Digital Gas Mass Flowmeter can accurately measure and control gas mass flow. It can measure corrosive gases, including ammonia, hydrogen sulfide, sulfur dioxide, etc. Small diameters such as φ3, φ6, φ8, φ10, and φ12 are available.

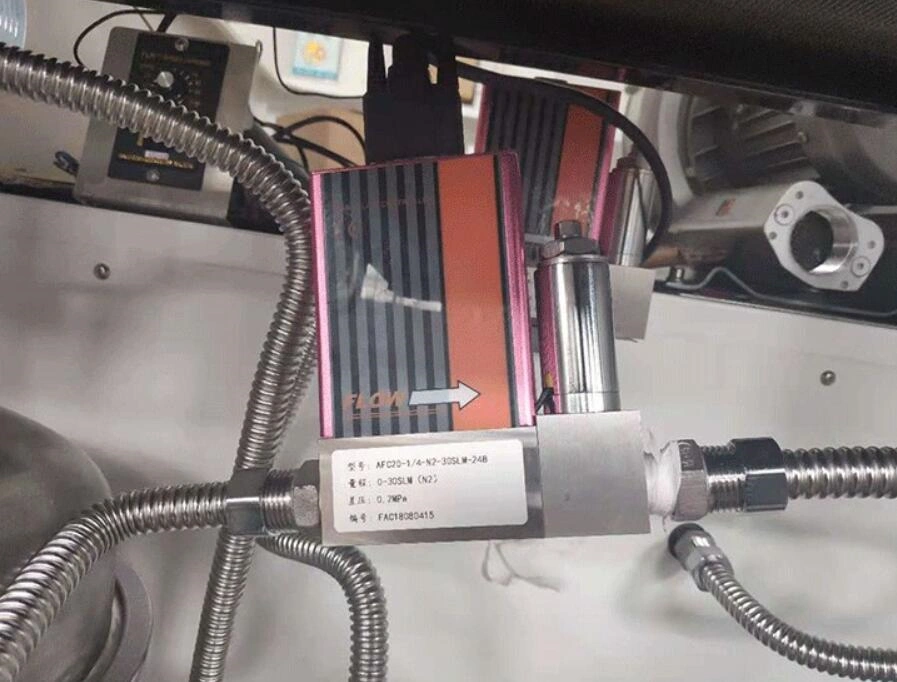

Can be configured as a mass flow meter or Gas Flow Controller (MFC). Our Digital Gas Mass Flowmeter is easy to install, low maintenance and accurate reading. It has an integrated display, pulse and 4-20mA output. It is a simple and economical solution for real-time measurement and control of mass flow. Support OEM.

Features

Digital Gas Mass Flowmeter-Mass Flow Controller Technical Parameters

Digital Gas Mass Flowmeter-Low Range Model

| Product type | Mass Flow Controller | Mass Flow Meter | ||||||||

| Measuring range | 100SCCM ~30SLM; (0~5,10,20,30,50,100,200,300,500…) SCCM | |||||||||

| Measurement and control range | Controller range ratio 50:1 | Flow measurement range ratio 100:1 | ||||||||

| Accuracy | ±1.0%F.S | |||||||||

| Linear | ±0.5%F.S | |||||||||

| Repeat accuracy | ±0.2%F.S | |||||||||

| Response time | Flow controller: <0 .2s | Flow meter: <0.8s | ||||||||

| digital quantity | RS232/485, MODBUS protocol | |||||||||

| Analog quantity | 0 ~5V、 4-20mA、 1 ~5V | |||||||||

| powered by | ±15VDC , 24VDC | |||||||||

| Operating temperature | 0 ~50℃ | |||||||||

| work pressure | Working pressure difference: 0.05~0.5MPa | Working pressure drop: <0.01Mpa | ||||||||

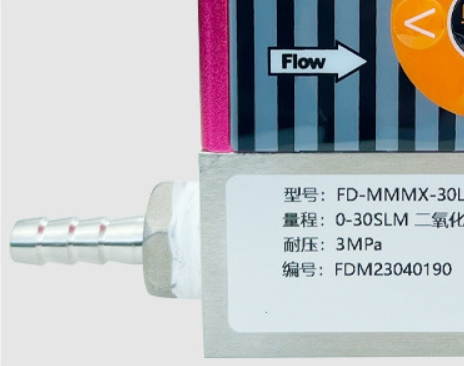

| Maximum withstand voltage | 3MPa/ 10MPa | |||||||||

| Electrical connections | DB15 hole | |||||||||

| Leak rate | 1 × 10-9 Pa m3/S | |||||||||

| Temperature Coefficient | ±0.025%F.S/℃ | |||||||||

| Base material | Stainless steel | |||||||||

| Sealing material | Fluorine rubber, neoprene rubber, nitrile rubber | |||||||||

