Ultrasonic water flow meter is an ultrasonic flowmeter for measuring various water flow rates.

Ultrasonic flow meters are based on the speed at which ultrasonic waves are transmitted by a flowing medium. A flowmeter developed by the sum of the average velocity of the measured medium. And the vector of sound waves moving in a stationary medium. Ultrasonic flow meters are non-intrusive flow meters. Ultrasonic water flow meters use sound vibrations to measure liquid flow rates. There are two types of ultrasonic flow meters, Doppler and transit time. Ultrasonic meters are ideal for wastewater treatment or any conductive or water-based dirty liquid.

Features of Ultrasonic flow meter

General ultrasonic flow meters are based on the speed at which ultrasonic waves are transmitted by a flowing medium. A flowmeter developed by the sum of the average velocity of the measured medium and the vector of sound waves moving in a stationary medium. There are many types of ultrasonic flow meters. For example, beam moving method, speed difference method, Doppler method, noise method and correlation method.

The ultrasonic flowmeter has the following characteristics:

- Ordinary ultrasonic flow meters can be used for non-contact measurement. The clip-on converter ultrasonic flowmeter can be installed without stopping as long as the converter is installed outside the existing pipeline. In general, this is a unique advantage of industrial flow meters and is therefore mobile. This means that non-fixed installation measurements may be suitable for pipe network flow condition assessment measurements.

- Ultrasonic flowmeter is suitable for large circular pipes and rectangular pipes. There is in principle no restriction on the diameter. If actual traffic verification is not possible, it can be considered one of the preferred options.

- Non-flow interference measurement of ultrasonic flowmeter without additional pressure loss;

- Ultrasonic flowmeter measures non-conductive liquid, supplementary ultrasonic flowmeter does not interfere with flow measurement.

- The external clip converter ultrasonic flowmeter cannot be used for pipelines with thick lining or thick scale. Nor can it be used for lining (or rust layer) and inner wall peeling (when there is gas in the core clamp, the ultrasonic signal will be seriously attenuated) or the corroded pipe (the ultrasonic propagation path has been changed).

- The radio time method ultrasonic flowmeter can only be used to clean liquids and gases;

- Some ultrasonic time flowmeters have the function of measuring the propagation time of sound waves. It is therefore possible to measure the speed of liquid sound. For example, when a tanker is transporting oil by drift, it can be determined whether the measurement is petroleum or warehouse bottom water.

This is the main feature of the ultrasonic flowmeter.

How does an ultrasonic flow meter work?

Ultrasonic Flow Meter Formula

When the ultrasonic beam propagates in a liquid, the flow of the liquid will cause a small change in the propagation time. And the change in the propagation time is proportional to the flow velocity of the liquid. The relationship is as follows:

![]()

Which

θ is the angle between the sound beam and the direction of liquid flow.

M is the number of linear propagations of the sound beam in the liquid.

D is the inner diameter of the pipe.

Tup is the propagation time of the sound beam in the positive direction.

Tdown is the propagation time of the sound beam in the reverse direction.

ΔT = Tup –Tdown

Let the speed of sound in a stationary fluid be c. The velocity of the fluid flow be u. And the propagation distance be L.

When the sound wave is in the same direction as the fluid flow (that is, in the downstream direction), its propagation velocity is c + u.

Otherwise, the propagation velocity is cu .

Place two sets of ultrasonic generators and receivers (T1, R1) and (T2, R2) at two places separated by L.

When T1 transmits ultrasonic waves in the forward direction and T2 in the reverse direction.

The time required for the ultrasonic waves to reach the receivers R1 and R2 is t1 and t2, then:

t1 = L / (c + u); t2 = L / (c-u)

Because in industrial pipelines, the velocity of the fluid is much smaller than the speed of sound, that is, c >> u, the time difference between the two is ▽ t = t2-t1 = 2Lu / cc.

It can be seen that when the sound wave propagates in the fluid c When known, the flow velocity u can be obtained by measuring the time difference ▽ t, and the flow rate Q can be obtained.

