Why Natural Gas Flow Measurement is Pivotal?

Natural gas is a vital energy source, providing electricity to industries, homes, and businesses worldwide. High-precision natural gas flow measurement is essential for ensuring fair trade, accurate trade measurement, and safe and efficient energy distribution.

This article delves into the field of natural gas flow measurement, introducing various measurement technologies, the importance of accurate measurement, and the challenges faced by different industries.

Sino-Inst is a Professional flow meter manufacturer and supplier. A wide variety of natural gas flow meter options are available to you here at Sino-Inst. Flow meter products are most popular in the Domestic Market, Southeast Asia, Europe, and America.

Why Is accurate measurement vital?

Natural gas, like other commodities, needs to be measured accurately during its extraction, processing, transportation, and distribution. The reasons are manifold, from ensuring proper billing and taxation to ensuring system safety and efficiency.

Here are some reasons why natural gas flow measurement is essential:

- Economic Impartiality

- System Adaptability

- Compliance with Regulations

- Safety issues

The Challenges in Natural Gas Flow Measurement

Different challenges may arise, requiring careful consideration and attention for every application that calls for gas flow measurement. Some of these challenges include:

- Capacity to accurately measure low and high flows: This is required in order to measure lower and high levels of natural gas flows with precision.

- Durability to hazards and environment: Environmental conditions in which flow sensors must reliably function.

- Compatibility to the size: Specific consideration should be taken regarding the suitability of every flow-meter component to the implemented – small or large – place.

- Dirty or Wet Gas: Many measurement devices, especially those with moving parts, struggle to maintain accuracy in conditions where the gas is not pure.

- Exact Calibration and Maintenance: Many flow meters need regular calibration to ensure accurate readings. Over time, components can wear out, affecting the measurement accuracy. Regular maintenance is crucial but can be costly and time-consuming.

How Does a Natural Gas Flow Meter Work?

Natural gas flow meters measure the amount of gas flowing through a pipeline. The working principle involves detecting the gas flow and converting this information into readable data, often via electronic signals. The meters use various technologies to achieve this, each with its unique detection and measurement method.

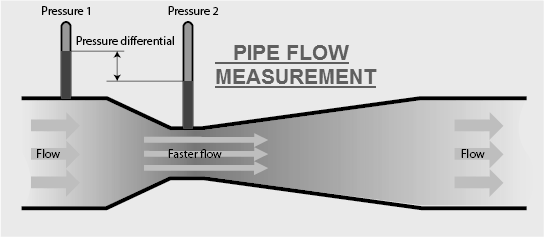

For instance, some meters measure the pressure differential across a constriction, while others detect the speed of gas flow using mechanical or ultrasonic sensors. The choice of technology depends on the application’s specific requirements, such as the range of flow rates, accuracy needed, and the physical properties of the gas.

Flow meters usually measure mass or volume. The flow – denoted ‘Q’ – equals to the cross-sectional area of the pipe – denoted ‘A’ – within a volumetric flow meter as well as the velocity of the flowing fluid – denoted ‘v.’

i.e. Q = A*v

The mass flow can easily be expressed within a mass flow meter as follows:

m = Q*ρ (where Q is the volumetric flow rate and ρ refers to the fluid density).

In many cases, the key consideration is the mass flow rate, especially in chemical reactions, combustion, or selling and buying gases.

More about: Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

Featured Digital Natural Gas Flow Meters

Comparative assessment of different Operative Techniques for Natural Gas Flow Measurement

The challenge with natural gas measurement stems from its fluid nature—it’s not a solid or liquid but a gas, which can vary in density, pressure, and temperature. Below are some common technologies used for accurate “natural gas measurement”.

