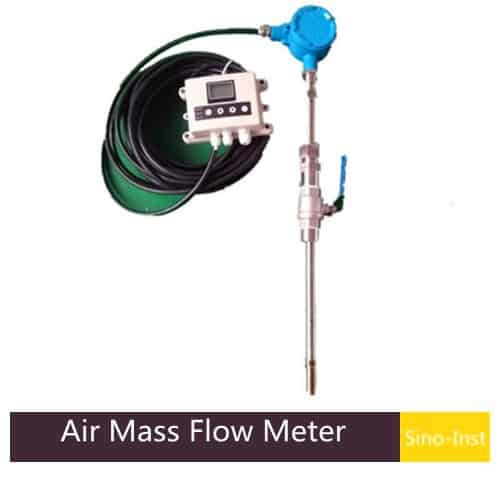

The Thermal Air Mass Flow Meter directly measures dry air flow using the principle of heat diffusion. It is unaffected by changes in parameters such as temperature, pressure, and density, offering higher measurement accuracy and stability.

The Thermal Air Mass Flow Meter is ideal for monitoring air networks, measuring consumption, detecting leaks, and reducing costs. In addition to compressed air supply, it can also be used with non-corrosive gases such as oxygen, nitrogen, and carbon dioxide.

| Diameter | DN10~DN4000mm |

| Accuracy | ±1.5% |

| Temp. range | -40~200℃ |

| Pressure | Max 4MPa |

| Flow rate | 0.5-100m/s |

| Protection | IP67 (sensor part) |

Features

- Temperature and pressure compensation is not necessary, measurement process is simple and accurate.

- Could measure mass flow or standard volume flow rate of air.

- Range ratio 100:1, could measure gas flow from 100Nm/s to 0.5Nm/s and be used for gas leak detection.

- Good vibration resistance, long service life. No moving parts or pressure detecting parts, accuracy will not be affected by vibration.

- Easy installation and maintenance.

- Adopt overall digitizing circuit measurement to ensure high accuracy.

- Flow meter is with RS485 communication, could be part of automation and integration of your facilities.

Specifications

| Medium | All gases (except acetylene) | |||||

| Pipe diameter | DN10-80 (Flange type) | DN100-4000 (Insert type) | ||||

| Flow rate | 0.5-100Nm/s | |||||

| Accuracy | ±1% | |||||

| Operating temp. | Sensor | Default type: -10~+200℃High temp. type: -10~350℃ | ||||

| Transmitter | -20~+45℃ | |||||

| Operating pressure | Medium pressure≤10MPa | Medium pressure≤2.5MPa | ||||

| Power supply | Compact type | DC24V or AC220V≤18W | ||||

| Remote type | AC220V≤19W | |||||

| Response time | 1s | |||||

| Output | 4-20mA | Optical isolation, max. load 500Ω | ||||

| RS485 | Optical isolation | |||||

| HART | ||||||

| Pipe material | Carbon steel, stainless steel, plastic, etc. | |||||

| Display | Compact type: 4 lines LCD display | |||||

| Display content | Mass flow, standard volume flow, accumulated flow, time, accumulated time, medium temp., standard flow, etc. | |||||

| Ingress protection | IP67 (sensor part) | |||||

| Sensor material | Stainless steel | Stainless / carbon steel | ||||

About Air in Industry

Air and compressed air are widely used in industrial production. As a clean, efficient, and readily available energy source, they play a vital role in a wide range of fields.

Driving Mechanical Equipment:

Air is widely used to drive various pneumatic tools, pneumatic clamps, cylinders, and other equipment. These devices play a critical role in industrial production lines, such as assembly and packaging lines, where the use of compressed air significantly improves production efficiency.

Pneumatic Control Systems:

Air is also used to control pneumatic control systems, such as the opening and closing of pneumatic valves and the operation of pneumatic motors. This control method offers advantages such as fast response and high control accuracy, making it widely used in industrial scenarios requiring precise control.

Machinery and Equipment Cleaning:

During the manufacturing process, air compressors provide high-speed compressed air to purge and clean dust, dirt, and other impurities from the surfaces of machinery, equipment, and parts, thereby improving product quality and production efficiency.

Pipeline System Purging:

During the installation and maintenance of piping systems, compressed air is also used to purge the interior of pipes to remove residue and impurities, ensuring unobstructed operation.

Surface Spraying:

Compressed air is used in spraying operations in industries such as construction and automotive. Compressed air atomizes the paint and applies it to the workpiece surface, creating a uniform coating that improves the product’s appearance and corrosion resistance.

Sandblasting:

In metal surface treatment, compressed air is mixed with sand particles to form a high-speed jet stream, which is used to remove rust, scale, and other contaminants from the metal surface, preparing it for subsequent painting or machining.