| Connector | φ3 , φ6 , 1/8″ , 1/4″ | |||||||||

Digital Gas Mass Flowmeter-Middle Range Model

| Product type | Mass Flow Controller | Mass Flow Meter | |||||||

| Measuring range | 30SLM ~300SLM | ||||||||

| Accuracy | ±1.5%F.S | ||||||||

| Linear | ±0.5%F.S | ||||||||

| Repeat accuracy | ±0.2%F.S | ||||||||

| work pressure | Working pressure difference: 0.05~0.5MPa | Working pressure drop: <0 .01Mpa | |||||||

| Response time | Flow controller: <2s | Flow meter: <0.8s | |||||||

| digital quantity | RS232/485, MODBUS protocol | ||||||||

| Analog quantity | 0 ~5V、4-20mA、 1 ~5V | ||||||||

| powered by | ±15VDC ,24VDC | ||||||||

| Operating temperature | 0 ~50℃ | ||||||||

| Maximum withstand voltage | 3MPa/ 10MPa | ||||||||

| Electrical connections | DB15 hole | ||||||||

| Leak rate | 1×10-9Pa m3/S | ||||||||

| Temperature Coefficient | ±0.025%F.S/℃ | ||||||||

| Base material | Stainless steel | ||||||||

| Sealing material | Fluorine rubber, neoprene rubber, nitrile rubber | ||||||||

| Connector | φ8 , φ10 , φ12 | ||||||||

| Measurement and control range | Controller range ratio 50:1 | Flow measurement range ratio 100:1 | |||||||

Digital Gas Mass Flowmeter- High Range Model

| Product type | Mass Flow Controller | Mass Flow Meter | |||||||

| Measuring range | 500SLM ~3000SLM | ||||||||

| Measurement and control range | Controller range ratio 50:1 | Flow measurement range ratio 100:1 | |||||||

| Accuracy | ±1.0%F.S | ||||||||

| Linear | ±0.5%F.S | ||||||||

| Repeat accuracy | ±0.2%F.S | ||||||||

| Response time | Flow controller: <2s | Flow meter: <0.8s | |||||||

| digital quantity | RS232/485, MODBUS protocol | ||||||||

| Analog quantity | 0 ~5V、4-20mA、 1 ~5V | ||||||||

| powered by | ±15VDC ,24VDC | ||||||||

| Operating temperature | 0 ~50℃ | ||||||||

| work pressure | Working pressure difference: 0.05~0.5MPa | Working pressure drop: <0 .01Mpa | |||||||

| Maximum withstand voltage | 3MPa/ 10MPa | ||||||||

| Electrical connections | DB15 hole | ||||||||

| Leak rate | 1×10-9Pa m3/S | ||||||||

| Temperature Coefficient | ±0.025%F.S/℃ | ||||||||

| Base material | Stainless steel | ||||||||

| Sealing material | Fluorine rubber, neoprene rubber, nitrile rubber | ||||||||

| Connector | φ12, Flange Installation | ||||||||

What is a gas flow controller?

A gas mass flow controller is a high-precision, high-stability flow control device. It can accurately measure and stably control the gas mass flow within the set flow range. It is also called a gas mass flow controller (MFC). Compared with traditional volume flow controllers, MFC is not affected by changes in gas temperature and pressure and can more accurately reflect the actual flow of the gas.

Digital Gas Mass Flowmeter-Mass Flow Controller working principle

The excellent accuracy, robustness and reliability of gas mass flow controllers come from our unique sensor probes. The sealed probe consists of two sensing elements, a speed sensor and a temperature sensor, which can automatically correct the effects of temperature and pressure changes.

The instrument circuit heats the speed sensor to a constant value above the gas temperature and then measures the cooling effect of the gas flow. The flow rate is calculated based on the principle that the electrical power consumed to maintain a constant temperature difference is proportional to the mass flow rate of the gas.

Both sensors are standard grade platinum resistance temperature detectors (RTDs). Platinum RTD wire is wrapped around a strong ceramic mandrel for strength and reliability. The entire sensor is sealed in a 316 stainless steel packaging case.

Digital Gas Mass Flowmeter-Mass Flow Controller Application

Digital Gas Mass Flowmeter – A mass flow controller (abbreviated as MFC) is used for precise measurement and control of the mass flow of gases.

