Radar level meter is a non-contact level meter that measures the level of liquid or solid materials. 26 GHz high frequency radar level meter, measuring up to 80 meters.

Sino-Inst’s 26 GHz radar level meters support customization. High temperature 230℃, high pressure 4.0MPa. It can be used for level measurement of corrosive liquids, steam, volatile liquids, and complex measurement conditions such as reactors or solid silos.

Features

Radar level meters use a transmission frequency of up to 26GHz. Therefore, they have the following technical advantages:

Featured 26GHz Radar Level Meter Models And Parameters

RD901

- Application: Various highly corrosive liquids;

- Measuring range: 10 meters;

- Process connection: thread, flange;

- Process temperature: -40~130℃;

- Process pressure: -0.1~0.3MPa;

- Accuracy: ±5mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD902

- Application: Temperature-resistant, pressure-resistant, slightly corrosive liquids;

- Measuring range: 30 meters;

- Process connection: thread, flange;

- Process temperature: -40~130℃ (standard type) / -40~230℃ (high temperature type);

- Process pressure: -0.1~4.0MPa;

- Accuracy: ±3mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD902T

- Application: Corrosive liquids, steam, volatile liquids;

- Measuring range: 20 meters;

- Process connection: flange;

- Medium temperature: -40~130℃ (standard type) / -40~230℃ (high temperature type);

- Process pressure: -0.1~2.0MPa;

- Accuracy: ±3mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD902S

- Application: Corrosive liquids, steam, volatile liquids;

- Measuring range: 15 meters;

- Process connection: flange;

- Medium temperature: -40~130℃ (standard type) / -40~230℃ (high temperature type);

- Process pressure: -0.1~2.0MPa;

- Accuracy: ±3mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD903

- Application: Solid materials, process containers or situations where strong dust is prone to crystallization and condensation;

- Measuring range: 70 meters;

- Process connection: universal flange;

- Process temperature: -40~130℃ (standard type) / -40~230℃ (high temperature type);

- Process pressure: -0.1~4.0MPa (flat flange); -0.1~0.3MPa (universal flange);

- Accuracy: ±15mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD904

- Application: Solid materials, process containers or places where strong dust is prone to crystallization and condensation;

- Measuring range: 80 meters;

- Process connection: threaded, universal flange;

- Process temperature: -40~130℃ (standard type) / -40~230℃ (high temperature type);

- Process pressure: -0.1~0.3MPa;

- Accuracy: ±15mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD905

- Application: Solid particles, dust;

- Measuring range: 30 meters;

- Process connection: thread, flange;

- Process temperature: -40~130℃ (standard type) / -40~230℃ (high temperature type);

- Process pressure: -0.1~4.0MPa (flat flange); -0.1~0.3MPa (universal flange);

- Accuracy: ±15mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

RD905S

- Application: For the measurement of solids;

- Measuring range: 0~10 m;

- Process connection: flange / dragon door frame;

- Process temperature: -40~80℃;

- Process pressure: -0.1~0.3MPa;

- Accuracy:±15mm;

- Level of protection: IP67;

- Frequency: 26GHz;

- Field display: The four-digit LCD is programmable;

- Power supply: two-wire system (DC24V)/ Four-line system (D C 24 V/AC220V);

- Explosion-proof grade: Exia ⅡC T6 Ga / Exd ⅡC T6 Gb;

- Case: aluminum single chamber / aluminum double chamber / plastic single chamber / stainless steel single chamber;

- Signal Output: 4…20mA / HART (two wire / 4 wire)/ Mod bus-RS485;

RD906

- Application: Hygienic liquid storage containers, highly corrosive containers;

- Measuring range: 20 meters;

- Process connection: flange;

- Process temperature: -40~80℃ (standard type) / -40~200℃ (pressure and high temperature resistance type);

- Process pressure: -0.1~0.3MPa / -0.1~2.5MPa (PTFE integrally filled antenna);

- Accuracy: ±3mm;

- Frequency range: 26GHz;

- Explosion-proof grade: Exia ⅡC T6 Ga/ Exd IIC T6 Gb;

