An electromagnetic flow meter is an instrument that measures the flow rate of conductive fluids by utilizing the induced voltage generated by the fluid. Because electromagnetic flow meters are designed not to introduce protrusions or obstructions in the pipeline, they are suitable for a wide range of applications, from clean liquids to slurries and highly corrosive or abrasive fluids.

Case Study

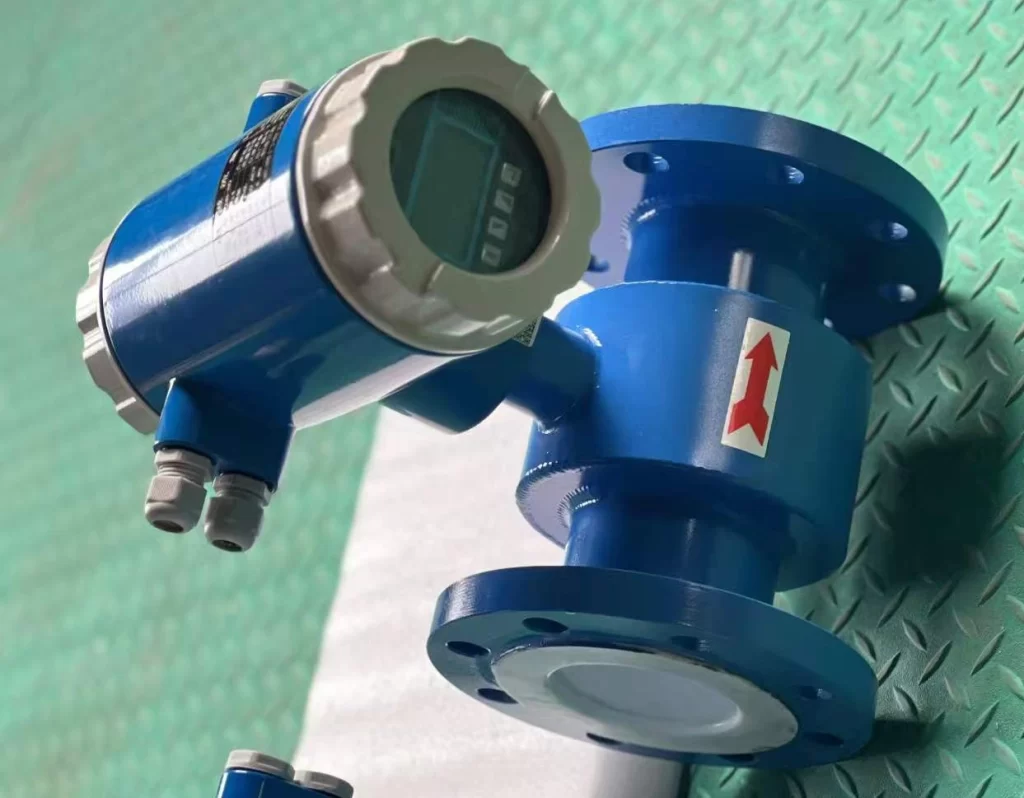

A customer from Australia wanted to measure the flow rate of a lime slurry containing 25% calcium oxide. However, the slurry flow rate was very low, and the customer’s pipeline was a little large. Taking all factors into consideration, we recommend using a small electromagnetic flow meter equipped with Hastelloy electrodes and a PTFE lining to prevent media corrosion. Furthermore, due to the large size of the customer’s pipeline, we offer a reducing section. Parameters are as follows:

- Electromagnetic Flowmeter

- DN5 Sensor

- Media: Lime Slurry (25% CaO)

- Flow Range: 1-8 L/min

- PTFE Liner

- Hastelloy Electrode

- Temperature: 20-80℃

- Rated Pressure: 1.6 MPa

- Power Supply: 24VDC

- Output: 4-20mA+RS485DN15 Flange Connection

Working Principle

Electromagnetic flow meters use Faraday’s law of electromagnetic induction to detect flow rate. They consist of a transmitter and a sensor. Inside the sensor is an electromagnetic coil that generates a magnetic field. There are also electrodes for capturing voltage.

When the pipe is filled with fluid, the fluid flows, and the force in the magnetic field causes positive and negative particles in the fluid to separate as they pass through the magnetic field. This separation induces a voltage between the electrodes and the sensor. This voltage is proportional to the pipe diameter, the magnetic field strength, and the average flow velocity. The induced voltage enters the transmitter through the electrode circuit. The transmitter then converts this voltage into a quantifiable flow velocity. Using this known velocity and the pipe area, the volumetric flow rate of the fluid can be calculated.

