Air flow measurement is critical in various industrial, automotive, healthcare, and HVAC applications. Many industries call for the measurement of airflow or air velocity. They sometimes ask for some additional requirements like the determination of air temperature, air pressure, or humidity. This is true in electronics and automobile engineering, as well as critical containment applications in laboratories, pharmacies, and HVAC.

This blog analyzes different types of air flow meters, including digital air flow meters and the Karman vortex air flow sensor, to provide a clear-cut perceptive of how these technologies work and their applications.

Definition of Air Flow Measurement

At its core, air flow measurement refers to the distance traveled per unit of time. It is most often showing in feet per minute (FPM). Multiplying air velocity by the area of a duct determines the volume of air flowing past a point in the duct during a specified unit of time. Volume flow is typically measured in cubic feet per minute (CFM).

There are different methods to measure air flow, and the choice of technique depends on the application, the medium being measured, and the level of precision required.

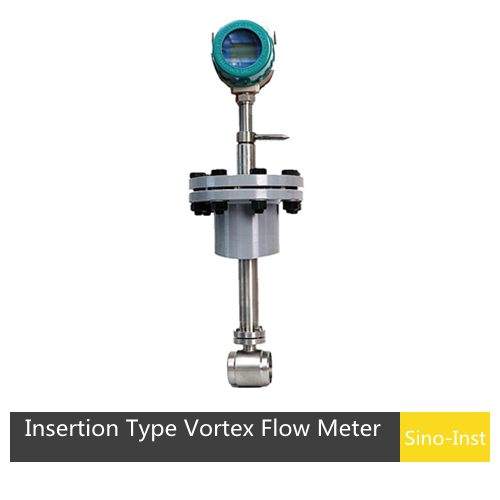

Featured digital air flow meters

The digital air flow meter is a modern-day variation of traditional flow meters, integrating digital technology for improved accuracy, real-time data output, and ease of integration with digital systems like SCADA and Building Management Systems (BMS).

Digital air flow meters alter the measured airflow into digital signals, which can then be processed, analyzed, and displayed on monitors or sent to control systems for automation purposes. This property makes digital air flow meters a favourite choice for industrial air flow measurement applications, including HVAC systems, clean rooms, and process control industries.

Varieties of Air Flow Meters: Let’s dive deep into different varieties!

There are different types of airflow meters based on the principle they operate on. These include:

- Mass Air Flow Meter

- Karman Vortex Air Flow Sensor

- Thermal Air Flow Meter

- Differential Pressure Air Flow Meter

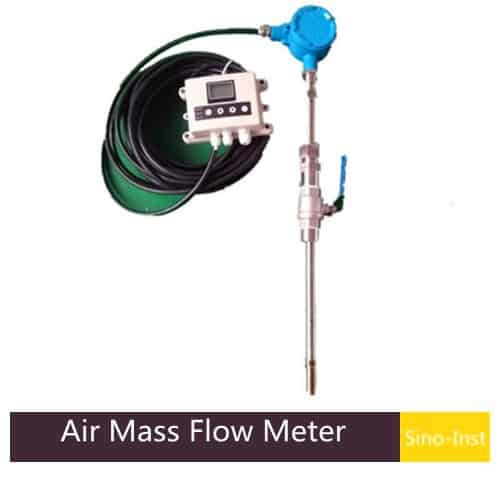

Mass Air Flow Meter: Preciseness in Industrial Instrumentation and Healthcare

It’s more commonly known as a MAF sensor, air meter or sometimes simply MAF. While it might have many names, it’s responsible for just one crucial job-measuring the amount of air entering the engine.

Mass air flow meters are used for wide variety of applications including:

- Air conditioning systems

- Ducting systems in buildings (elevators)

- Automotive cooling systems

- Industrial ventilation systems

The mass air flow meter has respective benefits:

- It provides highly accurate data, crucial for engine management systems.

- It helps improve fuel efficiency in vehicles by enabling precise fuel injection based on the measured air intake.

- It can be used in industrial settings where the mass of air (rather than just the volume) needs to be controlled.

