Starting from farming and domestic water distribution to industrial processes and environmental observation, Water flow measurement plays a vital part. It’s all-important to accurately measure water flow to optimize efficiency, cut down costs, and meet restrictive requirements.

There are several methods utilized to measure the flow rate of water, each with its own plus and minuses. Here, we will focus on measuring the water flow rate with an external clamp ultrasonic flow meter.

What is a water flow meter?

A Water Flow Meter is a Flow Meter Designed to Measure the Flow of Water Specifically, as opposed to other liquids (like oil or gasoline).

Water Flow Meters Can be used to track the flow of water within a variety of applications. They can:

Measure usage by individual HouseHolds or Communities with Municipal Drinking Water Systems.

Track Sewage Flow to Help Municipalities Ensure That Their Wastewater Systems Adequately Meet Demand.

Help Factory Operators Assess the Amount of Water Being Use to Cool An Industrial Plant.

There are several Water Flow Meter Technologies to Choose from Depending on the Water Measurement Application, Maintenance Requirements, and budget. After Flow Meters Has a UNIQUE Principle of Operation, application advantage. For example, electromagnetic flowmeters, ultrasonic flowmeters, turbine flowmeters, vortex flow meters, etc.

Among these, CLAMP On Ultrasonic Flow Meters Are Gaining Popularity Due to their Non-Intrusive Nature, Accuracy, And Versositionility.

Featured Ultrasonic Clamp-on Flow Meters for Water

How Ultrasonic Flow Meters Work: Working Principle

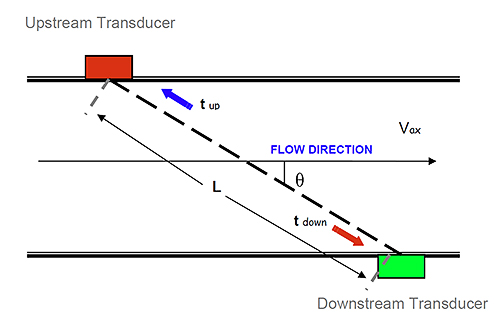

The ultrasonic flow meter runs on the principle of the Doppler effect or transit-time method.

‘Doppler ultrasonic meters’ work on the principle of detecting changes in the frequency of sound waves as they reflect off particles or bubbles in the water. These types of ultrasonic meters are particularly effective when the water contains particulates or bubbles.

In contrast, in ‘transit-time ultrasonic meters’, the flow is calculated by comparing the time taken by ultrasonic signals to travel with and against the flow of water. This difference in time allows for the calculation of the flow rate.

Benefits of Ultrasonic Flow Meter: Edge Over Other Flow Meter

A. Non-invasive Measurement;

B. Accuracy;

C. Versatility;

D. No Moving Parts;

E. Low Pressure Drop;

F. Low-cost measurement of large-caliber pipelines.

Clamp-On Water Flow Meters

Clamp-on water flow meter doesn’t require the meter to be inserted into the pipe or interfere with the flow of water.

How Clamp-On Water Flow Meters Work?

Clamp-on flow meters use ultrasonic waves to function. The transducers are clamped onto the exterior of the pipe and send ultrasonic signals through the pipe. This design is especially beneficial because it gets rid of the need for cutting pipes or discontinuing the flow.

Ultrasonic clamp-on meters are inherently accurate with an impressive accuracy of reading of ± 1% and a repeatability performance of ±0.2%. They maintain accuracy across a wide range of flow applications and have a greater extended low flow accuracy compared to mechanical meters.

Uses of Clamp-On Water Flow Meters

Clamp-On Flow Meters are widely used in industrial settings, HVAC systems, water treatment plants, and irrigation systems.

These are perfect for use in applications where pipes are large, access is limited, or it’s impractical to shut down systems for installation.

Transit time clamp-on flow meters are used to flow clean, single-phase fluids without particulates or bubbles. On the other hand, Doppler Clamp-on flow meters are used for multi-phase fluids containing bubbles or particulates – which is why they are often used for wastewater flows.

Benefits of Clamp-On Water Flow Meters

- Non-Intrusive Installation

- Cost-Effective

- Flexibility

- Portability

The importance of water flow measurement

Water is the most basic resource in every industry. Every industry needs accurate flow monitoring to ensure the operation of the production process. The more accurate the flow meter is, the higher its value to the enterprise or agency.

Agriculture: In applications like agricultural irrigation, too much flow can flood a crop, leading to rot and a wasted harvest. Too little, which starves plants of water, is just as dangerous. Accurate flow meters remove the guesswork to ensure healthy, productive fields.

Wastewater: Accurately measuring the flow of sewage and other types of wastewater is essential for preventing clogs, especially in systems where wastewater includes sludge as well as liquid effluent.

Drinking water: Potable water systems require accurate flow measurements to ensure that the right amount of water reaches each branch and building on the system, even as water consumption rates vary across the systems.

Cooling water: In settings like factories and data centers, cooling water plays a vital role in preventing equipment from overheating—but it only does so if cooling systems deliver just the right volume of water, which requires accurate flow meter readings.

Oil and gas: To manage production and ensure adequate energy supply across large networks, the oil and gas industry must accurately measure flows, even when materials aren’t pure or when liquids travel very long distances.

More Industrial Water Flow Meters

- Digital Water Flow Meter

- Choosing the Right Inline Water Flow Meter

- Cooling Water Flow Measurement

- Sanitary Flow Meter

- Wastewater flow meter

- Water Flow Meter Types

Whether you’re measuring water flow in a home setting, an agricultural irrigation system, or a large-scale industrial process, deciding the right flow meter is central to accurate measurement.

Understanding how to measure and calculate the flow rate of water can help optimize efficiency and reduce costs, making these tools invaluable across a wide array of industries. Sino-Inst is a company, which provides you with perfect water flow meters according to your requirements.

-1.jpg)