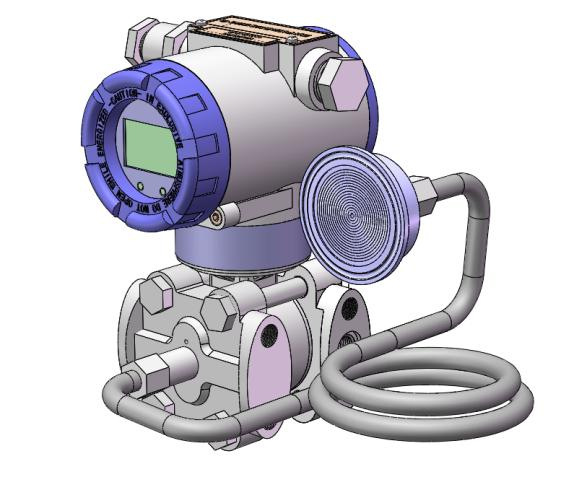

Diaphragm seal is used to prevent media from directly entering the sensor assembly in the pressure transmitter/differential pressure transmitter. Remote split pressure measurement can be achieved by connecting the fluid-filled capillary tube to the transmitter.

Diaphragm seals effectively broaden the application range of pressure transmitters. It makes the measurement of pressure transmitter and differential pressure transmitter safer and more reliable. Diaphragm seal and capillary are ideal choices for protecting pressure instruments and process transmitters even under extreme working conditions such as high temperature and low temperature, and even when the measured medium is corrosive, viscous, viscous or easy to solidify.

What is Diaphragm Seal?

Problems usually do not arise when the process medium comes into direct contact with a pressure gauge, pressure transmitter or other pressure instrumentation. However, harsh media and environments can damage the sensor’s internal pressurized components. In these cases, a diaphragm seal is necessary.

A diaphragm seal is a housing or flexible membrane that protects many types of pressure instruments. This seal is flexible so it can saturate the interior from external pressure but securely seal the contents. Can be installed together with pressure gauges, switches, and transmitters.

Why use a diaphragm seal?

Diaphragm seals are protective devices designed to isolate pressure gauges, pressure transmitters and pressure switches from potentially damaging process media. Properly designed diaphragm seals can provide protection with minimal impact on accuracy. Diaphragm seals therefore extend the service life of pressure measuring instruments. In the long run, it is the most cost-effective solution!

Diaphragm seals can also be mounted remotely from the pressure port via capillary tubing. The wide variety of available process connections (flanged, threaded, etc.) can be customized to meet many industry standards.

Benefits of Diaphragm Seal for Pressure Measurement Systems

The purpose of a diaphragm seal is to isolate the pressure measuring instrument from the process medium.

In addition to the obvious advantages of isolating the instrument from its contents, there are several other advantages:

- Helps prevent liquid clogging and crystallization.

The risk of corrosion or any reaction of fluids with these primarily metallic devices is removed. Enables the instrument to operate over a wide temperature range and in a variety of toxic liquids and semi-solids. Depending on application requirements, some types are threaded and flanged to facilitate remote installation via capillary tubing. - Helps extend the service life of closed instruments.

Bearings are protected with minimal impact on accuracy. In this way, the service life of the pressure measuring instrument is extended, saving the user a lot of time in the long run. - Remote transmission installation.

Allows remote installation from the pressure port by customizing capillary tubing to fit your application, and thanks to the wide range of process connections available (flanged, threaded, etc.) they can meet many industry standards. - Suitable for high and low temperatures.

When using a diaphragm seal, the measuring instrument can be used in temperatures from −130 to +750°F (−90 to +399°C). - Compatible with more measurement media.

Can be used with corrosive, corrosive, heterogeneous, abrasive, highly viscous or toxic media. The design, materials and filling fluids can be used in many demanding industrial applications such as bioethanol production, fertilizer production and wastewater filtration.

Products we are familiar with include: Rosemount™ 1199 Diaphragm Seal System, EJA118W / EJA118N / EJA118Y and other products.

What is a capillary tube?