- Protection level: IP67;

- On-site display: four-digit LCD programmable;

- Power supply: two-wire system (DC24V)/four-wire system (DC24V/AC220V);

- Housing: aluminum single cavity / aluminum double cavity / plastic / stainless steel single cavity;

- Signal output: 4…20mA /HART (two wires / four wires); RS485 /Modbus;

Radar Level Meter working principle

Radar Level Meter antennas emit narrow microwave pulses. After being transmitted downward through the antenna, the microwave is reflected back after contacting the surface of the medium being measured. It is received again by the antenna system and transmitted to the electronic circuit part for automatic conversion into a level signal.

Because microwaves propagate so fast, the time it takes for an electromagnetic wave to reach the target and be reflected back to the receiver is almost instantaneous.

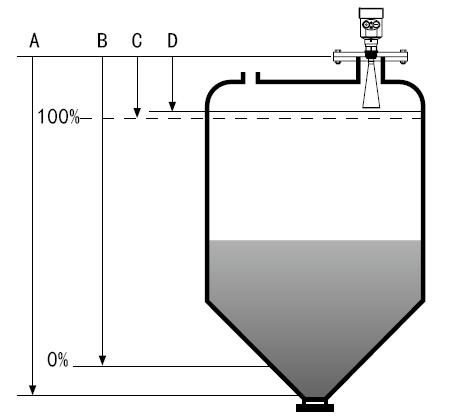

A range setting

B low adjustment

C high adjustment

D blind zone range

The reference surface for measurement is: the bottom surface of the thread or the sealing surface of the flange

Note: When using Radar Level Meter, be sure to ensure that the highest material level cannot enter the measurement blind zone (area shown as D in the picture).

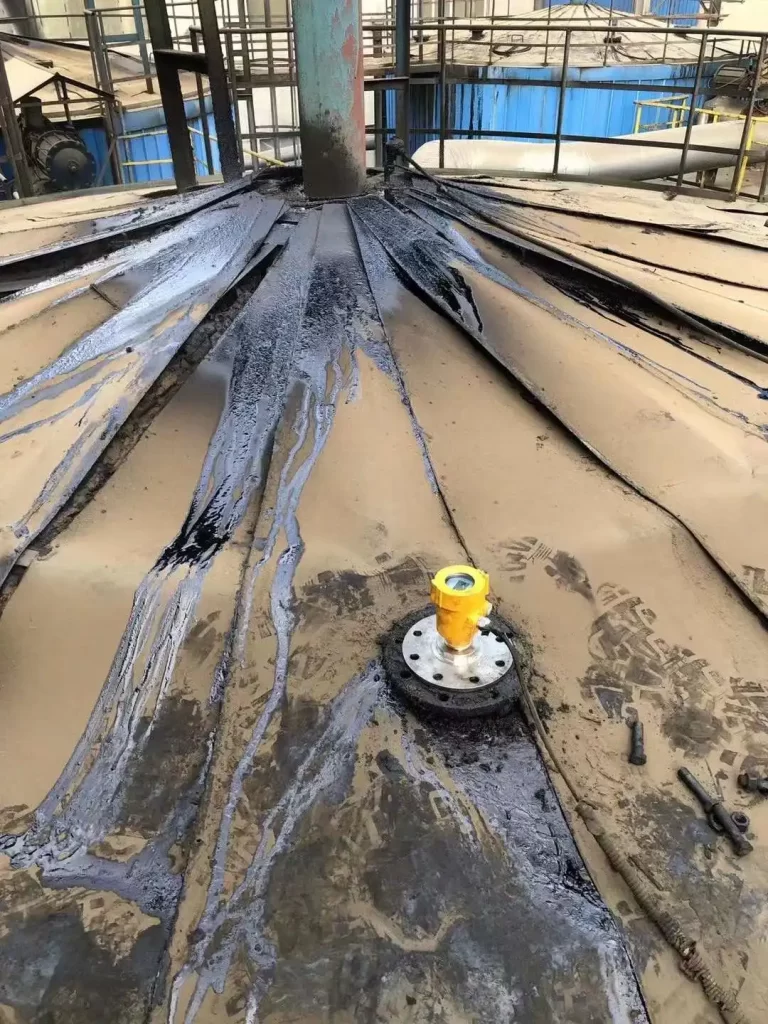

Radar Level Meter’s application industry

1. Application of radar level meter in petrochemical industry

- In the petrochemical industry, radar level meters are mainly used for:

- Crude oil, hydrogen tincture, waste oil, sludge, and sewage from oil production plants;

- Settlement tanks, sewage tanks, and drilling mud tanks in oil fields;

- Liquefied natural gas and condensate water from liquefied gas stations;

- Gasoline, diesel, tar, and waste oil from oil storage depots and biodiesel plants;

- Urea melt and ammonia water in compound fertilizer plants;

- Level measurement of various chemical products, high temperature, high pressure and highly corrosive media (such as hydrochloric acid) and toxic products (such as liquid chlorine) in chemical plants.

2. Application of radar level meter in the power industry

In the power industry, radar level meters are mainly used for level measurement in battery fly ash silos, desulfurization, lubricating oil, mud, raw coal bunkers, fuel bunkers, storage pools, flying purification tanks, ash silos, etc.

3. Application of radar level meter in cement industry

In the cement industry, radar level meters are mainly used for level measurement in bulk finished cement silos, raw coal bunkers, coal bunkers, raw material homogenization warehouses, clinker warehouses, and slag storage warehouses in cement plants.

4. Application of radar level meter in metallurgical industry

In the metallurgical industry, radar level meters are mainly used for level measurement of iron ore, limestone raw material, limestone clinker, raw coal bunkers in steel plants, and carbon powder, aluminum ore, and coal powder in aluminum plants.

5. Application of radar level meter in coal industry

In the coal industry, radar level meters are mainly used for level measurement of raw coal, clean coal, cinder, pulverized coal, and coal-containing sewage in coal washing plants.

6. Application of radar level meter in grain storage industry

In the grain storage industry, 26G radar level meters are also widely used. During the storage, custody, and transportation of grain, the level changes of materials can be monitored in real time. This can avoid material blockage or leakage, and improve the utilization rate and storage quality of materials.

7. Application of radar level meter in the field of environmental protection

In the field of environmental protection management, 26G radar level meters also have important applications.

For example, in processes such as wastewater treatment and sludge treatment, liquid levels, material levels, etc. can be accurately monitored and controlled to improve the operating efficiency and treatment effect of environmental protection equipment.

More Featured Level Measurement

- Featured 5 Guided Wave Radar Level Transmitter Types

- Guided Wave Radar Level Transmitter Installation Guide and Troubleshooting

- Difference Between Radar and Guided Wave Radar Level Transmitter

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

Radar level meters are increasingly used in the field of industrial automation. Due to its high precision, high reliability, non-contact measurement and other characteristics, it is widely used in petrochemical industry, steel metallurgy, grain storage, cement building materials, environmental protection and other fields.

Non-Contact 26 GHz Radar Level Meters | High Frequency

26GHZ high frequency Radar Level Meters have the advantages of low maintenance, high performance, high precision, high reliability, and long service life. Compared with contact instruments such as capacitance and hydrostatic pressure, it has unparalleled advantages.

The Radar Level Meters produced and supplied by us at Sino-Inst can meet the requirements of harsh environments such as volatile gases, high temperatures, high pressures, steam, vacuum and high dust during the process. It is suitable for harsh environments such as high temperature, high pressure, vacuum, steam, high dust and volatile gases, and can continuously measure different material levels.

If you need to purchase Radar Level Meters or have related technical questions, please feel free to contact us.

Non-Contact 26 GHz Radar Level Meter | High Frequency

Radar level meter is a non-contact level meter that measures the level of liquid or solid materials. 26 GHz high frequency radar level meter, measuring up to 80 meters.

Product SKU: Non-Contact 26 GHz Radar Level Meters | High Frequency

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 599

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)