Rotary flow meter, also known as “triaxial scraper flow meter”, is a volumetric flow meter, also known as positive displacement flow meter, which can continuously measure the flow rate of liquid in closed pipes.

Rotary flow meter is mainly composed of two parts: measurement and accumulation. The flow meter machine has low friction, long service life, and strong adaptability to viscosity changes. It is widely used in the measurement of transit trade settlement of various crude oils and refined oils. The flowmeter can provide on-site indication, and can also be connected to an explosion-proof pulse or 4~20mA transmitter for remote measurement to achieve automated control.

Rotary Flow Meter technical parameters

The accuracy of the flow meter has nothing to do with the viscosity of the fluid:

Because the TRotary flow meter has the smallest shear surface and smooth flow characteristics.

The low-viscosity Rotary flow meter can accurately measure media with a viscosity <2mPa.s.

The standard type can measure media of 2~200mPa.s.

The high-viscosity type can measure media up to 200.35 million mPa.s according to different environments.

Temperature changes do not compromise the accuracy of the meter. All key components of the Rotary flow meter have a common expansion coefficient. The medium can be accurately measured without correction when the medium is between -40℃~+80℃. After correction, the applicable medium temperature can be as high as 3350℃.

Accuracy

The accuracy indicators of the three-rotor flowmeter are as follows:

When the measurement range is 10:1, ±0.2%;

When the measurement range is 20:1, ±0.5%;

Repeatability: better than ±0.03%

Technical Parameters

| Measuring medium | Crude oil, asphalt, glue, ink, paper pulp, animal feed, cement mixture, liquefied petroleum gas, chemical process, toothpaste, petroleum, cosmetics, fuel oil, lubricating oil, aviation refueling, pharmaceuticals, beverages, food, alcohol, liquefaction Gas, paint and other acids, alkali, salt, water, oil and other liquid media. |

| Nominal pressure MPa | 1.6, 2.5, 4.0 |

| Operating temperature ℃ | -20℃~+80℃; -20℃~+200℃ (can be equipped with high temperature radiator) |

| Medium viscosity | Ordinary type: 0.3~2000mPa.s High viscosity type: >2000.35 million mPa.s |

| Commonly used calibers | 20, 25, 40, 50, 80, 100 |

| Flange standard | GB/T9113.1-2000 (Chinese standard flange) or designed according to user requirements |

| Main material | Ontology Standard type: steel Special type: aluminum, copper, stainless steel rotor Standard type: stainless steel Special type: aluminum, copper, cast iron |

| counter | DH6400 intelligent flow electronic display |

| Output model | Pulse signal, 4~20mA (two-wire or four-wire), supports RS232, RS485 communication (optional) |

| Explosion-proof level | Exd IIC T6 Gb |

| Protection level | IP65 |

| Compensation range | Mechanical temperature compensation: -30℃~+120℃ |

The relationship between pressure loss, flow rate and viscosity of Rotary Flow Meter

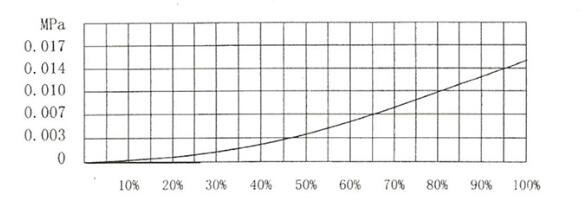

(1) Relationship between pressure loss and flow rate

When the flow meter is working, the pressure loss increases with the increase of flow rate. The relationship between pressure loss and flow rate is as shown in the figure.

(The abscissa is the rated flow rate, the ordinate is the pressure loss)

The calibrated medium viscosity for the above pressure loss is 1MPa.S, which is applicable to all models of Rotary Flow Meter.

(2) Relationship between pressure loss and viscosity

The viscosity of the medium under the same flow rate is different, and the pressure loss is also different.

The calculation formula is: pressure loss = conversion factor of pressure loss × actual viscosity at 1MPaS.

The pressure loss generated by the filter is basically the same as that of a flow meter of the same diameter.