The capillary tube is a section of conduit that connects the pressure source contact surface to the pressure gauge. It is deformable and controllable. Its main function is to prevent factors such as temperature or vibration of the pressure source from causing errors in the correct data of the instrument. It is filled with high-temperature silicone oil. Keep the transmitter out of contact with the measuring medium.

The capillary tube is not a pressure guiding tube, the pressure guiding tube is an ordinary pipe. The pressure guiding tube cannot separate the medium and the pressure sensor. But the capillary tube can.

Benefits of Capillary Tube for Pressure Measurement Systems

- Long-Distance Pressure Transmission

When the measurement point is some distance from the pressure transmitter, directly introducing the medium (e.g., gas, liquid, steam) into the transmitter can be problematic. Capillary tubes can transmit pressure over longer distances, allowing the transmitter to be placed in a more suitable location for maintenance or monitoring.

For example, when measuring steam pressure, the transmitter may be damaged by high temperatures; capillary tubes keep the transmitter away from the high-temperature source.

- Media Isolation

Capillary tubes are often used in conjunction with diaphragm seals, which isolate the measured medium from the pressure transmitter, preventing direct contact. This prevents corrosive or viscous media from entering the transmitter, protecting it from damage. Examples include acidic or alkaline liquids or high-temperature steam. Corrosive media require diaphragms made of special materials.

- Control of Thermal Effects

In high-temperature applications, directly connected pressure transmitters can be damaged by the high temperature. For example, when measuring boiler steam pressure. By using capillary tubes, a suitable conductive fluid can be filled inside, effectively reducing the impact of temperature on the pressure transmitter. For example, high-temperature silicone oil. This liquid transmits pressure signals without transferring heat, protecting the transmitter from high-temperature damage.

- Reduced Vibration Effects

When there is severe mechanical vibration at the measurement point, directly installing the pressure transmitter may affect measurement accuracy or damage the transmitter. Using a capillary tube, the transmitter can be installed away from the vibration source, thereby reducing the impact of vibration on measurement accuracy.

Featured remote seal pressure transmitters

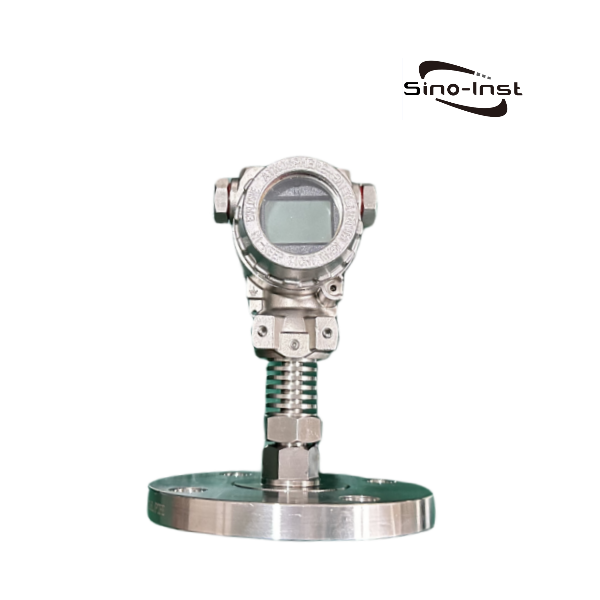

3151T flange type remote pressure transmitter

The selection is as follows:

3151TGP4SF00S1M4B4 0~40kPa

1199FFW A50AADL03H00

On behalf of the 3151TGP base table plus an American standard 2”150LB flange type remote transmission device, the capillary length is 3 meters. For the specific flange size and selection, please refer to the 1139FFW flange type remote transmission device flange specification drawing and selection specifications table.