Chemical Reactions:

In the chemical industry, compressed air is also used in certain chemical reactions, such as synthesis and polymerization. Compressed air provides the necessary pressure and oxygen environment to facilitate the reaction.

In addition to these applications, you can also see air compressor equipment in many aspects of our lives.

Air Flow Measurement

In addition to thermal mass air flow meters, we also offer other types of air flow meters. These include vortex flowmeters, Precession vortex flowmeters, differential pressure flowmeters, and metal rotor flowmeters.

Vortex Flowmeter

Operating Principle: A vortex flowmeter measures flow by using the vortices formed by the fluid behind an obstruction. The frequency of the vortices is proportional to the flow velocity, enabling accurate flow measurement.

Advantages:

- High accuracy, suitable for precise measurement of compressed air flow.

- Real-time monitoring facilitates immediate detection of flow rate changes.

- A wide range of applications makes it a common instrument for measuring compressed air flow.

Disadvantages:

Sensitive to impurities and pulsation in the fluid, which may affect measurement accuracy.

Precession vortex flowmeter

Operating Principle: A swirl flowmeter measures flow by using the vortices formed by the fluid behind a vortex generator. The frequency of the vortices is proportional to the flow velocity, enabling accurate flow measurement.

Advantages:

- Suitable for low flow rates and small orifices.

- Simple structure and easy maintenance.

Disadvantages:

- Sensitive to impurities and pulsation in the fluid, which may affect measurement accuracy.

- Relatively limited scope of application.

Differential Pressure Flowmeter

Working Principle: A differential pressure flowmeter calculates flow rate by measuring the pressure difference generated by the fluid flowing in a pipe. Common examples include Venturi tube and orifice plate flowmeters.

Advantages:

- Simple structure, easy to install and maintain.

- Relatively low cost, suitable for projects with limited budgets.

Disadvantages:

Measurement accuracy is significantly affected by fluid conditions (such as Reynolds number and fluid viscosity), and additional calibration may be required.

There are many types of flowmeters that can measure air, and we can select the most suitable one based on the actual measurement parameters.

How to Choose an Air Mass Flow Meter?

Based on our years of experience in flow measurement, we recommend considering the following factors when selecting an air flow meter:

- Flow Range: The pipeline’s operating flow rate or standard flow rate.

- Fluid Characteristics: Consider factors such as gas composition, humidity, pressure, and temperature to select the appropriate flowmeter. Measurement Accuracy: Select the appropriate accuracy level based on your measurement requirements.

- Installation Conditions: Pipe diameter, flowmeter installation location, and pipe diameter can affect performance and require advance planning.

- Maintenance Requirements: Some flowmeters require regular calibration and maintenance, so ease of maintenance should be considered when selecting.

- Cost Budget: Select the appropriate flowmeter type based on your budget.

Order Guide

In addition to regular products, we support customization

| SI-3502 | Thermal mass flow meter |

| Sensor type | C Retrench pattern insert type |

| D Online pluggable type | |

| E Flange pipe type | |

| F Thread pipe type | |

| G Clamp on type | |

| Pipe diameter | C Round pipe: DN15~DN6000 |

| S Square pipe: 25*25mm~2000*2000mm | |

| Housing material | A SUS304 |

| B SUS316 | |

| C Other material | |

| Pressure | S 1.6MPa |

| M 2.5MPa | |

| T 4.0MPa | |

| Temp. | I 10~200℃ |

| II 10~400℃ | |

| Output | 1 4-20mA |

| 2 RS485 | |

| 3 PULSE | |

| 4 Relay contact | |

| 5 HART | |

| Power | DC 24VDC |

| AC 220VAC | |

| Display | J Integrated display |

| S Split display |

More Flow Measurement Solutions

The Air Mass Flow Meter directly measures fluid mass flow, eliminating the need for cumbersome volume conversions. By monitoring heat loss, it accurately determines the fluid’s mass flow rate. Therefore, it is the preferred choice for dry air flow monitoring in most industrial applications.

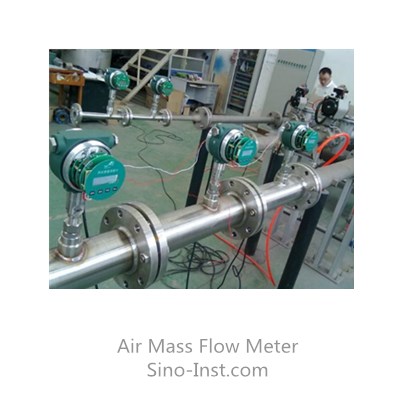

Sino-Inst’s Air Mass Flow Meter offers stable measurement performance. It is available in flange, insert, and split configurations. If you require air flow measurement, please feel free to contact us.

-1.jpg)