Electromagnetic flow meters measure the volumetric flow of conductive liquids in closed pipes. Electromagnetic water flow meters are the preferred process water flow meter. Most industrial water supply pipes (1-inch, 3-inch, etc.) require online flow measurement. They display instantaneous flow in real time, provide totalizer flow, and support pulse, 4-20mA, and RS485 signal outputs.

Electromagnetic digital flow meters are suitable for: domestic water, industrial water, raw water, ground water, urban sewage, industrial wastewater, pulp slurry, and more.

| Diameter | DN6~DN3000mm |

| Accuracy | ±0.5% |

| Flow rate | 0.3~15m/s |

| Electrode | 316L (Suitable for domestic water, industrial water, raw water, underground water, sewage, etc.; not applicable to acid and alkali salt) |

| Lining material | Chloroprene rubber(CR), polyurethane rubber(PU), PTFE(F4) |

Digital Electromagnetic Water Flow Meter Features

Electromagnetic Water Flow Meter Specifications

| Main power | AC220V 50HZ / DC24V | |

| Power consumption | < 15W (And set with sensor supporting power consumption ) | |

| Display and push buttons | Can display the instantaneous flow, total flow and percentage of flow as well as alarm display, four thin-film touch nubs, which is used to data set. | |

| Accumulator | Forward total quantity, reverse total quantity | |

| Output signal | Analog output | Bi-direction with two ways, Isolation 0-10mA/4-20mA |

| Load resistor: 0-10mA; 0-1.5KΩ; 4-20mA; 0-750Ω | ||

| Frequency output | Forward & reverse flow output with frequency range set between 1-5000Hz.The external voltage must be lower than 35V and the max output and the max output current is 50mA when the transistor is turned on | |

| Alarm output | Two outputs from the collectors of photoelectric isolate transistors are for alarm signals. The external voltage must be lower than 35V and the max output current is 250mA when the transistor is turned on. Alarm status: Activates when the measured pipes are empty, the excitation circuits are broken or the volume of flow rate exceeds the value designed limits. | |

| Pulse output | For pulse output in forward and reverse flow measurement, upper frequency of pulse output can be up to 5000 CP/S relevant value of pulse is from 0.0001 to 1.0 M3/P. The width of pulse can be set to 20ms or squired wave from automatically. The collector of transistor with photoelectric is open circuited. The external voltage must be lower than 35 V and maximum output current is 250mA when the transistor is turned on. | |

| Accuracy | ±0.5% of the value displayed, ±0.3% or ±0.2% optional. | |

| Damping time constant | Continuous variable from 0-100 s (90%)can be selected by group | |

| Communication | RS232 ,RS485 or HART Communication are optional,with lighting resistance | |

| Power failure | An anti-failure clock is designed in the flow meter which can save the power failure records for 16 times (10 years) | |

| Nominal diameter | DN6~DN3000mm | |

| Nominal Pressure | 0.6~4.0MPa | |

| Main power | AC220V 50Hz /DC24V/3.6V | |

| Accuracy | ±0.5%, ±0.3% or ±0.2% are optional | |

| Output signal | Analog output, Frequency output, Alarm output, Pulse output | |

| Liner material | Neoprene, Urethane Rubber, Polysilicone Rubber, PTFE, F46, PFA | |

| Electrode Type | General type, scraper type and replaceable type | |

| Electrode material | SUS316, Hastelloy B, Hastelloy C, Titanium, Tantalum, Platinum-iridium alloy, Stainless steelcovered with tungsten carbide | |

| Medium temperature | -20ºC~+70ºC | |

| Ambient Temperature | -25ºC ~ +60ºC | |

| Ambient Humidity | 5~100%RH(relative humidity) | |

| Medium Electrical conductivity | ≥20us/cm | |

| Measuring Range | 1500:1,flow rate <15m/s | |

| Structure type | Integral type, remote type, submersible type, ex-proof type <15m/s | |

| Protection Class | IP65, IP67, IP68(optional) | |

Electromagnetic Water Flow Meter Applications

Electromagnetic flowmeters are widely used in the water industry, especially in sewage treatment and other fields. As long as the conductivity of the medium is greater than 5μs/cm.

If there are many liquids with suspended particles, Electromagnetic water flow mete is also suitable. For example, sewage, wastewater, chemicals, mud, etc.

SI-3101 Magnetic flow meter is suitable for water flow measurement, like:

Domestic water, industrial water, raw water, ground water, urban sewage, industrial wastewater, the processed neutral pulp, pulp slurry, etc.