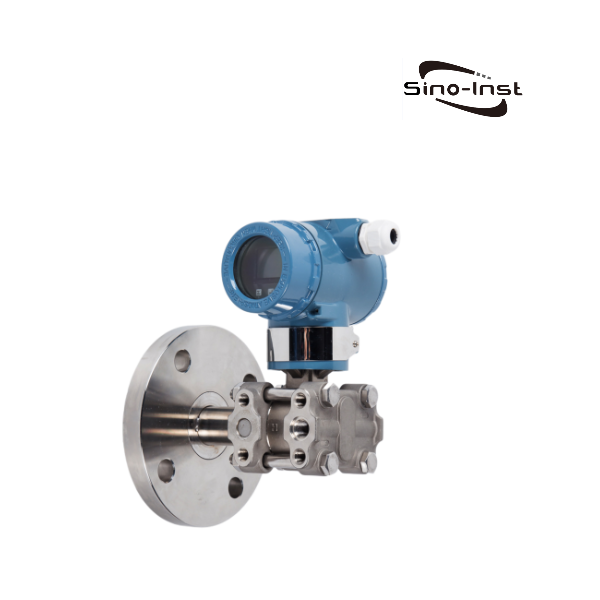

3151GP/DP type three clamp type remote pressure transmitter

The selection is as follows:

3151TGP5SF22S1M4B3 0~100kPa

1199SCWA1A0DL03H00

On behalf of the 3151GP base table plus a three-clamp type remote transmission device, the capillary length is 3 meters, the user connection clamp specification is 1 1/2 inch. For the specific size and selection, please refer to the specification of the 1199SCW three-clamp type remote transmission device and Selection specification sheet.

We only list a few here. If you need other models, please contact our sales engineers!

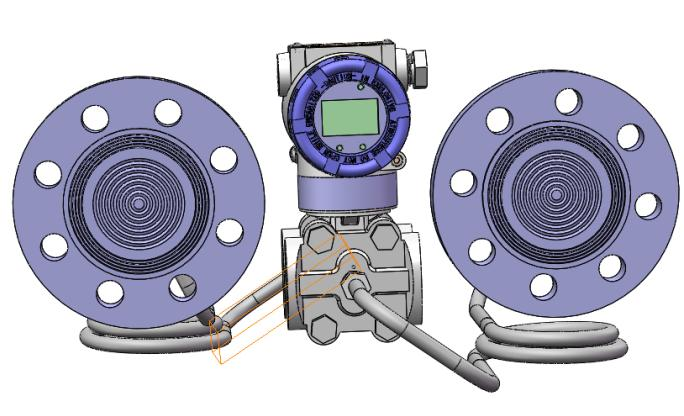

Featured remote seal differential pressure transmitters

3151DP double flange type remote differential

pressure transmitter

The selection is as follows:

3151DP4SF22S2M4B3 0~40kPa

1199FFW A50AADL03H00

1199FFW A50AADL03L00

On behalf of the 3151DP base table plus two American standard 2″150LB flange type remote transmission device, the capillary length is 3 meters. For the specific flange size and selection, please refer to the 1139FFW flange type remote transmission device flange specification and selection Specification Table.

We only list a few here. If you need other models, please contact our sales engineers!

Typical applications

Diaphragm sealed pressure transmitters and diaphragm sealed differential pressure transmitters can provide you with cost-effective solutions. Typical applications are:

- In applications where the process fluid is corrosive and clogged;

- In applications where the process fluid has high viscosity, consists of slurry, sludge or other materials that may actually cover or damage traditional pressure measurement equipment.

- In the event that the process fluid freezes or aggregates, resulting in a condition that may cause the instrument to fail to hold or transmit accurate pressure measurements or signals.

- Measurement under extremely hot or cold temperatures;

- Food, medicine and other hygienic environmental requirements;

- Need to customize special process connections;

- Can be used for liquid level measurement, flow measurement, pressure measurement, differential pressure measurement, interface measurement, and density measurement;

More pressure measurement solutions

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

Diaphragm seal pressure transmitters and diaphragm seal differential pressure transmitters can be used to measure the flow, liquid level, density and pressure of high and low temperature, high vacuum, high viscosity and easily crystallized media. And convert it into a 4~20mA DC current signal output.

We at Sino-Inst produce a wide range of custom-made pressure/differential pressure transmitters with diaphragm seals and capillary systems for a variety of industries and processes. Includes various grades of stainless steel and alloys for wetted materials, as well as a variety of standard flanges, capillaries and cooling elements.

If you need to purchase a diaphragm seal pressure transmitter and a diaphragm seal differential pressure transmitter, please feel free to contact our sales engineers!

-1.jpg)