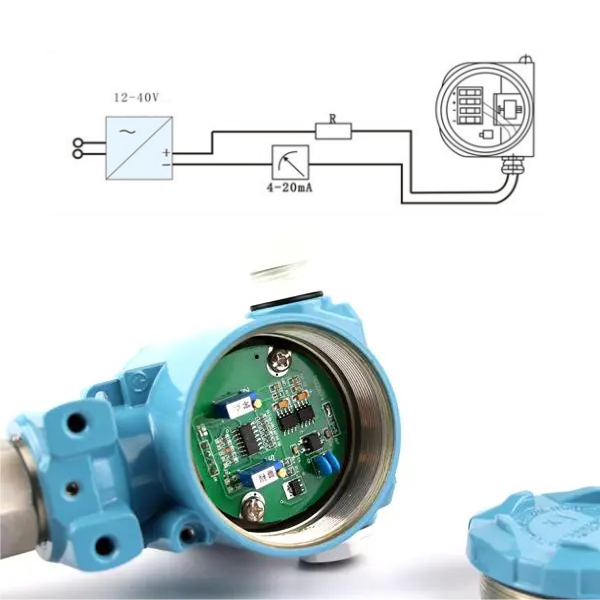

Current output and voltage output signals are collectively called analog signals. The RS485 digital output signal is a digital signal. 4-20mA and RS485 are the most commonly configured signal outputs of intelligent pressure transmitters.

Pressure transmitter 4~20mA

Current output is the most commonly used signal output method for pressure transmitters. The current output signal is less susceptible to parasitic thermocouples and resistance voltage drops and temperature drift along wires. Less interference from external signals. Even if the cable length is long, it will not affect the transmission quality of the measurement signal.

Pressure transmitter RS485

The RS485 output signal is a digital type. It has strong anti-interference ability; it is easy to combine and process with computers; it is easy to store information. In the signal processing of modern technology, digital output signals play an increasing role in pressure transmitters.

It should be noted that the wiring method for each type of output signal is completely different. Users should pay attention to the distinction during installation.

Featured Pressure Transducers

More Pressure Measurement Solutions

- Industrial Smart Pressure Transmitters 4-20mA, HART, RS485 Modbus

- What Is Temperature Compensation and Pressure Compensation for Flow Meters?

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

The output signal selection of the pressure transmitter is determined based on the specific application needs and control system requirements.

When choosing Pressure Transducer Output Signal, you need to consider multiple factors such as measurement range, accuracy requirements, environmental requirements, equipment connections, and cost factors, and make a suitable choice after comprehensive consideration.

By correctly selecting Pressure Transducer Output Signal, the reliability and accuracy of the control system can be improved to meet the needs of industrial automation process control.

The pressure transmitter produced by Sino-Inst supports various output signal configurations. If you need to purchase industrial pressure transmitters or have related technical questions, please feel free to contact our engineers!

-1.jpg)