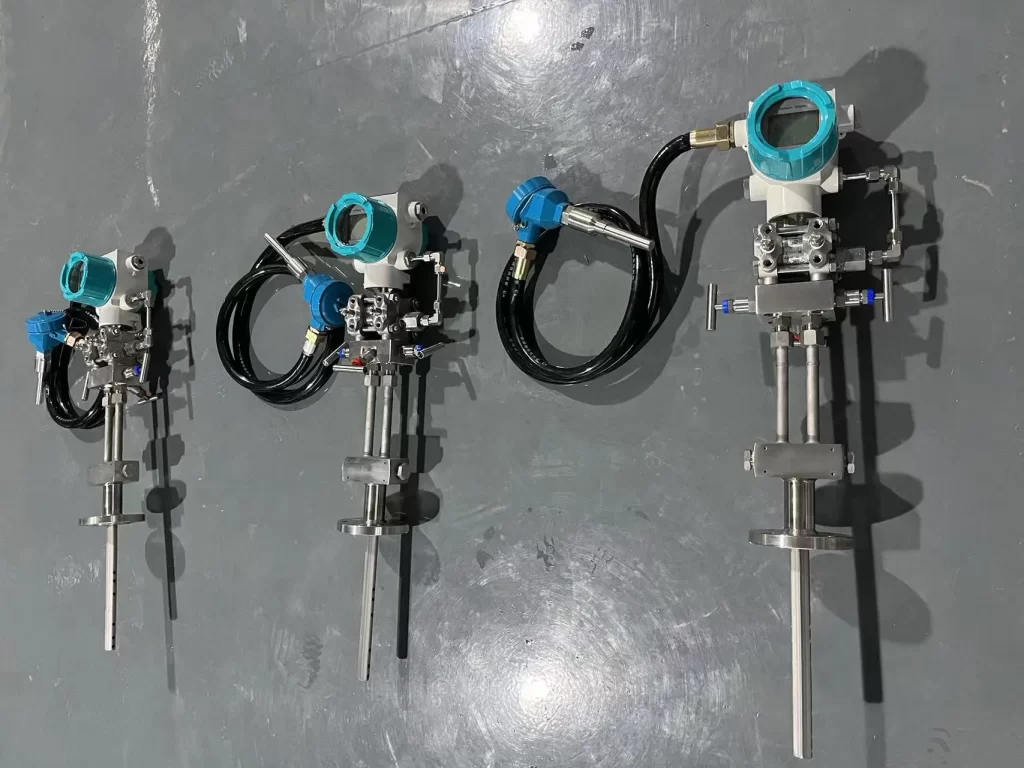

Karman Vortex Air Flow Sensor: Innovative Flow Sensing Technology

The Karman vortex air flow sensor works on the rule of vortex shedding. When air flows past an object, vortices are generated at particular intervals behind the object. The frequency of these vortices is directly proportional to the velocity of the air, allowing the sensor to calculate the air flow rate.

This method is popular in industrial applications due to its high accuracy and reliability, particularly in environments where the flow conditions might be turbulent or contain particulate matter.

Key Benefits of Karman Vortex Sensors:

- Integrated pressure and temperature compensation, integrated energy calculator.

- Various designs: From version with reduced nominal diameter to dual device with two flow converters

- High long-term stability: no zero-point drift and lifetime K-factor

- Large turndown of typically 10:1 to 30:1 for gas/steam, or up to 40:1 for liquids

- Wide temperature range: –200 to +400 °C (+450 °C on demand)

Thermal Air Flow Meter: Ease of Use

Thermal mass flow meter technology applies the relationship between flow rate and cooling effect for direct measurement of mass flow. With no moving parts and minimal invasiveness, thermal flow meters provide a highly repeatable, accurate, low cost, easy to install solution for air and gas flow measurements.

- Benefits of Thermal mass flow meters:

- True mass flow meter, no need an temperature and pressure compensation.

- Wide range ratio, it can be up to 1:200, can measure gas velocity from 100Nm/s to 0.5Nm/s.

