High temperature and high pressure type pressure measurement is an extremely harsh measurement. Usually, the temperature is higher than 80℃, or the pressure is higher than 60MPa, which exceeds the measurement range of conventional pressure transmitters.

Sino-Inst supports providing you with customized solutions for various high temperature and high pressure measurement parameters.

Customized case

The user needs a pressure sensor to measure the pressure after the battery thermal runaway. The temperature is 600-700 degrees, and the range is about 100MPa. The frequency is preferably 1000Hz or above.

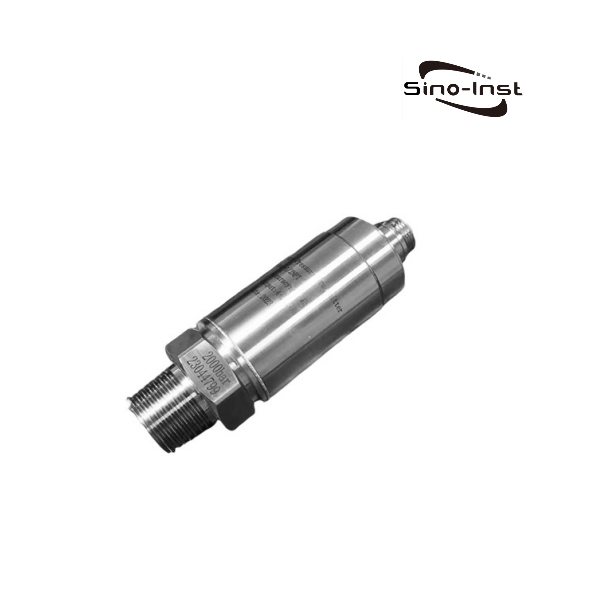

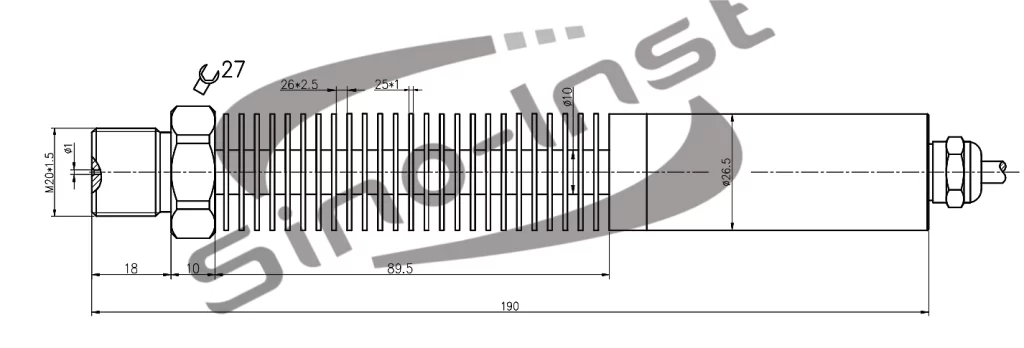

Then we provide users with the following customized products:

Technical description:

- Range: 0-100MPa gauge pressure;

- Output: 4-20mA;

- Accuracy: 0.5%FS;

- Power supply: 24VDC;

- Operating temperature range: 700℃;

- Overload capacity: 150%S;

- Long-term stability: 0.1%FS/year;

- Mounting thread: M20*1.5

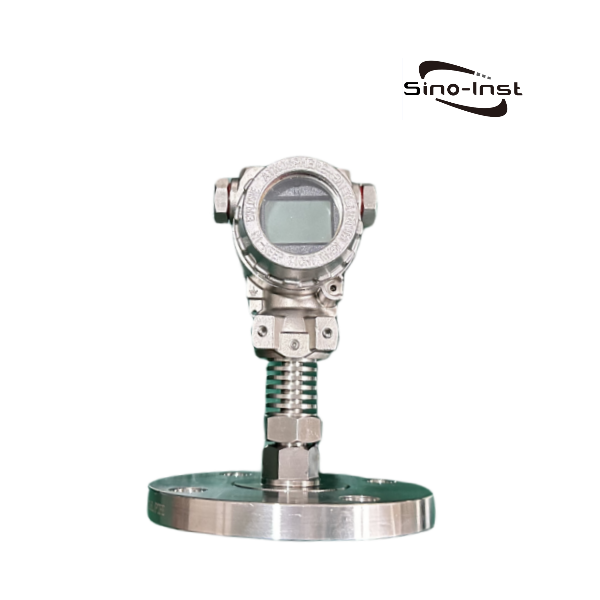

More Customized pressure transmitters

How is the pressure measured?