Rotary Flow Meter Flow Range

| Table 1: Accuracy level 0.2 | |||

| Diameter | Flow Range m³/h | ||

| 0.3-2(mPa.s) | 2-8(mPa.s) | 8-2000(mPa.s) | |

| TWS20 | 1-2 | 0.66-2 | 0.4-2 |

| TWS25 | 3-6.0 | 2-6.0 | 1.2-6 |

| TWS40 | 9-15 | 5-15 | 3-15 |

| TWS50 | 12-23 | 8-23 | 5-23 |

| TWS65 | 20-40 | 13-40 | 8-40 |

| TWS80 | 30-60 | 20-60 | 12-60 |

| TWS100 | 50-100 | 30-100 | 20-100 |

| Table 2: Accuracy level 0.5 | |||

| Diameter | Flow Range m³/h | ||

| 0.3-2(mPa.s) | 2-8(mPa.s) | 8-2000(mPa.s) | |

| TWS20 | 0.4-2 | 0.25-2 | 0.2-2 |

| TWS25 | 1.2-6 | 0.75-6 | 0.6-6 |

| TWS40 | 2.5-15 | 1.9-15 | 1.5-15 |

| TWS50 | 5-23 | 2.9-23 | 2.3-23 |

| TWS65 | 8-40 | 5-40 | 4-40 |

| TWS80 | 12-60 | 7.5-60 | 6-60 |

| TWS100 | 20-100 | 12.5-100 | 10-100 |

Rotary Flow Meter working principle

The Rotary Flow Meter measuring chamber consists of a cylindrical cavity and three synchronously rotating rotors. Three rotors are installed in the cylindrical rotor chamber. The leak-proof rotor gear is installed at the end of the leak-proof rotor. The displacement rotor gear is mounted on the end of the displacement rotor. Through such a gear rotation structure, the three rotors can maintain synchronous rotation.

The number of teeth on the leak-proof rotor gear is twice the number of teeth on the rotor gear per displacement. Therefore, the rotation speed of the leak-proof rotor is half the rotation speed of the rotor for each displacement.

When the fluid flows into the measurement chamber, the three rotors rotate synchronously, and the fluid is divided into three parts by the three rotors. As the rotor rotates, the fluid in the measuring chamber moves simultaneously until it is discharged (as shown in the figure).

Since the volume of the measuring chamber is known, the same volume of fluid is displaced per revolution of the rotor. By measuring the number of rotations of the leak-proof rotor, the flow rate of fluid through the measuring chamber can be accurately measured.

The rotation of the leak-proof rotor passes through the gears and other transmission shafts on its rotating shaft. Transfer it to the counter for counting and output a standard pulse signal.

More Featured volumetric flow meters

- What Is the Flow Rate? Velocity vs Flow

- Insertion type flow meters

- Orifice Plate Installation Guidelines

- Installation Instructions for Electromagnetic Flowmeters

- Water Flow Measurement Solution-Ultrasonic Flowmeter

- Slurry & Sludge Flow Measurement

- High-Pressure Flow Meters

- Cooling Water Flow Measurement

- Industrial Nitrogen Flow Meters

- Industrial Nitrogen Gas Flow Meters

- Industrial Liquid Nitrogen Flow Meters

- Flowmeters for Cryogenic Fluids Flow Measurement

- Flow Meters for Domestic Water-Potable Water-Drinking Water

- Inline Compressed Air Flow Meters

- High Viscosity Flow Meters

- Diesel Flow Meter

Rotary flow meter, also known as “triaxial scraper flow meter”, is a volumetric flow meter, also known as positive displacement flow meter, which can continuously measure the flow rate of liquid in closed pipes.

Rotary flow meter is mainly composed of two parts: measurement and accumulation. The flow meter machine has low friction, long service life, and strong adaptability to viscosity changes. It is widely used in the measurement of transit trade settlement of various crude oils and refined oils. The flowmeter can provide on-site indication, and can also be connected to an explosion-proof pulse or 4~20mA transmitter for remote measurement to achieve automated control.

Rotary flow meter is a new type of flow meter developed by our company using advanced volumetric flow measurement technology. Supports parameter customization for DN20~DN100. It can provide on-site instructions, and can also be connected to an explosion-proof pulse or 4~20mA transmitter for remote measurement to achieve automated control.

Our Sino-Inst Rotary flow meters can be widely used in automobiles, adhesives, agriculture, asphalt, aviation fuel, animal feed, beverages, cosmetics, chemicals, concrete, dairy products, liquid fertilizers, food, oil transportation, general industry , flow measurement of liquids in hydrocarbon processing (refining), liquefied gas, lubricants, shipping, paint, petroleum, petroleum products, pharmaceuticals, printing inks, papermaking, solvents, recycling, railways, textiles and other industries.

If you need to purchase Rotary flow meters or have related technical questions, please feel free to contact us.

Rotary Flow Meter-Adaptable to Viscosity Changes-DN20~100

Rotary flow meter, also known as "triaxial scraper flow meter", is a volumetric flow meter, also known as positive displacement flow meter, which can continuously measure the flow rate of liquid in closed pipes.

Product SKU: Rotary Flow Meter - Strong Adaptability to Viscosity Changes-DN20~DN100

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 2599

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)