The method of flow measurement using this principle is called the time difference method. In addition, phase difference method and frequency difference method can be used.

Portable ultrasonic water flow meter

| Diameter | DN15~ DN6000 | Data Record | Thermal printer,external SD card (2G of capacity) |

| Accuracy | ±1% | Flow rate | 0~±10m/s |

| Temp. range | -30~160°C | Liquid type | hot water, chilled water, city water, sea water, waste water, Sewage with small particle content;crude oil, lubricating oil, diesel oil, fuel oil, Chemicals (alcohol, etc. ) ; Plant effluent; Beverage; Ultra-pure liquids, etc. |

Clamp on Ultrasonic Water Flow Meter

SI-3403 Clamp on Ultrasonic Flow Meter, also called the wall mounted ultrasonic flow meter. With the remote mount transmitter, SI-3403 Clamp on Ultrasonic Flow Meter, could be applied to a variety of liquid applications.

Including: Water, chemicals, raw sewage, reclaimed water, cooling water. River water, plant effluent, alchole, beer, etc.

| Diameter | DN32~6000 | Protection | Host: IP67; flow sensor:IP68 |

| Accuracy | ±1% | Flow rate | 0~±7m/s,Forward and backward measurement |

| Temp. range | -30~160℃ | Liquid type | water,sea water ,alcohol,Acid and alkali,waste water,beer,all kinds of oil Single liquid can transmit sound wave. |

Handheld Ultrasonic Water Flow Meter

SI-3401 Handheld ultrasonic flowmeter is a patrol-type flow measuring instrument.

The sensor has only one clamp on type, which realizes non-contact measurement.

The sensor is installed on the outer wall of the pipeline to complete the measurement of the flow.

It has small volume and convenient carrying. Measure accurate features.

| Diameter | DN32~DN6000 | Special Cable | Twisted-pair cable, under 50 m; RS485,transmission distance can over 1000m |

| Accuracy | ±1% | Liquid type | Such as Water (hot water,sea water, waste water, etc.); Oil(crude oil, diesel fuel oil etc.) etc. |

| Temp. range | -30~160℃ |

Ultrasonic Water Flow Meter Price

Sino-Inst is the manufacturer of Ultrasonic water flow meter. Sino-Inst offers technical support and best price for our customer.

Before ordering, the following questions must be considered. With answers to the following questions we can select the appropriate flow device and ship it to your location.

What are the pipe sizes of the liquids that are going to be measured?

What is the minimum and maximum process temperature of the application?

Do you require a portable battery operated unit or a permanent fixed flow monitor powered by mains?

What are the output requirements? E.g. analog, digital, pulse?

What is the minimum and maximum flow rate for the flow meter?

What is the minimum and maximum flow velocity?

Is there a length of straight pipe away from bends and pipe disturbances?

Is the pipe always filled with liquid?

The reference price of Ultrasonic water flow meter is USD300-700

Q&A

The ultrasonic flowmeter provided by Sino-Inst has a universal accuracy of ± 1%. If customers want more accurate ultrasonic flow meters, Sino-Inst supports customization.

How to make use of the measurement accuracy of ultrasonic flowmeters?

First of all. An ultrasonic flowmeter is a velocity flowmeter that measures the flow velocity of a fluid in a pipe. For how to improve the accuracy of the ultrasonic flow meter at this point. The first is that the fluid flow in the pipe is constant. Fluid flow is constant. Only the flow rate measured by an ultrasonic flow meter is a flow rate close to the actual flow rate. This will allow accurate measurements.

The point is. To ensure the accuracy of ultrasonic flow meters, you must ensure that:

1.Enough straight tubes,

2, and the liquid flow rate is usually less than 15 m / s,

3. The dirt on the inner wall of the pipeline should be as small as possible.

4. The noise around the selected measuring point and frequency conversion interference (some products have no signal of frequency conversion interference).

5, so that there are no two flows of media, the specific cleaning of the outer surface of the measurement point

6. Of course, the most important thing is to choose the right flow meter.

History of ultrasonic flowmeters

(1) In 1928, the Germans developed the first ultrasonic flowmeter and obtained a patent. Ultrasonic flowmeters have a history of 80 years.

