The ultrasonic fuel level sensor is an externally attached oil level measuring sensor. It is used to measure the height of the liquid level in the fuel tank, tank and container. It is also widely used as an oil level monitoring device in fleet management.

The ultrasonic fuel level sensor uses the principle of ultrasonic detection to detect the fuel level of the fuel tank. The liquid level signal can be sent to the system platform via GPS. The fuel volume data is transmitted to the background monitoring system to achieve real-time monitoring of vehicle fuel consumption.

Features

High precision.

The oil level sensor has an oil level height measurement resolution of 0.1mm and a measurement accuracy of ±0.5%. It can ensure high measurement accuracy in high temperature and cold external environments;

Good long-term stability.

The oil level sensor adopts ultrasonic measurement method and implements non-contact measurement. It is different from the currently commonly used direct contact float, pressure and magnetic sliding measurement methods. This prevents the oil level sensor from being corroded and contaminated by fuel and maintains long-term measurement stability;

Easy to install and maintain.

Simply install the sensor probe underneath the outside of the tank. No changes to the original tank measurement system are required. No drilling and changes to the tank are required. And it can ensure the normal operation of the original car fuel gauge;

Environmentally friendly, pollution-free, low energy consumption, non-contact measurement. There is no need to drill holes or modify the fuel tank to cause fuel dirt and pollution.

Strong reliability.

It can still work normally in harsh environments, is moisture-proof, acid-proof, flame-retardant, anti-interference, and intelligent.

The product can also be used with GPS devices to transmit data to the background through the GPS device. Carry out data statistics, report analysis and query.

Ultrasonic Fuel Level Sensor technical parameters

| Parameters | Specifications | Remarks |

| Working voltage | DC9~36V/DC 5V | – |

| Working current | ≤25mA | If the power supply is high,the current is small. |

| Measurement range | 5~150cm~500cm | Container thickness≤2cm I、Ⅱ、 |

| Measurement accuracy | ≤5mm | I、Ⅱ、 |

| Measurement resolution | 0.1mm | – |

| Explosion proof grade | EXIAⅡCT6 & EXDⅡ CT5 | – |

| Ingress protection | IP67 | – |

| Working temperature | -20℃~60℃ | – |

| Storage temperature | -25℃~70℃ | – |

| Interface | RS232/RS485/0~5V analog | Ⅲ、 |

| Interface parameters | 9600bit/s | Adjustable |

| Thick wall of the container | ≤20mm | I、Ⅱ |

Ⅰ、At room temperature and humidity, 1 standard atmospheric pressure, measuring liquid 0# diesel, detect other liquids, ordering needs to be specified.

Ⅱ、The sensor can meet the 2cm thickness container, 5m range, and the measurement range needs to be informed in advance. By default, 5cm~1.5m.

Ⅲ、The sensor is automatically output mode by default under the RS232/RS485 communication protocol, which is compatible with the MODBUS protocol and the capacitive fuel rod mode.

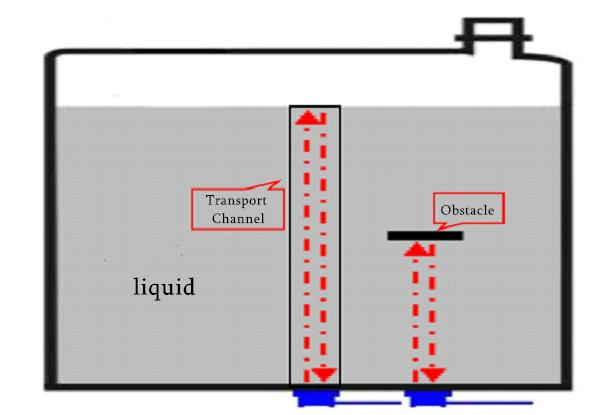

External Paste Ultrasonic Fuel Level Sensor working principle

The ultrasonic fuel level sensor is installed at the bottom of the tank. Applying the echo ranging principle of ultrasonic waves, the ultrasonic signal is sent out from the bottom. The sound wave reflects back after encountering the oil surface, and then calculates the liquid level height according to the time and velocity formula.

