You need to measure pressure, so you are going to purchase a pressure transmitter. Then you will find that there are many types of pressure sensors on the market. You will see capacitive pressure transmitter, MEMS pressure sensor, absolute pressure transmitter, differential pressure transmitter, pressure transmitter diaphragm type, 4-20mA pressure transmitter and many more.

So through this article, I hope you can have a preliminary understanding of Industrial Pressure Transmitters and their types.

What is a Pressure Transmitter?

A pressure transmitter is an instrument that converts the pressure of a fluid (such as a gas or liquid) into an electrical signal output. In addition to measuring and displaying real-time pressure values, the signals output by the pressure transmitter (4-20mA, 0-5V, RS485, etc.) can be used to indicate secondary instruments such as alarms, recorders, and regulators.

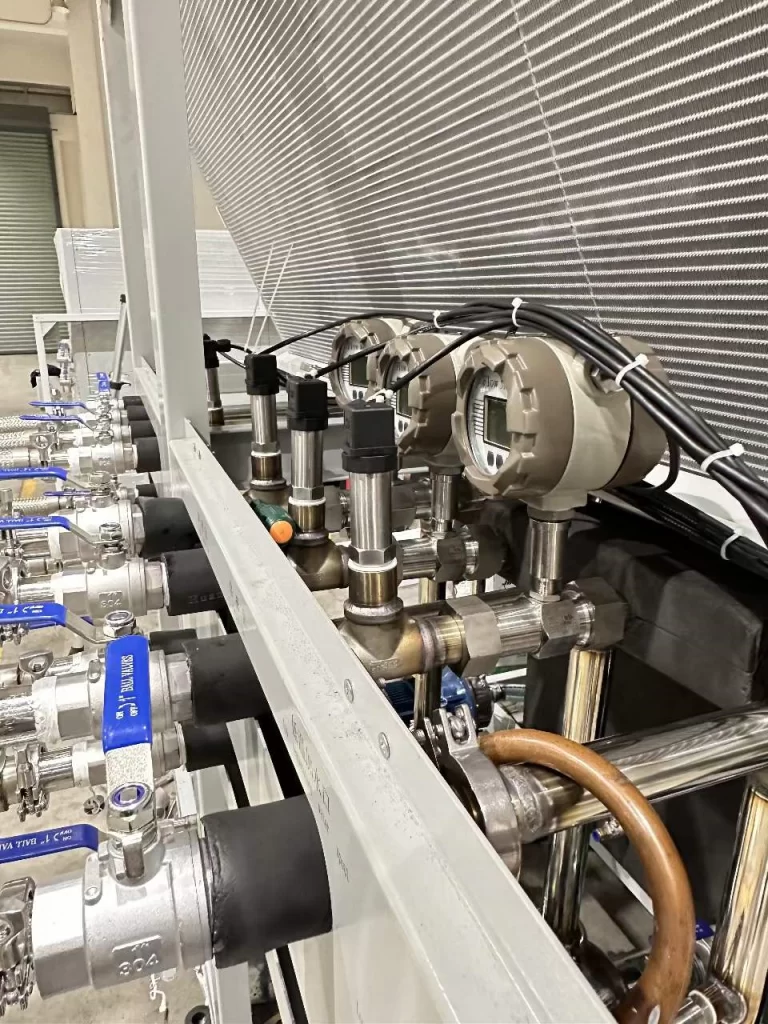

In industrial control systems, pressure transmitters are very important. Widely used in various industrial processes such as filtration plants, chemical raw materials, wastewater industry, food industry, pumping stations, etc.

Our Sino-Inst pressure transmitters can be customized based on pressure range, accuracy, connection type, output, IP rating, wetted materials and even more variables.

Pressure Type

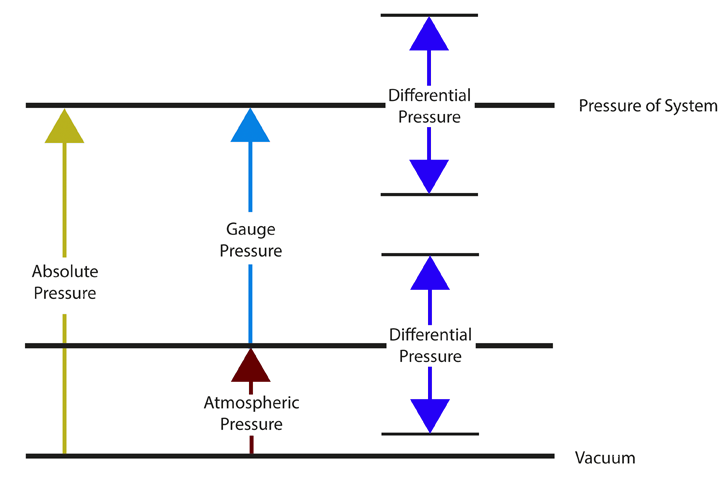

There are three main types of pressure that a pressure transmitter can measure: absolute pressure (Absolute Pressure), gauge pressure (Gauge Pressure) and differential pressure (Differential Pressure).