| Technique name | Features | Pros | Cons |

| Orifice Meters | Orifice meters are one of the oldest and most widely used methods for measuring the flow rate of natural gas. They function by introducing a restriction (the orifice plate) into the pipeline. This restriction causes a pressure drop that can be measured, and the difference in pressure before and after the orifice plate can be used to calculate the flow rate of the gas. | Uncomplicated design, relatively low cost, and well-understood technology | Erogenous to dirt and debris in the gas stream, requires periodic calibration. |

| Turbine Flow Meters | A turbine flow meter utilizes a mechanical rotor attached to a shaft within a pipe, which is used in measuring the volume of natural gas. | High accuracy, particularly at high flow rates; robust and serviceable | Moving parts need maintenance; not appropriate for low-flow or dirty gas conditions. |

| Vortex Flow Meters | Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. As fluid moves across a vortex meter shedder bar, vortices form. The frequency of the vortices shedding is proportional to the fluid velocity. | No moving parts, low maintenance cost, high accuracy | May be affected by pipe vibration. |

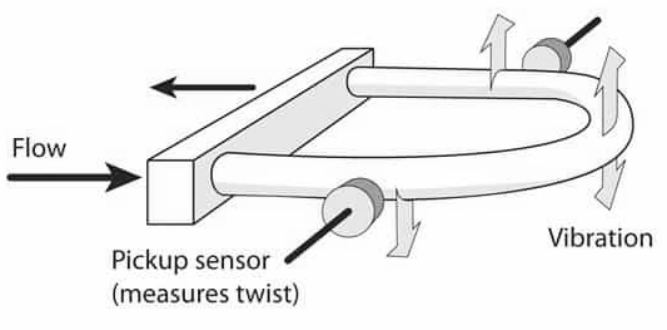

| Coriolis Flow Meters | Erogenous to dirt and debris in the gas stream, it requires periodic calibration. | Coriolis mass flow meter is a mass flow meter based on the Coriolis force. Coriolis mass flow meter can measure different values at the same time. Mass, volume flow, density, and concentration measurement of liquids and gases. | Real mass flow measurement, Immune to pressure, temperature, and viscosity, inlet and outlet sections required. |

| Differential Pressure (DP) Flow Meters | Requires an induced pressure drop for an operation that could be avoided using other techniques, prone to wear over time. | Environmental vibrations cause inaccuracies in measurement and a high cost. | No moving parts, High-fidelity measurements, Trustworthy operation, widely used. |

| Thermal Gas Flow Meter | Could measure mass flow or standard volume flow rate of gas. Range ratio 100:1, could measure gas flow from 100Nm/s to 0.1Nm/s, and be used for gas leak detection. | No need for Temperature and pressure compensation. | It cannot measure the flow rate of moist gas or liquid. |

Other flow meter types include:

- Electromagnetic flow meters

- Ultrasonic flow meters

- Positive displacement flow meters

- Floating element flow meter

Read more about gas flow measurement and the Role of Temperature and Pressure in Gas Flow Measurement:

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

- What Is Temperature Compensation and Pressure Compensation for Flow Meters?

Advanced Technologies and Innovations

- Smart Flow Meters: With the emergence of the Internet of Things (IoT), smart flow meters are becoming more and more common. These meters are connected to central data systems, allowing for real-time monitoring and diagnostics. They can send alerts if there is a problem, such as a drop in pressure or a deviation from expected flow rates.

- Energy Flow Meters: Instead of measuring just the volume or mass of gas, energy flow meters also measure the energy content of the gas. This is particularly important when different types of natural gas (with varying calorific values) are being transported.

- Non-Intrusive Measurement Techniques: Technologies like clamp-on ultrasonic meters and laser-based measurement systems are instances of this trend. These techniques are particularly useful for retrofitting older pipelines with modern measurement technologies.

FAQ

More Featured Gas Flow Measurement Solutions

- Industrial Nitrogen Gas Flow Meters

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Featured Gas Turbine Flow Meter for Natural Gas and Other Gases

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

- Case Study: Custom Thermal Mass Flow Meter For Nitrogen Flow Measurement

In the end, we can surely say that achieving accurate “natural gas measurement” is indispensable for a well-functioning, safe, and efficient natural gas distribution system. As technology advances, the industry is set to overcome challenges, providing ever more precise and reliable data for stakeholders across the energy supply chain.

Sino-Inst has provided gas flow measurement solutions for users in various industries for many years. Including natural gas, nitrogen, compressed air, etc. If you need to purchase a natural gas flow meter, or have related technical questions, please feel free to contact our engineers!

-1.jpg)