802 Series Capacitive Level Sensors are instruments that continuously measure the liquid level (material level) in containers based on the capacitive sensing principle. Can be customized for high temperature measurement of -50-250℃, or high pressure measurement of 32MPa.

Features

- Simple structure without any movable or elastic components. The result is extremely high reliability and minimal maintenance. Under normal circumstances, there is no need to carry out routine major, medium and minor repairs.

- Multiple signal outputs to facilitate different system configurations.

- Suitable for liquid level measurement of high temperature and high pressure vessels. And the measured value is not affected by the temperature, specific gravity of the liquid being measured and the shape and pressure of the container.

- Especially suitable for the measurement of highly corrosive liquids such as acids and alkalis.

- Perfect over-current, over-voltage, and power polarity protection.

Technical Parameters

| examination range: | 0.01~2000m |

| Pressure range: | -0.1MPa~32MPa |

| Detector temperature resistance: | -50~250℃ |

| Ambient temperature: | -20~60℃ |

| Storage temperature: | -55℃~+125℃ |

| Output signal: | 4~20mA, 4~20mA superimposed HART communication, 485 communication, CAN bus communication |

| Supply voltage: | 12~28VDC (need to be powered by safety barrier) |

| Fixing method: | Thread installation M20×1.5, M27×2, flange installation DN25, DN40, DN50. Special specifications can be customized upon request |

| Wet material: | 316 stainless steel, 1Gr18Ni19Ti or PTFE |

| Long term stability: | ≤0.2%FS/year, |

| Temperature drift: | ≤0.02%FS/℃ (in the range of 0~70℃) |

| Explosion-proof level: | Intrinsically safe ExiaⅡC T6 Flameproof ExdⅡC T5 |

| Protection level: | IP67 |

| Intrinsically safe parameters: | Ui: 28VDC, Ii: 93mA, Pi: 0.65W, Ci: 0.042uf, Li: 0mH |

Ordering requires you to confirm the parameters in advance: range; installation method; medium; temperature; pressure;

Featured 802 Series Capacitive Level Sensors

8021 Basic Capacitive Level Sensor

8021 basic type Capacitive Level Sensor, this structure can work for a long time in an environment below 0.6MPa and 100℃.

Suitable for measuring the liquid level of conductive media such as various reservoirs, sewage, baths, acid and alkali solutions, and low-pressure boilers.

8023 High Pressure Capacitive Level Sensor

8023 high-pressure Capacitive Level Sensor, the wetted material is PTFE probe, and the connector is stainless steel. It can work for a long time in an environment of 32MPa and 100℃. It has strong corrosion resistance.

Suitable for measuring conductive media that are not too hot in high-pressure vessels in the chemical industry.

8025 Hygienic Capacitive Level Sensor

8025 hygienic Capacitive Level Sensor is a special instrument customized for food and pharmaceutical, beverage processing, brewing industry, biological products and other industries.

It adopts standard sanitary stainless steel quick connector and integrated PTFE probe structure. There are no sanitary dead corners between the whole machine and the medium.

The long-term working pressure of this product can reach 5MPa, making it the most ideal product for measuring liquid level in related industries.

8026 coaxial sheath type Capacitive Level Sensor

The sensing part of the 8026 coaxial sheathed Capacitive Level Sensor is a coaxial container. When liquid enters the container, it causes a change in capacitance between the sensor housing and the sensing electrode. This change is converted by the circuit and accurately Linear and temperature compensation, output 4-20mA standard signal to display instrument.

8026 coaxial sheath type Capacitive Level Sensor is suitable for measuring various non-conductive liquids. It has strong anti-interference ability. This kind of liquid level sensor is an ideal choice in situations where the liquid level fluctuates greatly.

