What is clamp on ultrasonic flow meter? Ultrasonic clamp on flow meters is a non-contact flow measurement device. By installing a pair of sensors on the outside of the pipe, the flow of liquid fluid is measured using the transmission and reception of ultrasonic waves.

There are two types of non-contact ultrasonic flowmeter technology, including Doppler technology and transit time technology.

Ultrasonic clamp on flow meters have become increasingly popular due to their non-invasive nature, quick installation, and ease of use.

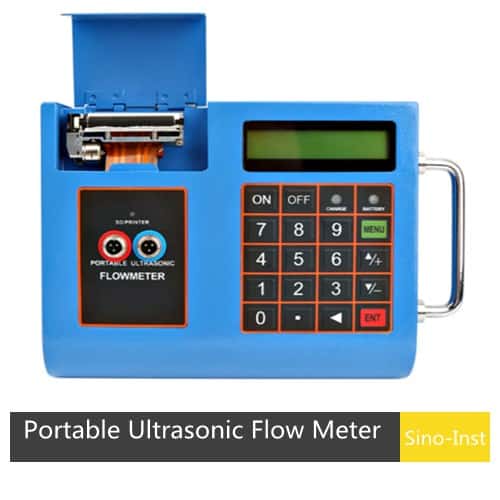

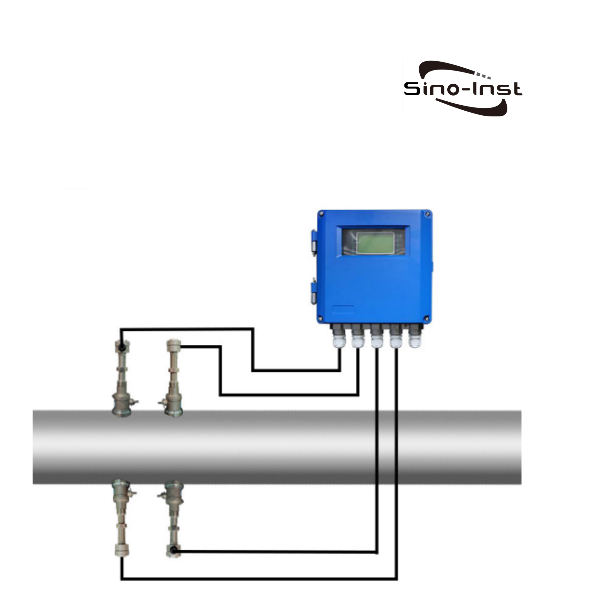

Sino-Inst supplies various types of Ultrasonic Clamp on Flow Meters for liquid. Including wall-mounted hosts, handheld portable hosts. You can also choose a Doppler flow meter or a heat meter.

Featured Ultrasonic Clamp on Flow Meters

Working Principle of Ultrasonic Clamp-on Flow Meters

Sino-Inst supplies mainly transit-time ultrasonic flowmeters. Here we briefly introduce the time difference method and Doppler ultrasonic flowmeter.

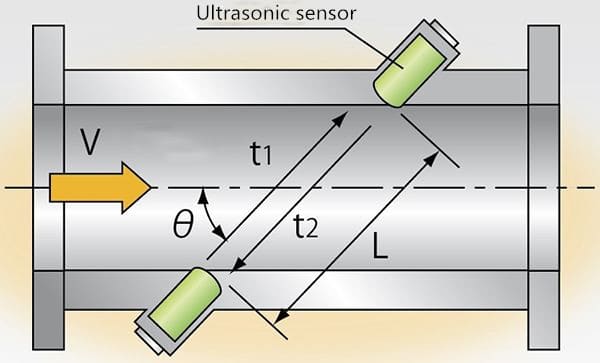

Time of Flight (ToF) Method

The most common method used in ultrasonic clamp-on flow meters is the Time of Flight (ToF) technique. This method involves transmitting ultrasonic signals from one transducer to another, mounted on opposite sides of the pipe. The time difference between the transmitted and received signals are used to calculate the flow rate.

Doppler Method

The Doppler method is another technique used in ultrasonic clamp-on flow meters. It relies on the Doppler effect, where the frequency of the transmitted ultrasonic signal changes as it reflects off particles or bubbles within the fluid. This frequency shift is used to determine the flow rate.

