High viscosity liquids, also known as high-viscosity fluids (HVF), have always been a challenging medium to measure in industrial processes. Examples include honey, adhesives, ointments, chocolate, vegetable and animal oils, tar, and glue.

Sino-Inst provides measurement solutions for viscosity, temperature, pressure, level, and flow rate of high-viscosity liquids.

Common High-Viscosity Liquids and Measurement Challenges

Some common viscous fluids encountered in industrial processes include:

- Petroleum-based: Asphalt, heavy oil, lubricating oil.

- Polymeric: Resin melts, coatings, adhesives.

- Food-related: Honey, sauces, chocolate paste.

- Natural: Rosin, starch paste, gelatin.

- Inorganic: Magma, water glass.

- Industrial slurries: Pulp, drilling mud, sludge.

When measuring these viscous liquids, we are likely to encounter:

- High viscosity of the medium, which can cause it to stick to the measuring instrument.

- High temperatures of the medium. For example, asphalt needs to be at a high temperature of 150-180°C to flow, so asphalt pipelines require heating and insulation.

- High pipeline pressure. Due to the difficulty in pumping viscous media, increased pipeline pressure may be necessary.

- Particulate impurities. High-viscosity liquids may contain particulate matter, which can jam gears and other moving parts.

Of course, the most important thing is to choose a suitable measurement solution based on the actual medium conditions, measurement environment, and measurement requirements.

Viscosity Measurement of High-Viscosity Liquids

An online viscometer is an instrument used to measure the viscosity of liquids. It measures the resistance of the liquid using micro-vibrations generated by a vibration system. In practical engineering and industrial production, it is often necessary to detect the viscosity of fluids online to ensure the operating environment and product quality, thereby improving production efficiency.

The Inline Viscosity Meter supplied by Sino-Inst can measure viscosity in the range of 0-100000 mPa·s. By measuring the liquid viscosity during the online process, data on the rheological behavior of the liquid can be obtained. This data has significant guiding value for process control and transportability in predicting product manufacturing processes.

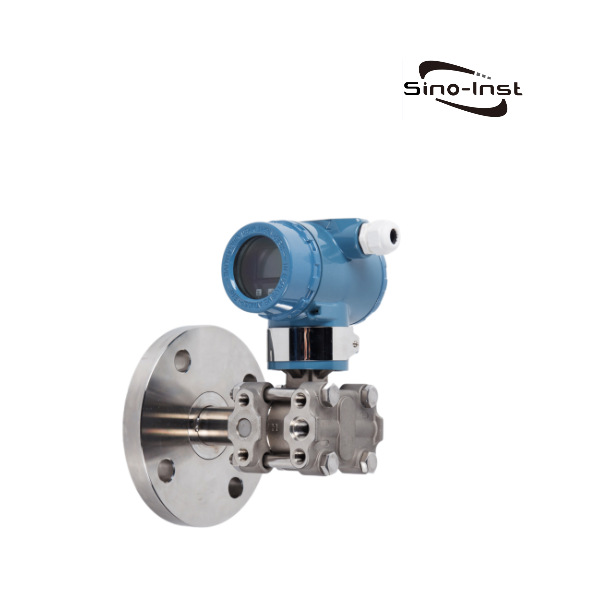

Pressure Measurement of High-Viscosity Fluids

When measuring the pressure of high-viscosity fluids, the main factors to consider are high temperature, particulate impurities, and viscosity. Therefore, our Sino-Inst High Viscosity Fluid Pressure Sensors offer the following advantages:

- Supports customized high-temperature versions. Customization is available for temperatures ranging from 200℃ to 1200℃.

- Utilizes a flat diaphragm pressure sensor. The design eliminates pressure ports, preventing clogging by the medium.

- Supports high-pressure customization. Customization is available in the range of 100MPa to 700MPa.

- Multiple installation methods are available. These include flange mounting, capillary remote mounting, sanitary clamp mounting, and flat diaphragm threaded mounting.

- Compatible wetted materials can be configured based on the chemical properties of the medium. For example, PTFE coating on the flange diaphragm provides corrosion resistance.

