We often hear about 2 wire ultrasonic level transmitter, 4 wire ultrasonic level transmitter, etc. Ultrasonic level transmitter can be divided into two-wire system, three-wire system and four-wire system.

Ultrasonic level transmitter emits ultrasonic pulses from a sensor. After the sound wave is reflected by the liquid surface, the sensor receives it. Use an overvoltage transistor to convert it into an electrical signal. The distance between the sensor and the measured liquid surface is calculated from the time between the emission and reception of the sound wave. Not affected by the viscosity, density, etc. of the liquid. The application fields are very wide.

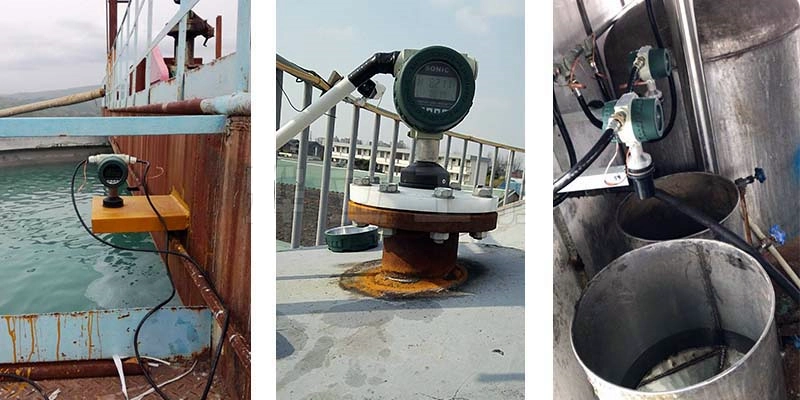

Featured 4 Wire – 3 Wire – 2 Wire Ultrasonic Level Transmitters

Ultrasonic Level Transmitter: 2 Wire – 3 Wire – 4Wire

The power supply (DC24V) and signal output (DC4-20mA) of the two-wire ultrasonic level meter share a circuit. For standard transmitter form. The disadvantage is that the transmitting power is weak and is not suitable for liquid level measurement with large fluctuations. When the liquid level evaporates greatly, the measurement effect is not ideal.

The three-wire ultrasonic level meter uses two wires each for its power supply 24VDC and signal output 4-20mADC. The negative stage of the power supply and the negative stage of the signal share the same line. Its advantage is that the transmitting power is large, and it is suitable for measuring liquid level and material level under various conditions, with good effect.

Four-wire ultrasonic liquid level meter, with 4~20mADC, high and low switching output. When AC 220v power supply is used, or when DC 24v power supply is used and the power supply circuit and signal output circuit are required to be completely isolated, a 4-core cable should be used. Its power supply 220VAC and signal output 4-20mADC each use two lines, and the power negative stage and the signal negative stage are separated. Its advantage is that it has large transmitting power, is suitable for on-site installation, and has independent power supply.

To put it simply, the two-wire system means that the power supply and output have two common wires. The three-wire system is a common ground wire for the power supply and output. The four-wire system has separate power and output.

Read more about: Ultrasonic Level Transducer: Working Principle,Types and Benefits

Relay function of ultrasonic liquid level transmitter

Generally, relays cannot be added to two-wire ultrasonic level gauges. If you need to install a liquid level high and low alarm, you need to choose a four-wire ultrasonic level gauge. Because only four-wire ones can add relays.

The ultrasonic liquid level meter without a relay when shipped from the factory cannot add a relay output by itself. If a relay output is required on site, a secondary instrument with a relay output can be added. The relay output can be set through the secondary instrument.

Examples of four-wire ultrasonic level gauge relay functions:

(1) For a liquid level of 8 meters, it is required that when the liquid level is lower than 2 meters, the relay should be closed to start the pump for water filling, and when the liquid level is higher than 7 meters, the relay should be opened to stop the pump.

This can be achieved using a lower limit alarm relay. Set hysteresis dL = 7 – 2 = 5 meters, set L = 2 meters.

In this way, when the liquid level is less than 2 meters, the relay is closed and the pump is turned on to inject water.

When the liquid level is greater than 7 meters, the relay is disconnected and the pump is stopped.

(2) If the liquid level is 5 meters, if it is higher than 4 meters, the relay will be closed and the pump will start draining. If the liquid level is lower than 1 meter, the relay will be open and the pump will be stopped.

This can be achieved using an upper limit relay. Set hysteresis dH= 4 – 1 = 3 meters, H = 4 meters. In this way, when the liquid level is greater than 4 meters, the relay is closed and the pump is turned on for drainage, and when the liquid level is less than 1 meter, the pump is stopped.

The above two examples are examples of using hysteresis to control two liquid level points when only one pump is used. For situations where multiple pumps are used, the control values can be simply set.

More Level Measurement Solutions

- Liquid Level Controllers and Switches for Industrial Tanks

- Difference Between Radar and Ultrasonic Level Transmitter

- Pressure Transducer Output Signal Guide

- Industrial Ultrasonic Level Transmitters | Non-contact Level Measurement

- Featured 5 Guided Wave Radar Level Transmitter Types

- Guided Wave Radar Level Transmitter Installation Guide and Troubleshooting

- Difference Between Radar and Guided Wave Radar Level Transmitter

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

Sino-Inst’s ultrasonic level transmitter includes ordinary type, explosion-proof type, external type, etc. Two-wire and four-wire signal output can be configured. 4-20mA, RS485, relay and other signal outputs.

Sino-Inst’s 4 wire and 2 wire ultrasonic level transmitters are widely used in manholes, factory water tanks, tanks, municipal engineering, tap water, sewage treatment, water conservancy and hydropower, steel, coal mines, electric power, petrochemical industry, urban rivers and lakes, transportation and food Processing and other industries under working conditions.

If you need to purchase ultrasonic level transmitters, or have related questions, please contact our engineers!

-1.jpg)