Order Guide

| SI-3101- | Note | ||||||||||||

| Diameter | DNXX | DN6~DN3000(mm) | |||||||||||

| Structure | F | Remote type (standard with 10m cable) | |||||||||||

| Y | Compact type | ||||||||||||

| Electrode | S | 316L | |||||||||||

| T | Titanium(Ti) | ||||||||||||

| D | Tantalum(Ta) | ||||||||||||

| C | Hastalloy C(HC) | ||||||||||||

| P | Platinum iridium alloy | ||||||||||||

| Lining material | X | Chloroprene rubber (CR) Suitable for tap water, | |||||||||||

| J | Polyurethane rubber (PU) Suitable for pulp, pulp, etc liquid | ||||||||||||

| E | Polytetrafluoroethylene (PTFE) | ||||||||||||

| A | PFA | ||||||||||||

| Body material | CS | Carbon steel | |||||||||||

| S4 | SUS304 | ||||||||||||

| Protection class | L0 | IP65(compact type) | |||||||||||

| L1 | IP67(remote type) | ||||||||||||

| L2 | IP68(remote type) | ||||||||||||

| Power supply | 1 | 110~240V AC | |||||||||||

| 2 | 24V DC | ||||||||||||

| 3 | Lithium battery(no signal output) | ||||||||||||

| Signal output | N | No output | |||||||||||

| N1 | 4-20m/pulse output | ||||||||||||

| Communication | H | HART protocol | |||||||||||

| R1 | MODBUS RS485 | ||||||||||||

| G | GPRS | ||||||||||||

| With grounding ring | 0 | Without grounding ring | |||||||||||

| 1 | With grounding ring | ||||||||||||

| Nominal pressure | D1 | DIN PN16 | |||||||||||

| D2 | DIN PN25 | ||||||||||||

| D3 | DIN PN40 | ||||||||||||

| D4 | DIN PN63 | ||||||||||||

| J1 | JIS 10K | ||||||||||||

| J2 | JIS 20K | ||||||||||||

| J3 | JIS 40K | ||||||||||||

| A1 | ANSI Class150 | ||||||||||||

| A2 | ANSI Class300 | ||||||||||||

| A3 | ANSI Class600 | ||||||||||||

| O | Others | ||||||||||||

| Cable length | /xx | Unit: m | |||||||||||

Technical Support

Wastewater flow meter

Wastewater Flow meters are flowmeters for water and wastewater treatment. Electromagnetic flow meters are suitable for open channel and underground industrial water pipes.

Potable Water

Potable water flow meter also called Drinking water. Potable water flow meters are important for Domestic industries. Accurate flow measurement is essential to cost-conscious drinking water and potable water system.

Digital Water Flow Meter

Digital water flow meter, is the electronic flow meter, which display the flow rate of water. Different Industrial liquid, different pipe for 1 inch, 2 inch, use different flow meters

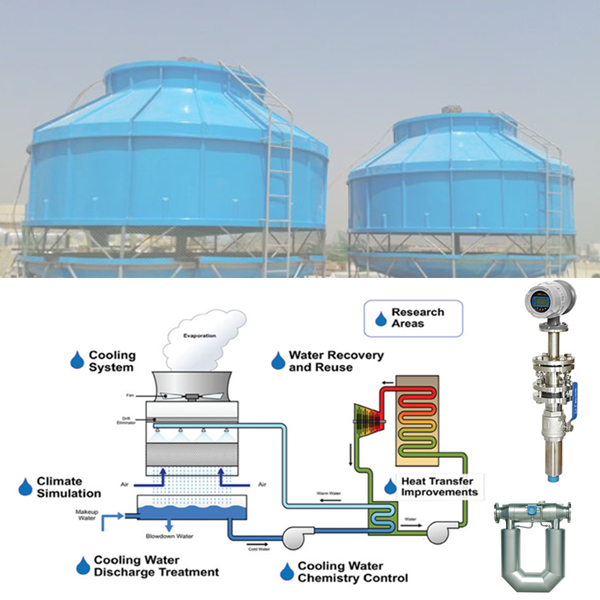

Cooling Water

The cooling water flow meter is used to measure the cooling water flow rate. Cooling water flow meters are commonly used in cooling water towers, circulation systems, pipes, tanks, and pumps.

FAQ

More Water Flow Meters

Electromagnetic water flow meters have a wide range of applications.

Large-diameter meters are commonly used in water supply and drainage projects, while small and medium-diameter meters are often used in demanding or difficult-to-measure applications. Examples include controlling blast furnace tuyere cooling water in the steel industry, measuring pulp and black liquor in the paper industry, measuring highly corrosive liquids in the chemical industry, and measuring ore slurries in the nonferrous metallurgy industry.

Small-diameter and micro-diameter electromagnetic water flow meters are often used in hygiene-critical environments such as the pharmaceutical, food, and biochemical industries.

Sino-Inst offers customizable electromagnetic water flow meters. Feel free to contact our sales engineers for customized solutions!

-1.jpg)