7 Pressure Sensor Principles

The following are the measurement principles of these seven pressure sensors and their advantages and disadvantages:

Metal capacitive type:

Principle: Metal capacitive pressure transmitter uses metal film as the sensing element. When subjected to pressure, the membrane deforms, changing its capacitance value. High-precision circuitry on the measuring diaphragm converts this tiny deformation into a highly linear voltage signal that is proportional to the pressure and proportional to the excitation voltage. A dedicated chip is then used to convert this voltage signal into an industry-standard 4-20mA current signal. Or 1-5V voltage signal.

Advantages: Little affected by temperature, suitable for use in situations with a wide temperature range and low accuracy requirements.

Disadvantages: The accuracy is generally 0.5%FS. Not as accurate as monocrystalline silicon.

Ceramic type:

Principle: Using the piezoelectric effect of ceramic materials, the pressure causes the ceramic film to deform. The thick film resistor is printed on the back of the ceramic diaphragm. Due to the piezoresistive effect of the varistor, it is connected to a Wheatstone bridge (closed circuit bridge). This resistor The bridge produces a highly linear voltage signal that is proportional to pressure and proportional to the excitation voltage.

Advantages: high precision, impact resistance, corrosion resistance.

Disadvantages: Largely affected by temperature.

Diffused silicon type:

Principle: The pressure of the measured medium directly acts on the diaphragm of the sensor (usually a 316L diaphragm), causing the diaphragm to produce a micro-displacement proportional to the medium pressure. Change the resistance value of the sensor and use a Wheatstone circuit to change it. And convert and output the standard measurement signal corresponding to the pressure. At room temperature, the sensitivity coefficient of diffused silicon is 5 times that of ceramics, and is usually used in high-precision measurement fields.

Advantages: high precision and high sensitivity.

Disadvantages: large temperature drift, requiring temperature compensation.

Monocrystalline silicon type:

Principle: Use single crystal silicon as an elastic element. When the pressure changes, the single crystal silicon generates strain, causing the strain resistance directly diffused on it to change proportional to the measured pressure, and then obtains the corresponding voltage output through the bridge circuit Signal. Monocrystalline silicon pressure transmitters are the most accurate sensors in industrial practice and are an upgraded version of diffused silicon.

Advantages: Highest accuracy, suitable for precision measurements.

Disadvantages: higher cost.

Sapphire type:

Principle: Utilizing the high stability of sapphire material, pressure can be measured accurately even under harsh conditions.

Advantages: Sapphire pressure transmitter is not sensitive to temperature changes and has good working characteristics even under high temperature conditions. Sapphire material has extremely strong radiation resistance, does not produce PN drift, and can work normally under the harshest working conditions.

Disadvantages: higher cost, limited application scenarios.

Sputtering film type:

Principle: Sputtering technology is used to form a stable Wheatstone bridge on the elastic stainless steel membrane. When the pressure of the measured medium acts on the elastic stainless steel diaphragm, the Wheatstone bridge on the other side generates an electrical output signal proportional to the pressure.

Advantages: good long-term stability, resistant to temperature effects, suitable for situations with frequent pressure shocks, such as hydraulic equipment.

Disadvantages: The technology is complex and the cost is high.

Strain type:

Principle: The most commonly used strain gauge pressure transmitters are metal resistance strain gauges and semiconductor strain gauges. Usually the strain gauge is tightly bonded to the mechanical strain matrix by a special adhesive. When the base body is subjected to stress changes, the resistance strain gauge will also deform, causing the resistance value of the strain gauge to change, thereby causing the voltage applied to the resistor to change.

Strain gauge pressure sensors are relatively rare on the market.

4 Main Types of Industrial Pressure Transmitters

Although there are many measurement principles for pressure sensors, there are 4 types of industrial pressure transmitters commonly used on the market. They are differentiated based on the type of pressure.

Featured Industrial Pressure Transmitters

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Pressure Transducer Troubleshooting: Expert Insights & Tips

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- Steam Pressure Sensor/transducer for Industrial Steam Measurement

- What Is a 4 to 20 Milliamp Signal?

- Gauge Pressure vs Absolute Pressure | Differences and Relationships

- Industrial Water Pressure Sensors | Selection Guide

- How to calibrate a pressure transmitter? How often?

- 10 Point Guide! Selection of Pressure Transmitters

Industrial Pressure Transmitters are commonly used for pressure control, monitoring and measurement. Pressure transmitters are very important in industrial control systems and are widely used in various process control and monitoring scenarios, such as oil and gas, chemical industry, electric power, environmental protection, water treatment and other industries.

Selecting the appropriate pressure transmitter type according to actual needs can achieve accurate measurement and control of pressure signals. We at Sino-Inst are manufacturers of Industrial Pressure Transmitters. Our Industrial Pressure Transmitters are more than 50 types and widely exported to various countries. Including the United States, the United Kingdom, India, South Africa, etc.

Whether it is absolute pressure, gauge pressure or differential pressure, Sino-Inst can provide the appropriate measurement solution. If you need to purchase Industrial Pressure Transmitters or have related technical questions, please feel free to contact us.

You can also contact our sales to obtain the pressure transmitter types PDF.

-1.jpg)