Product Features

- Simple structure, no rotating parts. Therefore, there is no friction, long service life, high measurement accuracy, and reliable performance.

- There are no throttling or flow-blocking components in the sensor measuring tube, therefore there is no additional pressure loss and no clogging problem. It is suitable for measuring two-phase flows containing suspended solids, solid particles, fibers, etc. (such as slurries with high viscosity, such as mud, sewage, mineral slurry, and pulp).

- Since the signal is formed throughout the entire space filled with the magnetic field, it is an average value on the pipe plane. Therefore, the required straight pipe length from the plane electrode to the upstream end plane of the sensor is relatively short, 10D (D is the inner diameter of the pipe).

- No mechanical inertia, sensitive response, can measure instantaneous pulsating flow, and can also be combined with unit combination instruments and computers to form various automatic detection, regulation, and programmable control systems.

- The sensor output signal is an electromotive force that is precisely linearly related to the average flow velocity, and the measurement result is independent of the physical parameters of the liquid, such as temperature, pressure, density, or viscosity.

- It has 4-20mA current signal output, pulse output, and instantaneous flow rate upper and lower limit alarm output. RS485 communication and HART protocol are optional.

- It can display instantaneous flow rate, percentage, flow velocity, forward and reverse cumulative flow, and total cumulative flow on-site.

- You can customize the lining and electrode materials to suit different media.

Product Limitations

- It cannot detect non-conductive liquids.

- Its installation requires a short straight pipe section.

- It is not suitable for extra-large diameter pipelines.

Application Scenarios

1. Agriculture

Crops require adequate water for growth. For convenience, we often draw water from nearby reservoirs or river dams, which typically contain impurities such as garbage and mud. Using electromagnetic flow meters to record water flow can help control irrigation water usage, increase crop yields, and reduce water waste.

2. Chemical Production

Chemical synthesis requires different liquids for reactions. These liquids are often acidic or alkaline. Using electromagnetic flow meters can help control the volume of different reaction liquids, avoid chemical corrosion, and save costs.

3. Water Treatment

People’s daily water supply comes from waterworks. Waterworks need to measure and collect water fees. Wastewater from sewage treatment plants usually contains various impurities. Electromagnetic flow meters can help us accurately measure and charge for water, and can also help us with pollution control and treatment.

More Options For Small Flow Measurement

1. Small Electromagnetic Flow Meter: For measuring the flow rate of conductive liquids containing impurities in small-diameter pipes, at low flow rates, our small electromagnetic flow meter is an excellent choice. It can measure pipes with diameters of DN10 and below. The reference measurement range for the DN2 flow meter is 3.4-135 L/h.

2. Gear Flow Meter: The gear flow meter contains a pair of cylindrical gears. It measures the volume of flowing liquid using the fixed volume between the gears. No straight pipe section is required for installation. It is suitable for measuring high-viscosity, low-flow-rate fluids. Accuracy is up to 0.5%. Additionally, our gear flow meter can measure media such as liquid nitrogen at -196℃ and asphalt at 200℃. It has a maximum pressure resistance of 40MPa. The reference flow range for GF02 is 0.6-50 L/h.

3. Turbine Flow Meter: The turbine flow meter’s measurement is based on the torque balance principle. The impeller material is 2Cr13. Our small turbine flow meter is suitable for small-diameter pipes from DN2 to DN10 and can measure low-viscosity, clean fluids. Furthermore, you can customize cryogenic turbine flow meters for measuring cryogenic liquid nitrogen. The reference flow range for DN2 is 30-180 L/h.

4. Clamp-on Ultrasonic Flow Meter: Our clamp-on ultrasonic flow meter uses a non-contact measurement method, with no moving parts, no pressure loss, and is easy to install. It can be used to measure the flow rate of clean, single, homogeneous liquids in small-diameter pipes. The measurement velocity range is 0.1-5 m/s. The minimum measurable pipe diameter is DN6, and the reference flow range is 0.34-11.02 L/min.

More Solutions For Liquid Flow Measurement

Sino-Inst’s intelligent electromagnetic flow meter uses the latest technology. It combines the advantages of rectangular wave magnetic fields with the disadvantages of sinusoidal wave magnetic fields. It can also eliminate errors caused by power supply voltage fluctuations, power supply frequency changes, and excitation coil impedance changes. It has excellent zero-point stability and is unaffected by fluid noise interference. Therefore, the product has high reliability and high stability. If you have flow measurement needs, please contact our technical staff.

-1.jpg)