(2) In 1955, it was first applied to the MAXSON flowmeter to measure aviation combustion oil. This is a liquid flow meter composed of two sets of probes (transducers) based on the acoustic circulation method

(3) A.L.H-ERDRICH et al. Invented the refractive probe in 1958. Because their research can further eliminate the phase distortion caused by the reverberation of the pipe wall, it also provides a theoretical basis for the external clamping of the pipe. Since the 1970s, due to the development of integrated circuits and phase-locked loop technology, ultrasonic flowmeters have overcome the fatal weaknesses of low accuracy, slow response, and poor stability and reliability. The practical ultrasonic flowmeter was developed.

In the past 20 years, especially in the past 10 years, the rapid development of high-speed digital signal processing technology and micro-processing technology. Based on the research of new probe materials and processes and the study of channel configuration and flow dynamics, ultrasonic flow measurement technology has made great progress. Shows strong technical advantages and rapid development momentum. A total of 103 academic papers were presented at the International Conference on Flow Measurement (FLOMEK-O‘2000) held in Brazil in 2000. Among them, there are 20 papers directly related to ultrasonic flow meters and ultrasonic technology, accounting for about 1/5 of the total number of papers. At previous international conferences on flow, more and more literatures have adopted ultrasonic flow meters as the transmission standard. It can be seen that the ultrasonic flowmeter has huge potential vitality.

The accuracy of the flowmeter is generally calibrated directly when the factory leaves the factory. Gas flowmeters can generally reach level 1.0, and level 0.5 is already considered highly accurate. The accuracy of liquid flowmeter is generally 0.2% -0.5%. Of course, the accuracy of the flow meter still depends on the site conditions. If the measurement of temperature and pressure is not very difficult, the accuracy of the flow meter is definitely high. In addition, to ensure the accuracy of the flowmeter, it is also very important to install and use it correctly.

Technical Support

Ultrasonic Flow Meter Technology

Ultrasonic flow meters are non-intrusive type liquid flow meters. Ultrasonic flowmeter measures the flow by detecting the effect of fluid flow on an ultrasonic beam (or ultrasonic pulse). There are two types of ultrasonic flow meter technologies: Doppler shift and transit-time.

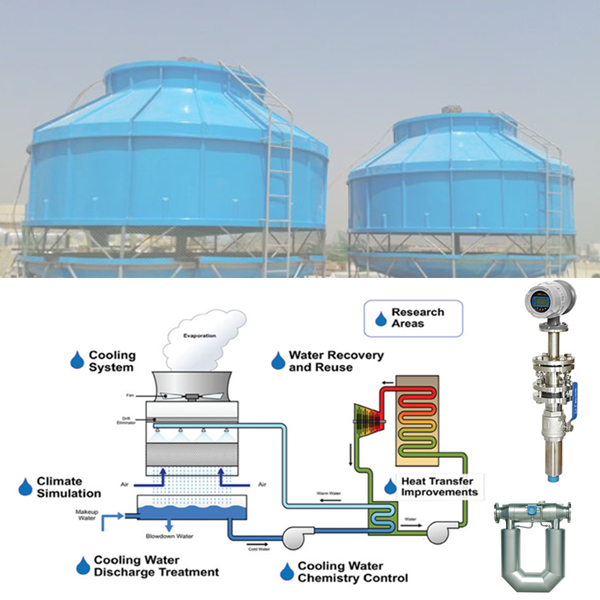

Cooling Water Flow Measurement

The cooling water flow meter is used to measure the cooling water flow rate. Cooling water flow meters are commonly used in cooling water towers, circulation systems, pipes, tanks, and pumps.

Wastewater flow meter

Wastewater Flow meters are flowmeters for water and wastewater treatment. Electromagnetic flow meters are suitable for open channel and underground industrial water pipes. And ultrasonic flow meters are another choice, if you can not change your pipes.

-1.jpg)