Capacitive pressure transmitter is a type of pressure measuring instrument that measures pressure by measuring changes in capacitance. The deformation of the isolator caused by pressure is used to change the capacitance value. The pressure value is measured by measuring the change in capacitance and converting it into a corresponding electrical signal output.

Capacitive pressure transmitter is suitable for measuring pressure, differential pressure and absolute pressure of various liquids, gases and steams.

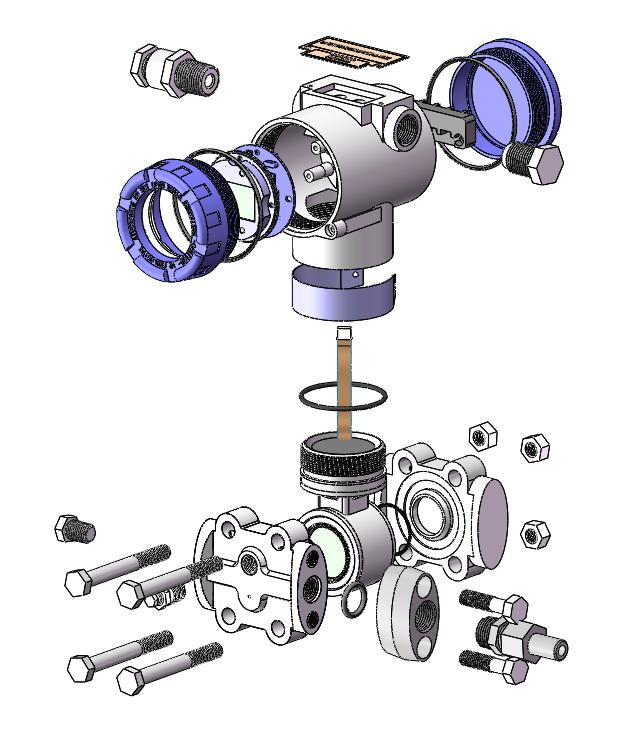

Capacitive Pressure Transmitter/Differential Pressure Transmitter Structure

The two pressures of the measured medium pass into the high and low pressure chambers and act on the isolation diaphragms on both sides of the delta element (ie, the sensitive element). The filling liquid in the separator and element is transferred to both sides of the measuring diaphragm.

The capacitive pressure transmitter is a capacitor composed of a measuring diaphragm and electrodes on both sides of the insulating sheet. When the pressure on both sides is inconsistent, the measuring diaphragm will be displaced, and its displacement is proportional to the pressure difference. Therefore, the capacitance on both sides is not equal, and through the oscillation and demodulation links, it is converted into a signal proportional to the pressure.

The working principle of the capacitive pressure transmitter is the same as that of the differential pressure transmitter, except that the pressure in the low pressure chamber is atmospheric pressure or vacuum. The A/D converter of the capacitive pressure transmitter converts the demodulator current into a digital signal, the value of which is used by the microprocessor to determine the input pressure value. A microprocessor controls the operation of the transmitter. Additionally, it performs sensor linearization. Reset measuring range. Engineering unit conversion, damping, square root, sensor trimming and other operations, as well as diagnostics and digital communications.

Below are our Sino-Inst’s Capacitive pressure transducer diagram.

Of course, in addition to capacitive pressure transmitters, we at Sino-Inst also produce other types of pressure transmitters. You can continue to check out other types of pressure transmitters:

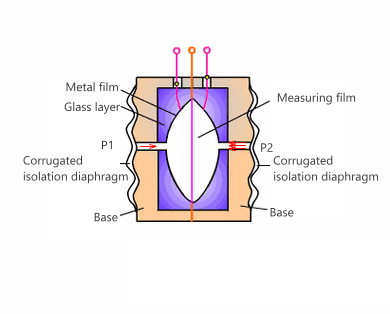

Capacitive Pressure Sensor Working Principle

A capacitor consists of two parallel conductive plates with a small gap between them. Capacitance is defined as:

C=er e o A /d

- e r is the dielectric constant of the material between the plates (1 in vacuum)

- e 0 is the electrical constant, (equal to 8.854×1012 F/m)

- A is the area of the board

- d is the distance between the plates

Changing any variable will cause a corresponding change in capacitance. The easiest thing to control is spacing. This can be achieved by making one or both of the plates into a diaphragm that deflects in response to pressure changes. Typically, one electrode is a pressure-sensitive diaphragm and the other electrode is fixed.

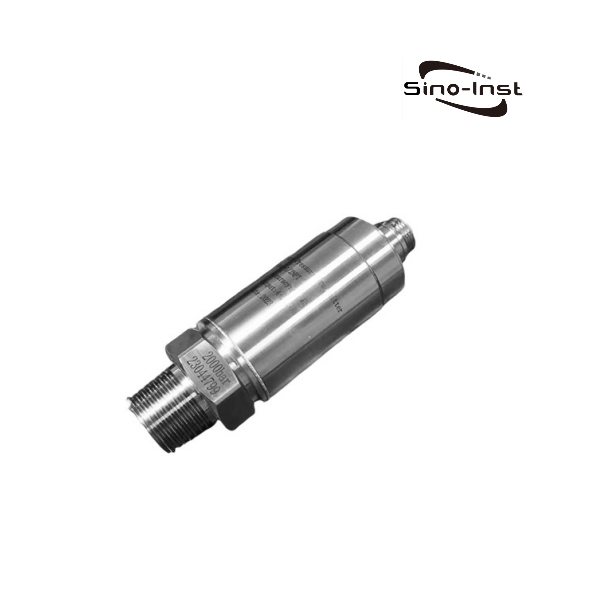

An example of our Sino-Inst capacitive pressure sensor is shown below:

A simple way to measure changes in capacitance is to make it part of a tuned circuit, usually consisting of a capacitive sensor and an inductor. This can change the frequency of the oscillator or the AC coupling of the resonant circuit.

Featured Capacitive Pressure Transmitters/Differential Pressure Transmitters

capacitive pressure sensor advantages and disadvantages

A capacitive sensor is a device that converts a measured change into a change in capacitance, which itself is a variable capacitor. Because this kind of sensor has the characteristics of simple structure, small size, good dynamic response, high sensitivity, high resolution, and can realize non-contact measurement, it is widely used in detection of displacement, acceleration, vibration, pressure, pressure difference, liquid level, etc. field.

More Featured Pressure Measurement Solutions

- Industrial Water Pressure Measurement and Monitoring

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

The capacitive pressure transmitter uses the deformation of the isolator caused by pressure to change the capacitance value. The pressure value is measured by measuring the change in capacitance and converting it into a corresponding electrical signal output.

Capacitive transmitters are mainly used to measure parameters such as pressure, differential pressure, negative pressure, high static pressure, liquid level and absolute pressure of gases, liquids and steam, and then convert them into 4~20mA signal output.

Capacitive transmitters include GP type (gauge pressure), DP type (differential pressure), DR type (micro differential pressure), AP type (absolute pressure), HP type (high static pressure), LT type (flange liquid pressure) position transmitter), DP/GP type (remote differential pressure/pressure transmitter) and other types. The combination of capacitive transmitter and intelligent amplifier board can form an intelligent pressure transmitter, which can communicate with each other through a handheld terminal that complies with the HART protocol for setting and monitoring.

We at Sino-Inst supply various types of capacitive pressure transmitters and differential pressure transmitters. And can be configured with various mounting brackets, flange diaphragms, capillary tubes, etc. If you need to purchase capacitive transmitters, capacitive differential pressure transmitters, or have related technical questions, please feel free to contact us!

-1.jpg)