Industrial smart pressure transmitters are microprocessor-based high-performance transmitters. With flexible pressure calibration function. Instrument equipment commonly used in industrial process control can convert fluid or gas pressure into standard analog signals (such as 4-20mA) or digital signals (HART, RS485) and output them to the control system.

What is a smart pressure transmitter?

Smart pressure transmitter is an upgraded version of the pressure transmitter for process applications. Smart pressure transmitters integrate pressure sensing, amplification, linearization, temperature compensation, digital processing and communication.

It realizes the analysis, processing and output of pressure signals through internal intelligent algorithms. And supports a variety of standard signal output methods, such as 4-20mA, 0-5V, etc. Or digital signals, HART, Modbus RS485, etc.

Smart pressure transmitters are capable of performing pressure monitoring and control applications. Therefore making it an integral part of fluid power systems.

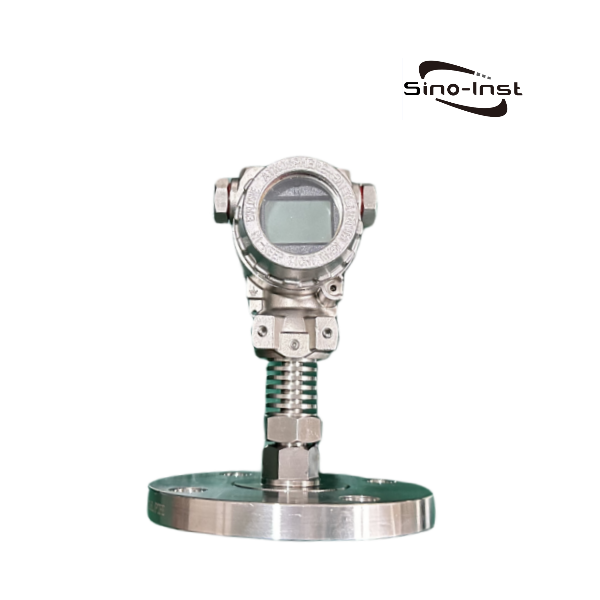

Featured Industrial Smart Pressure Transmitters

Featured Smart Differential Pressure Transmitters

Advantages of Intelligent Pressure Transmitters

- High-precision measurement:

- Smart pressure transmitters typically have high-precision pressure measurement capabilities. It can usually achieve an accuracy of 0.1%~0.2%, meeting the requirements of industrial automation control.

- Digital signal processing:

- These transmitters integrate digital signal processing technology, which can digitally process the analog signals collected by the sensors, thus improving the stability and anti-interference ability of the signals.

- Temperature compensation:

- Smart pressure transmitters often have built-in temperature sensors. The ambient temperature can be monitored in real time. And automatically compensates the pressure value according to temperature changes to improve the accuracy of measurement.

- Good anti-interference ability:

- Built-in filter, linear error compensation, calibration and automatic calibration functions effectively improve the anti-interference ability of the instrument.

- Multiple output signals:

- These transmitters can provide a variety of output signal types. Such as analog signals (such as 4-20mA, 0-10V) and digital signals (such as MODBUS, HART protocol) to adapt to different control systems and data acquisition equipment.

- Remote monitoring and configuration:

- By supporting communication protocols, smart pressure transmitters can achieve remote monitoring and configuration. Thereby reducing manual intervention and improving operation and maintenance efficiency.

- Programmable functions:

- Some smart pressure transmitters have programmable functions, allowing users to set and adjust parameters according to actual needs.

Smart Pressure Transmitters Applications

Intelligent pressure transmitters are widely used in chemical, electric power, metallurgy, petroleum, water treatment and other industries. They are important measuring instruments for process control and safety assurance.

The main applications include:

- Pressure detection and control: such as pipeline pressure monitoring, gas meters, steam pressure control, etc.;

- Liquid level measurement: Convert the liquid level height into a standard signal through a pressure transmitter to achieve online measurement and control of the liquid level.

- Flow measurement: Combining different types of flow sensors, flow measurement and control of liquids and gases can be achieved.

More Pressure Measurement Cases:

What is the difference between smart transmitter and normal transmitter?

Here, we take a pressure transmitter as an example. By analyzing the differences between conventional pressure transmitters and smart pressure transmitters, you will understand the differences between smart transmitter and normal transmitter.

Conventional pressure transmitter: converts the physical pressure (gas, liquid, etc.) parameters sensed by the load cell sensor into standard electrical signals (such as 4~20mADC, etc.) to supply indicating alarms, recorders, regulators, etc. Secondary instruments measure, indicate and regulate processes.

The popular explanation is to convert pressure into electrical signals and output them to places for indication and adjustment.

Intelligent pressure transmitter: The intelligent pressure transmitter has the same working properties as a conventional pressure transmitter. It’s just that the “smart” in the intelligent pressure transmitter refers to the self-processing system chip inside it. What is the specific performance?

Let’s compare the differences between the two in layman’s terms:

From the perspective of signal conversion:

Conventional pressure transmitters convert other signals into analog signals and output them to the device.

The signal format of the intelligent pressure transmitter is analog and digital compatible. The analog signal and the digital signal share a channel and use a pressure transmitter for protocol communication.

The so-called communication is simply that it can monitor the scene through the chip in the intelligent pressure transmitter or connect with the host computer to form an on-site monitoring system.

And what are the benefits of this?

You can get information about on-site equipment without going to the site. And the configuration information of the on-site pressure transmitter can be transmitted and saved directly to the remote computer. The benefits of on-site maintenance and monitoring have been significantly improved.

More Pressure Measurement Solutions

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

As an indispensable and important equipment in the industrial field, pressure transmitters play a key role in ensuring production safety and stability. Intelligent pressure transmitters have become an important part of modern industrial intelligence due to their precise measurement capabilities and wide range of applications.

Sino-Inst manufactures and supplies various types of smart pressure transmitters. You can choose to configure 4-20mA, 0-10V, HART, RS485 and other signal outputs. We support OEM and provide special discounts for bulk purchases.

If you need to configure an intelligent pressure transmitter or have related technical questions, please contact Sino-Inst sales engineers!

-1.jpg)