At the same time, combined with digital signal processing technology, the influence of container wall thickness can be overcome to achieve high-precision and non-perforated measurement of the liquid level in the container, which can meet the industrial application requirements.

External Paste Ultrasonic Fuel Level Sensor Application

This ultrasonic oil level sensor can be used for various vehicles (such as logistics vehicles, taxis, buses, passenger vehicles, etc.). It is used to digitally record vehicle refueling and fuel consumption, prevent fuel theft, avoid resource waste, improve operational efficiency, improve traffic safety, and strengthen operational management levels.

In addition, this simple ultrasonic level sensor is also used to measure the level of other pure liquids. Such as water, diesel, chemical liquids, etc.

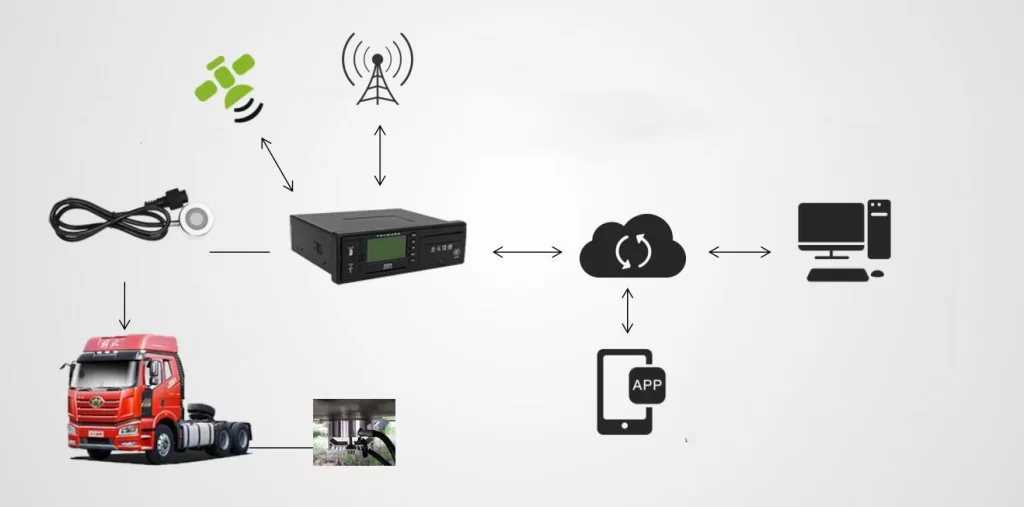

Truck Fuel Tank Level Monitoring System

- The sensor is installed at the bottom of the truck’s fuel tank.

- The truck terminal integrates GSM wireless communication technology and GPS system positioning technology to receive base station signals and satellite signals;

- The terminal uploads positioning information to the monitoring platform through GPRS at the time set by the user.

- The cloud platform receives the reported data:

- Vehicle Information

- GPS terminal information

- Reporting time

- Quantity of refueling

- location information

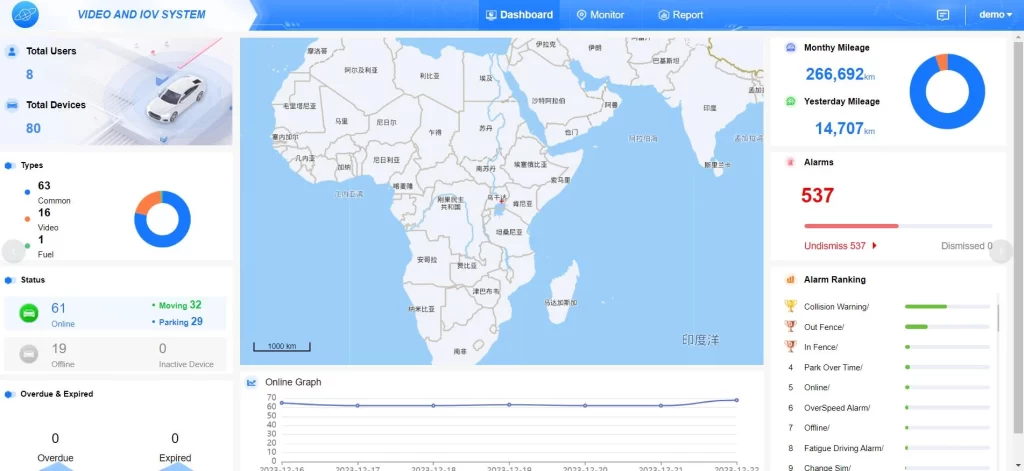

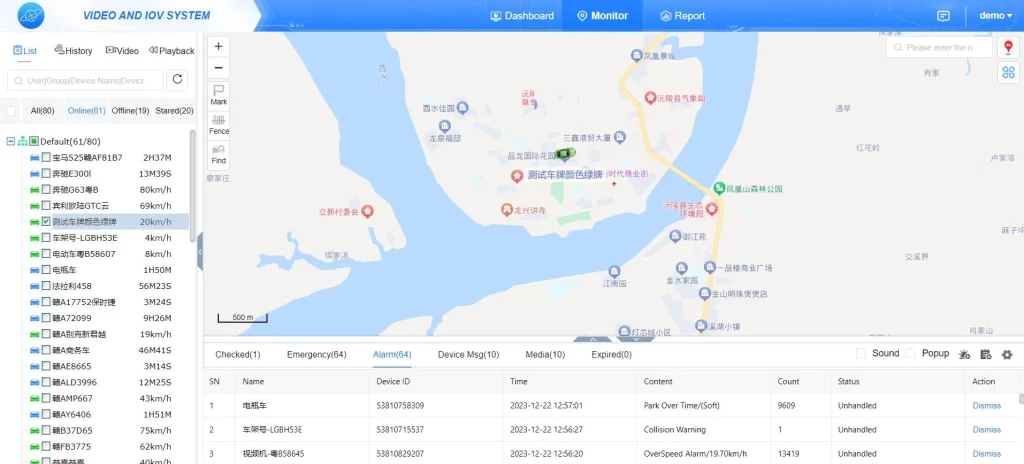

- The platform provides location query, historical location, and real-time fuel level of vehicles at set time points on the map;

- The platform receives status information and alarm information of all vehicles.

- Refueling amount reminder on the client: Generate reports and check and remind the refueling amount on PC/APP;

- Check the refueling volume at the gas station: The platform reminds the driver of the refueling volume to check whether the refueling volume at the gas station is fraudulent;

- Mobile phones can use text message commands to query the real-time location of the vehicle and receive alarm information. Smartphones can install the client to find the location and play back historical tracks.

- The mobile phone can check the set time point location, historical location, alarm information, vehicle fuel information, etc. by installing the client.

More Featured Level Measurement

The ultrasonic fuel level sensor uses an ultrasonic probe to detect the fuel level. High-frequency ultrasonic detection has strong penetration and will not damage the fuel tank. The measuring range can reach up to 5m, no customization is required, and there is no need to choose a fuel tank. Two output interfaces, RS232/RS485, can be configured.

The ultrasonic fuel level sensor is used in fleet management. The sensor uses an ultrasonic probe to detect the fuel level, and then intelligently processes the fuel level signal through the host’s built-in program. Finally, the fuel level information is sent to the system platform through GPS, and is generated after analysis. Oil quantity report.

Sino-Inst offers more than 10 ultrasonic tank level sensors for liquid level measurement. About 50% of these are fuel level gauges and 40% are fuel tank level sensors. You can choose from a wide range of ultrasonic tank level sensors for liquid level measurement, such as free samples, paid samples.

If you need to purchase ultrasonic fuel level sensor or have related technical questions, please feel free to contact us.

Ultrasonic Fuel Level Sensor-External Paste-Truck Fuel Tank

The ultrasonic fuel level sensor is an externally attached oil level measuring sensor. It is used to measure the height of the liquid level in the fuel tank, tank and container. It is also widely used as an oil level monitoring device in fleet management.

Product SKU: Ultrasonic Fuel Level Sensor-External Paste-Truck Fuel Tank

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 149

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)