Flow meters are necessary tools used across various industries to measure the rate at which a fluid (liquid or gas) moves through a system. Among the different types of flow meters, analog flow meters stand out due to their simpleness, reliableness, and broad range of applications.

In this blog post, we will dig into the specifics of analog flow meters, including analog water flow meters and analog gas flow meters. And talk about their benefits and uses.

What is an analog flow meter?

Analog signal output is one of the most common flow meter output signal types. It converts the flow rate into a standard voltage or current signal output through a transmitter, usually 4-20mA or 0-10V.

What sets analog flow meters apart is their power to supply a continuous and analog output signal, offering real-time data regarding the flow rate.

Analog signal output has the advantages of high accuracy, good stability, and strong anti-interference, and is suitable for occasions where long-distance signal transmission is required.

Featured Kinds of Analog Flow Meters

- Differential Pressure Flow Meters: These meters measure the pressure drop across a limitation in the flow path. The flow rate is measured based on this pressure drop. They are usually used in both liquid and gas applications.

- Mechanical Flow Meters: These meters use mechanical constituents, such as positive displacement mechanisms, to measure flow rate. They are known for their enduringness and are often used in water and oil applications.

- Electromagnetic Flow Meters: These meters use Faraday’s law of electromagnetic induction to measure flow rate. They are extremely accurate and are typically used for conductive liquids, such as water and wastewater.

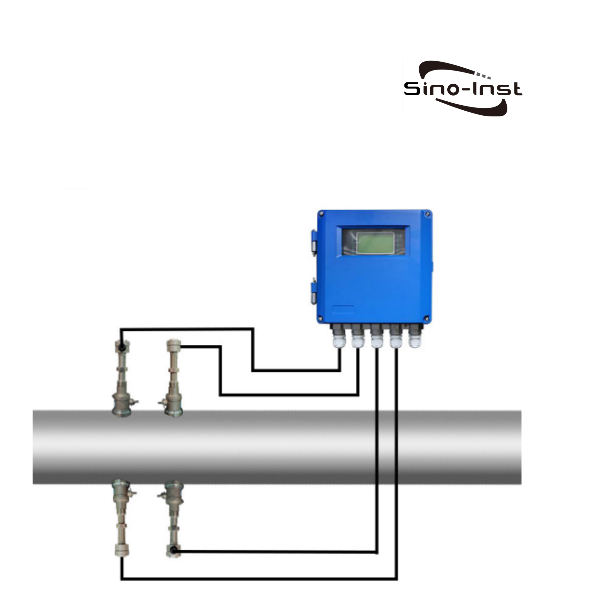

- Ultrasonic Flow Meters: With the sound waves transit time principle to determine the flow rate. Ultrasonic flow meters, with easy installation, could be clamp on, handheld, and portable.

- Mass Flow Meters: Coriolis Mass flowmeters are ideal for liquid flow measuring applications. And Thermal Mass flowmeters are for compressed gas applications. Thermal mass flow meters are available in types of in-line, insertion, and remote mount transmitter.

- Turbine Flow Meter: Turbine flow meter is the most popular equipment to measure inline flow electronically. Turbine flow meters measure the velocity of liquids, gases and vapors in pipes. Such as hydrocarbons, chemicals, water, cryogenic liquids, air, and industrial gases.

- Vortex Flow Meters: Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. As fluid moves across a vortex meter shedder bar, vortices form. The frequency of the vortices shedding is proportional to the fluid velocity.

Types of flowmeter signal output

In industrial production and laboratories, flowmeters are an indispensable instrument. It can measure the volume or mass flow of fluids and convert it into electrical signal output for automatic control of control systems.

However, different types of flowmeters have different output signals.

There are mainly the following types of flowmeter signal output:

- Analog signal output

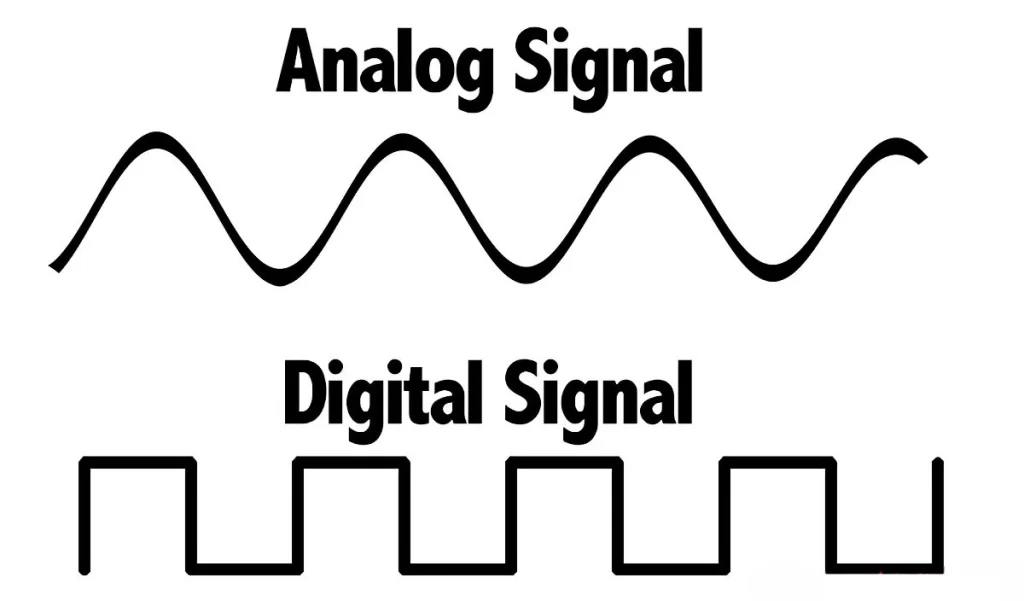

Analog signal output is one of the most common types of flowmeter output signals. It converts the flow rate into a standard voltage or current signal output through a transmitter, usually 4-20mA or 0-10V.

Analog signal output has the advantages of high precision, good stability, and strong anti-interference. It is suitable for occasions where long-distance signal transmission is required.

- Frequency signal output

Frequency signal output is another common type of flowmeter output signal. It converts the flow rate into a pulse signal output of a certain frequency through a transmitter, usually 1kHz or 10kHz.

Frequency signal output has the advantages of fast response speed and strong anti-interference. It is used in occasions where fast response is required.

- Digital signal output

Digital signal output is a new type of flow meter output signal type in recent years. It outputs the flow value through a digital interface, usually RS485 or Modbus protocol.

Digital signal output has the advantages of long transmission distance and strong anti-interference. It is suitable for occasions requiring multi-point monitoring.

- Switch signal output

Switch signal output is a simple flow meter output signal type. It outputs the high and low states of the flow through the switch quantity, usually NPN or PNP output.

Switch signal output has the advantages of simple output and easy control. It is suitable for occasions requiring simple control.

Different types of flow meter output signals have their own advantages and disadvantages. The appropriate signal type should be selected according to the actual application.

Benefits of Analog Flow Meters

- Continuous Output: The analog output provides a continuous signal that can be easily integrated with other analog control systems and instruments.

- Simplicity: Analog flow meters are relatively simple devices, making them easy to install, operate, and maintain.

- Reliability: These meters are known for their robustness and reliability, especially in harsh industrial environments.

- Cost-Effectiveness: Analog flow meters are generally less expensive than their digital counterparts, making them a cost-effective solution for many applications.

Utilization of Analog Water Flow Meters

- HVAC Systems: In HVAC systems, water flow meters are used to measure and control the flow of chilled or heated water, ensuring optimal performance and energy efficiency.

- Water Treatment Plants: Accurate measurement of water flow is crucial in water treatment processes to ensure the correct dosing of chemicals and efficient filtration.

- Irrigation Systems: Monitoring the flow rate in irrigation systems helps in the efficient use of water resources, preventing over or under-watering of crops.

Analog Gas Flow Meter’s Applications

- Industrial Gas Applications: In industries such as chemical manufacturing, precise measurement of gas flow is crucial for process control and safety.

- Environmental Monitoring: Gas flow meters are used to monitor emissions and ensure compliance with environmental regulations.

- Natural Gas Distribution: Accurate measurement of natural gas flow is essential for billing and regulatory compliance in gas distribution networks.

More Featured Flow Measurement Solutions

- Industrial Hydraulic Flow Meters | Mechanical & Digital

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Irrigation Flow Meters-Indispensable for Modern Agriculture and Irrigation

- Ultrasonic Flow Meters: Doppler Effect vs Transit Time

- Doppler Effect Ultrasonic Flow Meters | Sino-Inst

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

Analog flow meters, considering analog water flow meters and analog gas flow meters, are skilled and reliable instruments for measuring fluid flow in different industrial applications. Their simplicity, robustness, and cost-effectiveness make them an captivating choice for many users.

When picking an analog flow meter, it is primary to consider the particular necessities of your usage and follow best exercises for installation and maintenance to ensure accurate and reliable operation.

Whether you are managing a water treatment plant, an irrigation system, or an industrial gas process, Sino-Inst analog flow meters can cater the faithful and trustworthy measurements you want to optimize your operations.

-1.jpg)