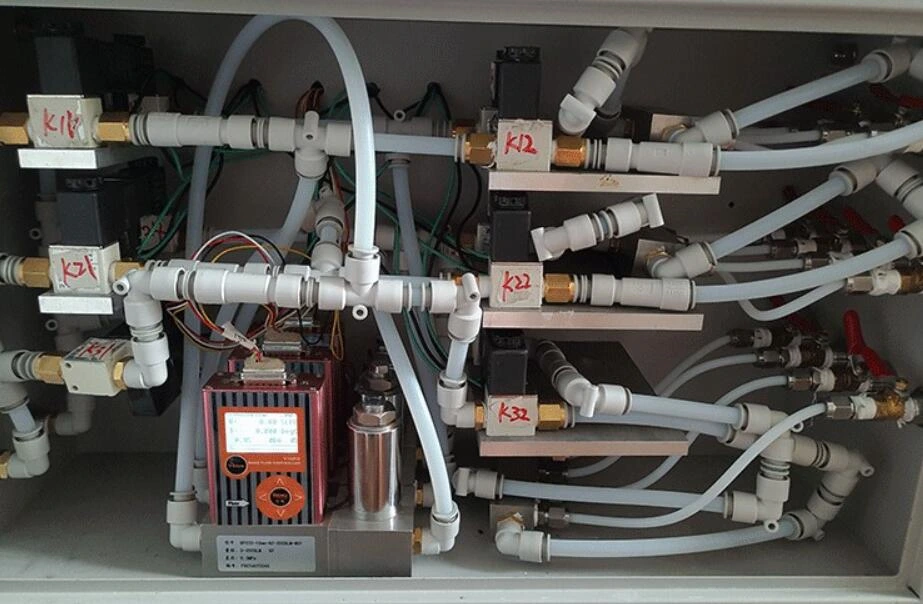

They play an important role in scientific research and production in various fields such as semiconductor and integrated circuit industry, special materials discipline, chemical industry, industry, medicine, environmental protection and vacuum lamps.

Typical applications include:

- Electronic process equipment, such as diffusion, epitaxy, CVD, oxidation, plasma etching, sputtering, and ion implantation;

- Coating equipment, optical fiber smelting, micro-reaction devices, gas mixing and distribution systems, capillary measurement, gas chromatograph, and other analytical instruments;

What is the difference between mass flow and volume flow?

Volume flow refers to the flow in which the amount of fluid is expressed in volume. Volume flow is expressed by the formula: qv=V/t=u×A, where: qv is the volume flow, m3/s; V is the unit flow volume, m3; t is the unit time, s; u is the average flow velocity in the pipe, m/s; A is the cross-sectional area of the pipe, m2.

Mass flow refers to the flow in which the amount of fluid is expressed in mass. Mass flow can be expressed by the formula: qm=m/t=ρ×u×A, where qm is the mass flow, kg/s; m is the unit fluid mass, kg; ρ is the fluid density, kg/m3; t is the unit time, s; u is the average flow velocity in the pipe, m/s; A is the cross-sectional area of the pipe, m2.

How to convert volume flow and mass flow:

- If the mass flow of the flow is known and needs to be converted to volume flow, the following formula can be used: qv=qm/ρ, where qv is the volume flow, m3/s; qm is the mass flow, kg/s; ρ is the fluid density, kg/m3.

- If the volume flow of the fluid is known and needs to be converted to mass flow, the formula can be used: qm=qv×ρ

More about Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion.

More Featured Flow Meters and Solutions

- Flowmeter Selection Guide | Find the Best One for Your Application

- 11 Flow Meter Types and Their Advantages and Disadvantages

- Top 3 Flow Meters for PVC Pipes

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Top 4 Types of Pipeline Flow Meters-DN6~DN1000~DN6000

- Flow Measurement 101

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- What Is Solvent Flow Meter? Industrial Selection Guide

- What Is a BTU Meter? | BTU Energy Measurement Systems

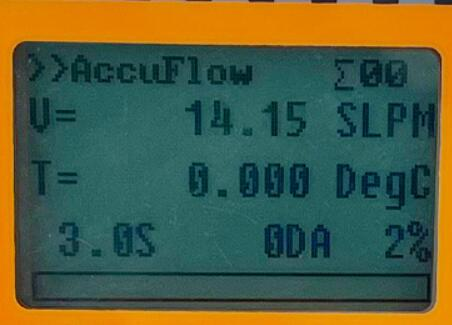

Digital Gas Mass Flowmeter- Gas flow controller (abbreviated as MFC) is an analog and digital compatible design. It can display instantaneous flow and cumulative flow through analog secondary instruments and PLC and can also communicate directly with the computer through a digital interface.

Our Sino-Inst Digital Gas Mass Flowmeter-mass flow controller adopts multiple gas and multiple range design solutions to easily meet the user’s on-site use needs. The measuring range is optional (0~5, 10, 20, 30, 50, 100, 200, 300, 500…) SCCM; (0~1, 2, 3, 5, 10, 50, 100, 200, 500, 1000… 3000) SLM; supports customization of other parameters.

If you need to purchase a Digital Gas Mass Flowmeter-mass flow controller or have related technical questions, please feel free to contact us.

Digital Gas Mass Flowmeter-Gas Flow Controller | Sino-Inst

Digital Gas Mass Flowmeter-mass flow controller (MFC) is used for precise measurement and control of the gases mass flow. φ3, φ6, φ8, φ10, and φ12 are available.

Product SKU: Digital Gas Mass Flowmeter-Mass Flow Controller

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 1299

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)