In industries such as seawater treatment plants, coastal factories, and shipbuilding systems, seawater monitoring is essential. This includes monitoring seawater pipeline pressure, flow rate, and level.

For example, desalination plants need to monitor influent flow rate, concentrated brine discharge flow rate, and product water flow rate to calculate recovery rates. Shipbuilding systems require monitoring the pressure, temperature, and flow rate of the seawater cooling circulation system for the main engine and auxiliary engines to ensure the normal operation of the power equipment.

Properties of Seawater

- High Corrosivity

Seawater is a strong electrolyte solution rich in chloride ions (Cl⁻), sodium ions (Na⁺), magnesium ions (Mg²⁺), and other salts. It has extremely strong penetrating power to most metals (especially carbon steel and stainless steel), destroying the passivation film on metal surfaces and leading to rapid general corrosion and fatal localized corrosion (such as pitting and crevice corrosion).

Components in direct contact with seawater, such as the sensor body, diaphragm, electrodes, and cable connectors, are highly susceptible to corrosion. This can lead to sensor failure, decreased accuracy, leakage, and even structural damage.

- Impurities and Sediment

Seawater contains a large number of microorganisms (bacteria, algae), larvae (barnacles, oysters, etc.), and suspended particulate matter (sediment, organic matter). These can clog sensor measuring holes or jam mechanical components such as rotors.

- Harsh Measurement Environment

The marine environment is subject to extreme weather conditions such as waves, tides, ocean currents, high hydrostatic pressure (deep sea), and typhoons.

This places extremely high demands on the sensor’s structural strength, sealing performance, and resistance to vibration and shock. Dynamic waves can cause drastic fluctuations in liquid level and pressure measurements.

Seawater Pressure Monitoring

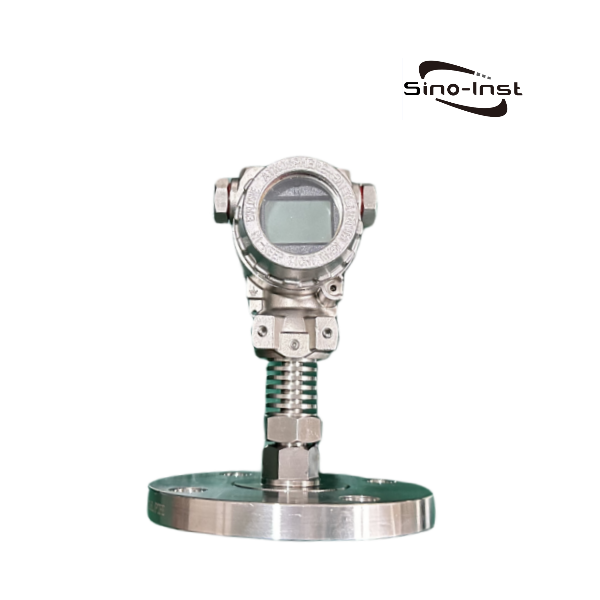

Due to the highly corrosive nature of seawater and the corrosive measurement environment, we need to select specialized materials when choosing seawater pressure transmitters. For example, all-PTFE or all-titanium alloy.

Sino-Inst supports customization of the wetted material and body material of pressure transmitters. We have previously customized PTFE pressure sensors and titanium alloy pressure transmitters for seawater desalination equipment factories.

Case: Sea Water Resistant Pressure Sensors

Seawater Flow Monitoring

Seawater, as a highly corrosive, high-salinity medium that may contain suspended particles, poses a severe challenge to flow measurement equipment.

Electromagnetic flow meters are one solution for seawater measurement. Their characteristics of having no moving parts and being unaffected by fluid density and viscosity make them particularly suitable for seawater environments. High-quality electromagnetic flow meters utilize special corrosion-resistant materials (such as Hastelloy and titanium) and double-sealing technology to effectively resist seawater corrosion.

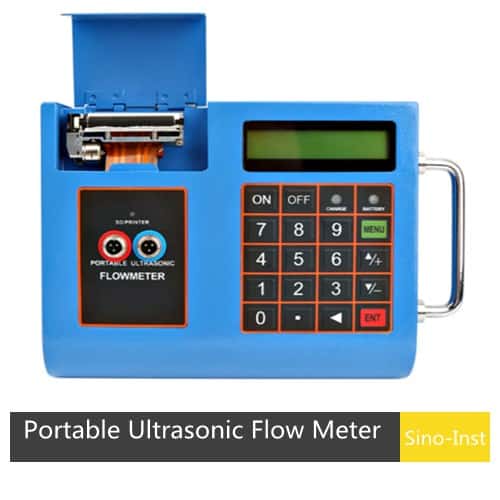

Ultrasonic flow meters are also suitable for seawater measurement, especially the clamp-on design which avoids direct contact with seawater and corrosion problems. Doppler ultrasonic flow meters are particularly suitable for seawater containing suspended particles, while time-of-flight flow meters are more suitable for pure seawater.

The following key factors should be considered when selecting a seawater flow meter:

- Material corrosion resistance rating: Must meet IP68 or higher protection rating;

- Electrode and lining materials: Tantalum electrodes and PTFE lining preferred;

- Installation method: Select full-bore or insertion type based on pipeline conditions;

- Measurement accuracy: Seawater applications typically require ±0.5% or higher precision;

- Maintenance convenience: Consider possibility of online maintenance and cleaning;

Seawater Level Monitoring

Real-time seawater level monitoring is commonly required at marine monitoring stations, ship ballast tanks, and in coastal enterprises such as petrochemical, chemical, and steel plants.

Sino-Inst supplies contact, non-contact, and portable level meters specifically designed for seawater level measurement.

- Submersible Level Transmitter: Based on the principle of hydrostatic pressure, it provides fast and stable measurement of seawater levels. Installation and testing are cost-effective.

- Radar Level Meter: Radar level meters, with their non-contact, high-precision, and strong anti-interference characteristics, are gradually becoming the mainstream solution for seawater level monitoring. Compared to traditional sensors, radar level meters offer significant advantages: unaffected by complex media; unaffected by liquid density, viscosity, foam, or steam; no moving parts, reducing the risk of mechanical failure; stable output in all weather conditions; adaptable to extreme temperatures from -40℃ to 200℃ and humid environments.

- Portable Ultrasonic Depth Meter: Portable design for convenient measurement. The maximum measurement range is up to 300m.

More Solutions

Sino-Inst offers a variety of customized measurement solutions for corrosive liquids such as seawater, including high-temperature, high-pressure, and special installation methods.

If you still haven’t found a suitable seawater measurement product, please feel free to contact us.

-1.jpg)