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Industrial Smart Pressure Transmitters 4-20mA, HART, RS485 Modbus

- Pressure Sensor Selection: Gauge Pressure vs. Sealed Gauge Pressure

- Top 10 Pressure Transmitter Terminology

- How to Choose the Right Oil Pressure Transmitter for Your Application

- Pressure Transmitter 4-20mA Guide: Testing and Troubleshooting

Flow Rate Measurement of High-Viscosity Fluids

When measuring the flow rate of high-viscosity fluids, we generally have several options: Coriolis mass flow meters, oval gear flow meters, target flow meters, or GF gear flow meters. Each has its own advantages and suitable operating conditions.

- Coriolis Mass Flow Meter

This is the most expensive type of flow meter. However, it has excellent tolerance for viscous fluids. It can measure media with viscosities up to 500,000 cp and allows for particulate impurities.

At the same time, Coriolis mass flow meters can directly measure mass flow rate, density, and temperature, and support signal output for all three parameters.

- Oval Gear Flow Meter

The oval gear flow meter is the most widely used mechanical flow meter. During measurement, the measured medium must not contain impurities, so a filter should be installed at the front of the flow meter.

It can measure media with viscosities up to 2000 mPa·s. High-temperature versions can be customized up to 400°C.

It also supports customization with cast iron, cast steel, and stainless steel materials.

- Target Flow Meter

The target flow meter uses a target plate to measure flow velocity, replacing components such as rotors and gears. Therefore, the target flow meter has higher compatibility with different media.

Wear-resistant materials and Teflon anti-stick coatings can be used, allowing for smooth measurement of various media, including those with particles, flocculants, and high viscosity.

The target flow meter also supports high-temperature and high-pressure customization, from -40°C to 450°C, with pressures up to 42 MPa.

- GF Gear Flow Meter

The GF gear flow meter is more suitable for measuring very low flow rates. It can also perfectly measure viscous media, with viscosities up to 400,000 cp.

Low flow rates can be measured down to 0.1 L/H. High pressure up to 40 MPa and high and low temperatures from -200℃ to +200℃ are all customizable.

- High Viscosity Flow Meters

- Rotary Flow Meter – Strong Adaptability to Viscosity Changes-DN20~DN100

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

Level Measurement of High-Viscosity Fluids

Level measurement of high-viscosity media (such as syrups, resins, and molten plastics) and easily crystallizing media (such as sulfate solutions and concentrated dairy products) has long presented technical challenges. Traditional level instruments often suffer from signal drift, slow response, and frequent maintenance due to interference from the media characteristics. Sino-Inst recommends non-contact radar level transmitters and contact-type dual-flange differential pressure level transmitters.

The 80G radar level transmitter emits high-frequency electromagnetic waves (microwave/millimeter wave) and calculates the liquid level by analyzing the time difference of the reflected waves. The non-contact design completely avoids media adhesion problems and is suitable for easily crystallizing and highly corrosive media. Frequency-modulated continuous wave (FMCW) technology offers strong anti-interference capabilities and can penetrate steam and foam layers. It can also be customized for ultra-large measurement ranges of 0-150m.

The dual-flange differential pressure level transmitter calculates the liquid level by measuring the pressure difference between the positive and negative pressure side diaphragms. The flanges are in direct contact with the medium, eliminating the need for pressure pipes and preventing crystallization blockage. Diaphragm materials can be selected from Hastelloy and tantalum for strong corrosion resistance.

Temperature Measurement of High-Viscosity Fluids

There are many types of temperature sensors with diverse structural forms. The appropriate temperature sensor for high-viscosity fluids can be selected based on the characteristics of the medium and the requirements of the measurement conditions.

First, the temperature range needs to be considered. For example, the typical measurement range of a PT100 is -200℃ to +850℃, while a K-type thermocouple can measure temperatures from -200℃ to +1250℃.

Then, the form of the temperature sensor probe needs to be considered. Examples include flat-type, thick-needle probe type, and spiral probe type. For instance, the thick-needle probe type uses a long, thin probe inserted into the viscous medium, sensing the temperature through axial heat conduction. This is suitable for high-viscosity liquids and semi-solid media (such as honey and butter).

- Industrial Resistance Temperature Detector Series Products

- Understanding RTD Sensors: Key to Measure Industrial Temperature

- Temperature Transmitter Overview | Installation and Calibration

- Industrial RTD Temperature Sensors: A Compl ete Guide

- What is a Thermocouple Sheath? Types – Materials – Selection Guide

In addition to the products and solutions for high-viscosity fluids introduced here, Sino-Inst also offers customized services to support various parameters.

-1.jpg)