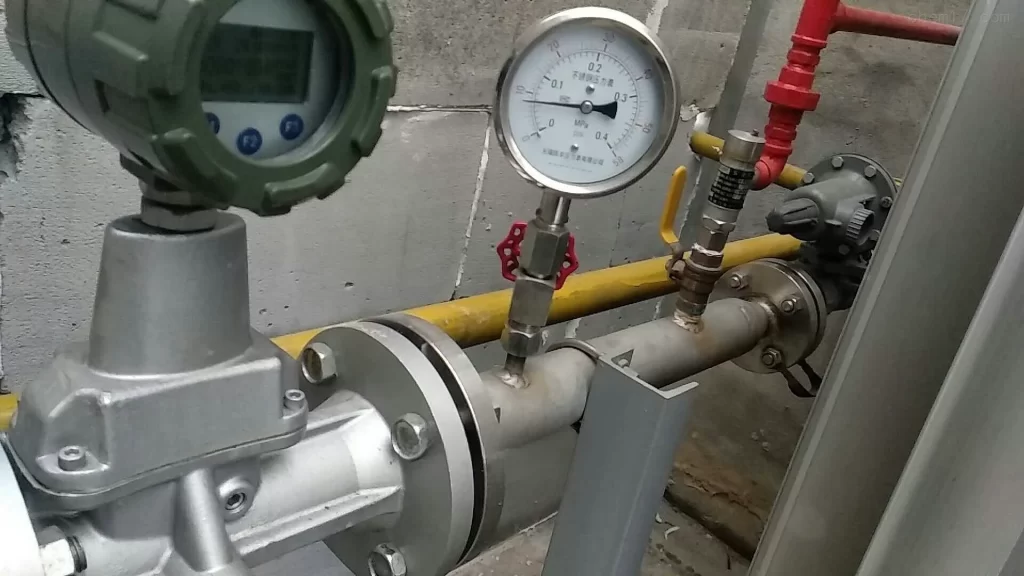

Differential Pressure (DP) flow meter: Another great addition to air flow measurement

Differential Pressure (DP) flow meters initiate a constriction in the pipe that creates a pressure drop across the flow meter. This technology is fit for applications, including DP measurement across filters, heat exchangers, backflow preventers, pipelines, ducts and more.

Choosing the Right Air Flow Measuring Device

Selecting the right air flow measuring device depends on various factors, including the application, required accuracy, operating conditions, and cost.

Below are key considerations when choosing a flow meter:

- Type of Measurement: Do you need to measure the mass or volume of the air flow? Mass air flow meters are ideal for applications that require mass flow data, while digital air flow meters provide high-precision volumetric flow measurements.

- Accuracy Requirements: Different applications have different precision needs. For example, automotive engines require precise air intake measurements to ensure fuel efficiency, while HVAC systems may tolerate slightly less accuracy.

- Operating Environment: Harsh industrial environments with extreme temperatures, high pressure, or particulate-laden air may require more robust solutions like the Karman vortex air flow sensor.

- Integration with Other Systems: Many modern applications, especially in smart buildings and automated factories, require flow meters that can integrate with digital control systems. Digital air flow meters are typically better suited for these environments.

- Cost-effectiveness: The cost of air flow measurement devices varies depending on the technology. While mass air flow meters and Karman vortex sensors offer high precision, they are generally more expensive than simpler digital air flow meters used in HVAC systems.

More Flow Measurement Solutions

- Inline Compressed Air Flow Meters

- Steam Flow Meters

- Natural Gas Flow Meter

- Industrial Liquid Nitrogen Flow Meters

- Top Guide to CO2 Flow Meters

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

Understanding the capabilities and weaknesses of different air flow measurement disciplines allows engineers and technicians to make informed decisions about the best instrument for their specific needs, ensuring operational skillfulness, regulatory abidance, and overall system execution.

Whether you’re working in automotive design, HVAC, healthcare or industrial process management, choosing the right air flow meter is a hypercritical step in achieving optimal results. Sino-Inst is committed to providing you with efficient air flow measurement solutions. Please feel free to contact our engineers!

-1.jpg)