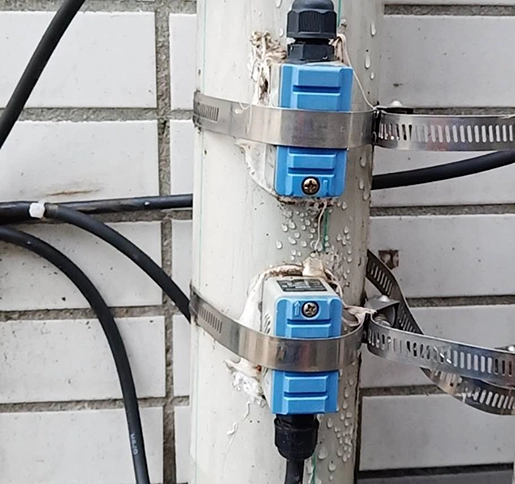

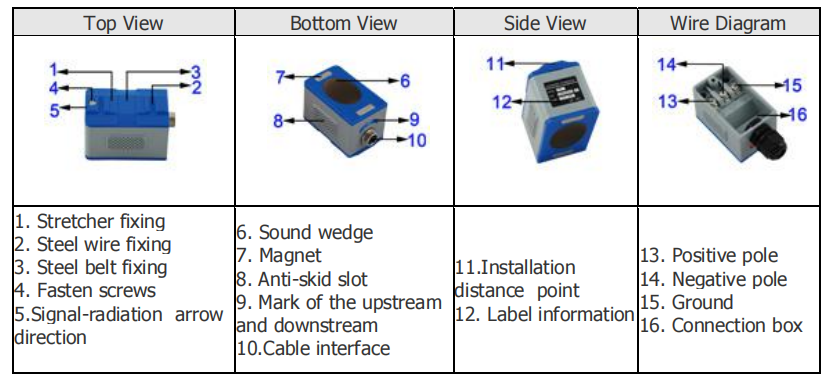

Details About clamp on flow sensor

- The sensor can be fixed on a steel or iron pipe with a magnet

- The ground terminal can enhance anti-interference

- The sensor cover can be fixed in a variety of ways, including steel belt, stretcher, and steel wire

- The sensor is marked with the direction of ultrasonic signal radiation

- The sensor is sealed with glue to reach IP68

- There are high-temperature sensors and standard sensors, including large, medium and small.

Standard temperature range: -30~90℃; high temperature range: -30~160℃ - Depending on the installation conditions, the sensor can be divided into portable and fixed types.

Benefits of clamp on ultrasonic flow meter: A Quick & Easy Solution for Flow Measurement

Advantages of clamp-on ultrasonic flowmeter:

- Non-contact measurement. Will not interfere with fluid flow. Nor will it be corroded or abraded by fluids.

- It can be used for flow measurement of media with large diameter, high flow rate, high viscosity, strong corrosiveness, non-conductivity and other media.

- High measurement accuracy, good stability, and wide range ratio, which can reach 100:1.

- With reverse flow measurement function. Two ultrasonic flow meters can be installed at both ends of the pipeline to achieve accurate measurement of bidirectional flow.

- No pressure loss. Since there is no need to insert anything into the pipe, there is no pressure loss in the clamp-on ultrasonic flowmeter.

- Has a variety of output interfaces, including RS485, 4-20mA, etc. Can be easily connected with host computer or other equipment.

- Thermal energy measurement: Clamp-on ultrasonic flow meters can be used in the field of thermal energy measurement to accurately measure the flow of heat transfer media such as hot water and steam to help energy conservation and metering management.

- The external clamp sensor can cover more pipe diameters. Achieve maximum flow measurement of pipes of different sizes at the lowest cost.

clamp on ultrasonic heat meter

Clamp on Ultrasonic heat meters can measure the temperature and heat flow of the medium. Ultrasonic heat meters need to be used with temperature sensors. Ultrasonic flow meters simply measure the flow of the medium.

The working principle of ultrasonic heat meters is also the ultrasonic time difference method. A pair of temperature sensors are installed on the up-going pipe and down-going pipe through which the heat-carrying fluid passes. The flow meter is installed on the fluid inlet or return pipe (the final measurement results are different depending on the location of the flow meter installation). The flow meter sends out a pulse signal proportional to the flow rate, and a pair of temperature sensors give out an analog signal indicating the temperature. The integrator collects signals from the flow and temperature sensors. The heat obtained by the heat exchange system is calculated using the integrator formula.

Frequently asked questions

More Flow Measurment Solutions

Checklist: Vortex Flow Meter Advantages and Disadvantages

Industry Application: Paper Mill Slurry Wastewater Treatment System

Oval Gear Flow Meters with Better Price | Advantages and Disadvantages

Brewery Flow Meters for Beer and Wine | Electromagnetic and More

What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

Target Flow Meter Advantages And Disadvantages and Featured Applications

In conclusion, ultrasonic clamp on flow meters offer a quick and easy solution for flow measurement in various industries and applications. With their non-invasive design, accurate measurements, and minimal maintenance requirements, they can significantly improve process efficiency and reduce operating costs.

As an experienced manufacturer and supplier, Sino-Inst is dedicated to providing customizable, high-quality ultrasonic clamp on flow meters that meet your unique requirements. Contact us today to discuss your flow measurement needs and discover how our ultrasonic clamp on flow meters can help optimize your processes.

-1.jpg)