capacitive level sensor working principle

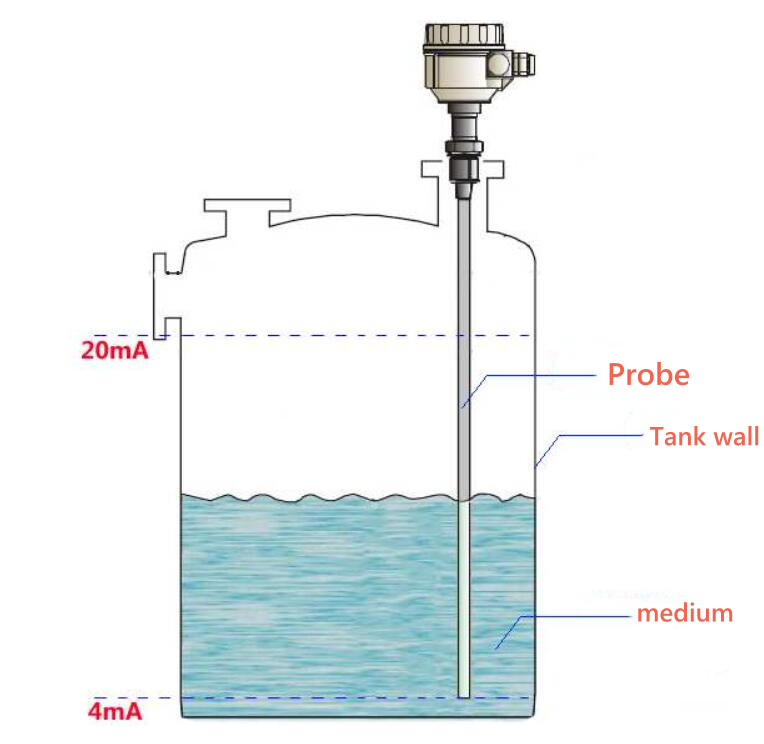

Capacitive Level Sensor measures the level of liquid level by measuring changes in capacitance. It is a metal rod inserted into a liquid container. The metal rod serves as one pole of the capacitor, and the container wall serves as the other pole of the capacitor.

The medium between the two electrodes is the liquid and the gas above it. Since the dielectric constant ε1 of the liquid is different from the dielectric constant ε2 on the liquid surface, for example: ε1>ε2. When the liquid level rises, the total dielectric constant value between the two electrodes of the capacitive level meter increases. Therefore the capacitance increases. On the contrary, when the liquid level drops, the ε value decreases and the capacitance also decreases.

Therefore, the Capacitive Level Sensor can measure the unevenness of the liquid level through changes in the capacitance between the two electrodes. The sensitivity of the capacitive level meter mainly depends on the difference between the two dielectric constants, and only the stability of ε1 and ε2 can ensure accurate liquid level measurement. Because the measured medium is conductive, the metal rod electrodes are covered with an insulating layer .

Capacitive Level Sensor is small in size and easy to implement remote transmission and adjustment. It is suitable for liquid level measurement of corrosive and high-pressure media.

capacitive level sensor Applications

Capacitive level sensors can be used for continuous level measurement of almost all strong and weak corrosive-resistant media and non-corrosive media in open or pressure vessels.

Widely used in: liquid level detection and control in petroleum, chemical industry, fertilizer, metallurgy, natural gas, power plants, machinery manufacturing, ships, pharmaceutical factories, sewage treatment, food, wine industry and other industrial occasions, especially ammonia synthesis system in the fertilizer industry First choice.

Advantages and Disadvantages of Capacitive Level Sensor

Capacitive Level Sensor is a commonly used liquid level measuring instrument with the following advantages and disadvantages:

Advantages:

- High accuracy: Capacitive liquid level gauge can achieve high measurement accuracy.

- Wide measuring range: Capacitive liquid level meter is suitable for measuring the liquid level of different liquids and different media, and has a wide measuring range.

- Can monitor in real time: Capacitive liquid level meter can monitor liquid level changes in real time and feedback liquid level information in time.

- No direct contact with the liquid is required: Capacitive level gauges measure liquid level through changes in capacitance between electrodes on the container wall and the liquid. No direct contact with liquid is required, thus avoiding material corrosion and contamination issues.

Disadvantages:

- Affected by the properties of the liquid: Capacitive liquid level gauges have higher requirements for the dielectric constant of the liquid. When the dielectric constant of the liquid changes greatly, the measurement results may be affected.

- High installation requirements: The installation requirements of the capacitive liquid level meter are high, and it is necessary to ensure the insulation performance between the electrode and the liquid, and the good contact between the electrode and the container.

- Affected by the environment: The measurement results of the capacitive liquid level gauge are affected by factors such as ambient temperature and humidity, and require corresponding compensation or correction.

- Higher cost: Compared with other liquid level measurement methods, capacitive level sensors are more expensive and may not be economical and practical for some low-cost applications.

More Featured Level Measurement

Capacitive Level Sensors are suitable for continuous detection of various liquids under harsh conditions such as high temperature and high pressure, strong corrosion, easy crystallization, and easy clogging. Suitable for measuring sewage, acid and alkali solutions, and boiler water levels. The whole machine does not have any movable or elastic parts, is impact-resistant, easy to install, has high reliability and high precision.

Capacitive Level Sensor can replace traditional float type, input type, differential pressure type and other liquid level transmitters in various applications. Of course, you still need to choose the most suitable level meters based on your actual measurement parameters.

If you need to purchase Capacitive Level Sensors or have related technical questions, please feel free to contact us.

Featured Capacitive Level sensors|High Temp-High Pressure Customization

802 Series Capacitive Level Sensors are instruments that continuously measure the liquid level (material level) in containers based on the capacitive sensing principle. Can be customized for high temperature measurement of -50-250℃, or high pressure measurement of 32MPa.

Product SKU: 802 Series Capacitive Level Sensors for Industrial Level Measurement

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 499

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)