What are the advantages and disadvantages of vortex flowmeters? Understanding Vortex Flow Meter Advantages and Disadvantages can help us better choose the right flow meter.

The vortex flowmeter is a volume flowmeter based on the Karman vortex principle to measure the volume flow of gas, steam or liquid, the volume flow under standard conditions, or the mass flow of gas, steam or liquid. A vortex is formed when fluid flows through the collection rod of a vortex flowmeter. The frequency of vortex shedding is proportional to fluid velocity and can be configured for temperature and pressure compensation.

Vortex Flow Meter Advantages

Advantages of vortex flowmeter:

- The pressure loss is small, about 1/4 to 1/2 of the throttling differential pressure flowmeter.

- The output pulse signal is proportional to the flow rate, without zero drift.

- The structure is simple and firm, easy to install and maintain. No pressure guide tube, three-valve manifold, etc., reducing leakage, clogging and freezing. The measuring element has the advantages of simple structure, reliable performance and long service life.

- High precision, generally ±(1~1.5)%R.

- Wide measurement range. A vortex flowmeter with a reasonable caliber has been determined, and the measuring range can reach 20:1.

- Within a certain Reynolds number range, the output frequency of the orifice flowmeter is not affected by the physical properties (density, viscosity) and composition of the fluid. That is, the gauge factor is only related to the shape and size of the vortex generator and piping.

- The volume flow rate of the vortex flowmeter is not affected by thermal parameters such as temperature, pressure, density or viscosity of the measured fluid. Usually, no separate calibration is required. It can measure the flow of liquid, gas or steam.

Vortex Flow Meter Disadvantages

Disadvantages of Vortex Flowmeters

- The volume flow rate of the vortex flowmeter is not affected by the temperature, pressure, density and other thermal parameters of the measured fluid. But the final measurement for liquids or vapors should be mass flow.

For gases, the final measurement should be the standard volume flow.

Both mass flow and standard volume flow must be converted to fluid density. Changes in fluid density due to changes in fluid conditions must be considered. - The main factors causing flow measurement error are:

Measurement error caused by uneven pipeline flow velocity;

The medium density cannot be accurately measured when the fluid working condition changes;

Wet saturated steam is measured assuming dry saturated steam.

If these errors are not limited or eliminated, the total measurement error of the vortex flowmeter will be very large. - Poor vibration resistance.

External vibration will cause measurement errors of the vortex flowmeter, or even fail to work properly.

The high-speed impact of the channel fluid will generate additional vibrations on the cantilever of the vortex generator, which will reduce the measurement accuracy. The effect of large pipe diameter is more obvious. - Poor adaptability to measuring dirty media.

The generating body of the vortex flowmeter is easily soiled by the medium or entangled with dirt. Variations in geometry size have a great impact on measurement accuracy. - High requirements for straight pipe sections.

Experts pointed out that the straight pipe section of the vortex flowmeter must ensure that the front end 40D and 20D meet the measurement requirements. - Poor temperature resistance.

Vortex flowmeters generally only measure the fluid flow of media below 300°C.

Read More About: Vortex Flowmeter Technology

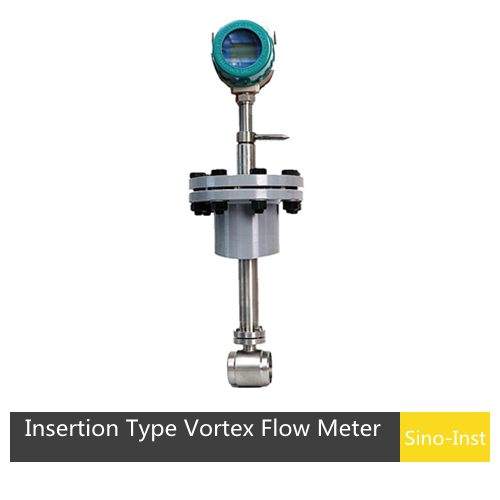

Featured Vortex Flow Meters

More Featured Gas Flow Meters

Flow Measurement Solutions

Vortex flowmeters are also called vortex flowmeters or Karman vortex flowmeters. Sino-Inst is a manufacturer of vortex flowmeters. We offer more than 10 vortex flowmeters. It is mainly used for flow measurement of industrial pipeline media fluids, such as gas, liquid, steam and other media.

Vortex street generally measures steam and water and other media, such as steam generated by thermal power plants. The steam can be reused for heating and production, so thermal power plants can sell steam to outsiders. Therefore, it is necessary to install a flowmeter to measure how much steam is output to the user, that is, to measure the flow of steam, which uses a vortex flowmeter. Of course, there is more than one kind of flowmeter that can measure steam. For example, our tower flowmeter also measures steam, gas, etc.

For the issue of Vortex Flow Meter Advantages and Disadvantages, if you have any thoughts, please share in the comment area!

-1.jpg)