Crude oil is unrefined oil extracted directly from the ground. Crude oil contains hydrocarbon fluids, water and various impurities. Unprocessed crude oil is mainly traded as a commodity.

In oil production and trade measurement, it is important to choose a suitable crude oil flowmeter. Many forms of flowmeters can achieve crude oil measurement.

Methods of Crude Oil Measurement: From Wellhead to Pipeline

| Application | Flow metering technology |

| Well testing | Coriolis, vortex,electromagnetic, turbine,positive displacement,ultrasonic flow meters andmultiphase meters |

| Wellhead | DP flow and multiphasemeters |

| Enhanced oil recovery,water flood, steam flood,miscible flood, chemical flood | Coriolis, vortex,electromagnetic, turbine andultrasonic flow meters |

| Processing, separation,crude oil desalting, crudeoil dehydration, crude oilstabilization, condensatestabilization, gas dehydrationgas sweetening, stock tankvapor recovery, water treatment | Coriolis, vortex,electromagnetic, turbineand ultrasonic flow meters |

| Transportation, LACT units,gathering, truck and rail carloading and unloading | Coriolis, positivedisplacement and turbineflow meters |

crude oil measurement Measurement methods

1.Volumetric Measurement:

Positive Displacement Meters: Positive displacement flow meter is an device that accumulates flow straightaway based on the volume of discharged fluid or gas. Positive displacement flow meter is referred to as PD flow meter, which is a type of flow meter with higher accuracy.

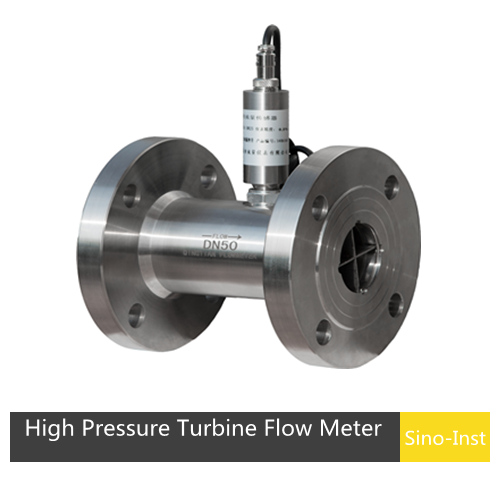

Turbine Meters: These utilize a turbine that spins in response to the flow of oil. The rotational speed of the turbine correlates with the flow rate, allowing for accurate measurements.

2.Mass Measurement:

Mass flow meters are becoming more and more popular for crude oil measurement due to their preciseness. These meters use the principle of the Coriolis effect, which measures the mass of the liquid as it flows through the meter. They are less affected by temperature and pressure variations compared to volumetric meters, making them suitable for varying conditions.

3.Radar and Ultrasonic Measurement:

These non-contact methods are used for measuring levels in storage tanks. In recent years, with the continuous development and improvement of the radar level meter industry, more and more users choose to use radar level meters to measure the level of crude oil storage tanks, and also achieved good results.

4 reasons why radar level is superior to ultrasonic level technology:

- Radar level technology is not affected by ambient conditions

- Radar technology is not affected by process conditions

- Radar level technology is easier to setup

- Cost-effectiveness

Read more about: Difference Between Radar and Ultrasonic Level Transmitter

4.Weight Measurement:

This method involves weighing the crude oil in a tank or container. While this method can be highly accurate, it is less commonly used for large quantities due to logistical challenges.

5.Water Cut Measurement:

This is carping for understanding the quality of crude oil. Water cut refers to the percentage of water present in the oil. Various techniques, including centrifuges and optical sensors, are employed to determine the water content accurately.

Featured crude oil flow meters

Bottlenecks in Crude Oil Measurement:

- Density Variations: Crude oil is not homogeneous. Its density can vary significantly based on its composition. This variability can complicate the measurement process, especially in mass flow measurements.

- Environmental Issues: Variations in temperature and pressure can affect the accuracy of volumetric measurements.

- Instrumentation Calibration: Regular calibration of measurement equipment is indispensable to maintain accuracy. However, this process can be time-consuming and costly, leading to potential lapses in measurement reliability.

- Cost Considerations: While more advanced measurement systems offer greater accuracy, they often come at a higher cost. Operators must weigh the benefits against the investment required.

More Flow Measurement Solutions

- Industrial Refrigerant Flow Meters

- Getting to Know The Propane Flow Meters: Better Monitoring of Propane Utilization

- Importance of Digital Fuel Flow Meters and Fuel Oil Flow Meters in Modern-day Industrial Applications

- Techniques, Importance, and Challenges of Natural Gas Flow Measurement

- DP Transmitter for Flow Measurement

- Guide To Vortex Flow Meters For Steam Applications: Steam Vortex Flow Meter In detail

- 4-20mA Flow Meters | Flow Meter Signal Output Guide

- Analog Flow Meters: An Encompassing Guide

- Industrial Hydraulic Flow Meters | Mechanical & Digital

Flow rate measurements help scientists and engineers determine the volume of pollutants emitted into the environment, helping to identify and prevent environmental harm. Flow rate measurements are important in the management of energy resources such as oil, gas, and water.

Sino-Inst is a Professional flow meter manufacturer and supplier. We have a wide range of Flow meter solutions. Positive Displacement Flow Meters and Mass Flowmeters are ideal for crude oil measurement methods. If you have related technical questions, please feel free to contact our engineers!

-1.jpg)