Pressure is one of the important parameters in the industrial production process. The transportation of fluids and changes in the physical properties of materials are all related to pressure.

At the same time, pressure is also a safety indicator in the production design process. Any equipment can only withstand the pressure specified by the design. If the pressure exceeds the allowable range, the equipment may be damaged. Even explosion accidents may occur, resulting in huge losses.

Therefore, pressure measurement is very important in the fields of automobiles, manufacturing, aviation, biomedicine, and even in the fields of air conditioning and electronic equipment that are closely related to our lives.

Pressure refers to the force acting vertically on a unit area. In pressure measurement, there are often absolute pressure, gauge pressure, differential pressure, negative pressure or vacuum. The legal unit of pressure is Pa (Pa), and the commonly used units for expressing pressure include kilopascals (KPa), megapascals (MPa), millimeters of water column (mmH2O), millimeters of mercury column (mmHg), bar (Bar), pounds per square inch (psi), etc.

There are 4 main methods for pressure measurement: balance method (liquid column method), elastic method (mechanical method), piston method, and electrical method (digital method). Common electrical pressure gauges include pressure switches and pressure sensors.

Pressure sensors are well known to everyone. Because they output electrical quantity, it is convenient for signal transmission, especially convenient to connect with computers to form an automatic data acquisition system, so they have been widely used, which has greatly promoted the development of test technology.

There are four main methods of pressure measurement: balance method (liquid column method), elastic method (mechanical method), piston method, and electrical method (digital method). Common electrical pressure gauges include pressure switches, pressure sensors, etc.

Pressure sensors are well known to everyone. Because they output electrical quantity, it is convenient for signal transmission, especially convenient to connect with computers to form an automatic data acquisition system, so they have been widely used, which has greatly promoted the development of test technology.

What are the types of pressure measurement?

There are three main types of pressure measurements in our industrial process pressure measurement:

- Absolute pressure measurement

- Definition: Absolute pressure sensors measure pressure relative to a perfect vacuum (zero pressure).

- How it works: These sensors typically use a sealed chamber that is referenced to a vacuum. The pressure of the medium being measured is compared to the vacuum, providing an absolute pressure reading.

- Applications: Used for barometric pressure readings, altimeters, and applications that require accurate atmospheric pressure measurements.

- Gauge pressure measurement

- Definition: Gauge pressure sensors measure pressure relative to the ambient atmospheric pressure.

- How it works: The sensor measures the difference between the pressure in the system and the ambient air pressure. If the system pressure is above atmospheric pressure, the gauge pressure is positive; if it is lower, it is negative.

- Applications: Commonly used in tire pressure gauges, blood pressure gauges, and fluid power systems.

- Differential pressure measurement

- Definition: Differential pressure sensors measure the difference in pressure between two points in a system.

- How it works: These sensors have two input ports, each connected to a different point in the system. The sensor measures the difference in pressure between these two points, which is critical for systems with large pressure drops.

- Applications: Used in HVAC systems, flow measurement, filter monitoring, and level measurement.

More Pressure Measurement Solutions

- Pressure Transducer Troubleshooting: Expert Insights & Tips

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- Steam Pressure Sensor/transducer for Industrial Steam Measurement

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

Accurate monitoring and control of pressure changes requires comprehensive consideration of multiple factors such as the type, accuracy and measurement technology of the pressure sensor. By rationally selecting and applying pressure sensors, accurate monitoring and control of pressure can be effectively achieved.

With the continuous emergence of new materials and new processes, the performance of pressure sensors will be further improved. Sino-Inst produces a full range of process pressure transmitters. Supports customization of various parameters. Including high temperature, extremely low temperature, ultra-high pressure, high precision, etc.

If you need customized pressure measurement, or have related technical questions, please feel free to contact our sales engineers!

-1.jpg)