A power plant uses lime slurry as a desulfurizer. Gypsum or calcium sulfate is formed by reacting with sulfur dioxide in the flue gas. Thus, the purification and emission control of harmful gases in exhaust gas can be achieved.

Measuring the density (concentration) of lime slurry is to ensure that the appropriate amount of desulfurizer can be accurately added during the desulfurization process. This ensures the desulfurization effect and the stability of equipment operation.

Features of lime slurry

The chemical formula of lime slurry is Ca(OH)2. Commonly known as hydrated lime, it is a white solid, slightly soluble in water, and its aqueous solution is often called lime slurry. Lime slurry is generally produced by adding water to calcium oxide.

Role in modern industrial production:

- Reduce the concentration of the solution to facilitate the decomposition of the seed crystal.

- Further desilicate the sodium aluminate solution.

Importance of lime slurry density measurement

The steel and electric power industries are one of my country’s key industrial fields, but due to the large amounts of waste products such as flue gas and waste water produced during their production processes, environmental pollution problems are more prominent. In order to protect the environment, the industry is also gradually promoting cleaner production, among which flue gas desulfurization and denitrification devices are one of the important environmental protection measures.

Power plants generally use lime slurry as desulfurizer. Gypsum or calcium sulfate is formed by reacting with sulfur dioxide in the flue gas. Thus, the purification and emission control of harmful gases in exhaust gas can be achieved.

Measuring the density (concentration) of lime slurry is to ensure that the appropriate amount of desulfurizer can be accurately added during the desulfurization process, thereby ensuring the desulfurization effect and the stability of equipment operation.

Density is an important parameter to measure the concentration of limestone slurry, which directly affects the efficiency of the desulfurization reaction and the overall performance of the exhaust gas treatment system.

User measurement needs

- Combined with the actual on-site process conditions (gypsum or calcium sulfate precipitation will be formed after the reaction), it cannot cause blockage of the pipeline;

- Able to realize lime slurry density (concentration) measurement function;

- High precision and repeatability ensure consistent product quality;

Our solutions

In this measurement, density is an important parameter to measure the concentration of lime slurry, which directly affects the efficiency of the desulfurization reaction and the overall performance of the exhaust gas treatment system.

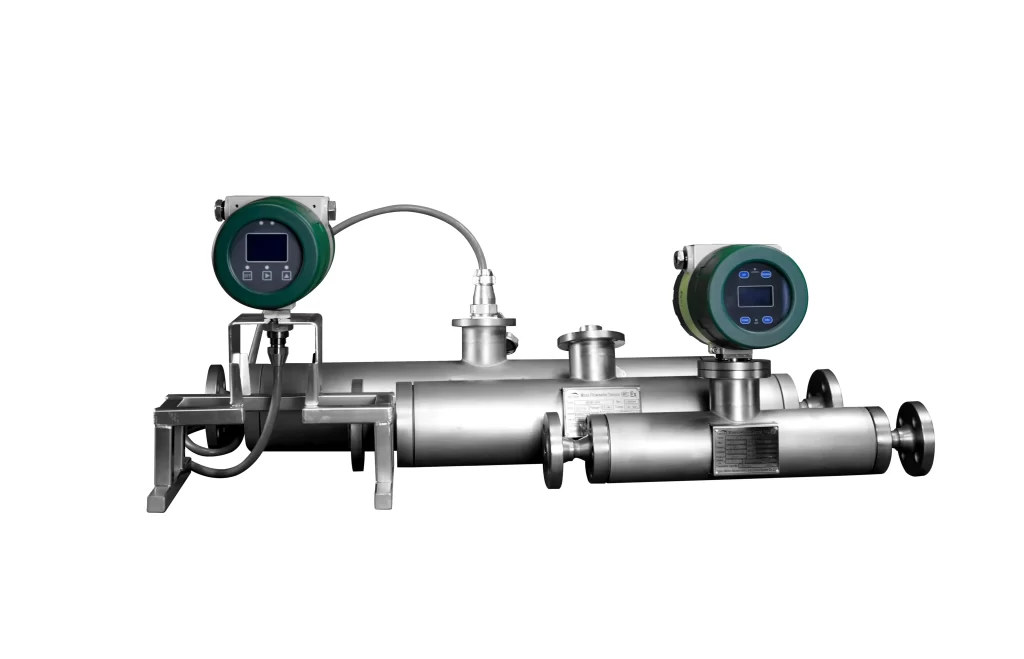

Therefore, we recommend our straight tube series mass flow meter products to customers based on their needs to control the precise measurement of lime slurry density (concentration) during the desulfurization process.

- Compared with the traditional U-shaped (slightly curved) structure, the mass flowmeter with a straight tube structure is less likely to have medium residues, thus solving the problem of “pipe clogging” that customers are worried about;

- Using digital high-frequency technology, the measurement accuracy is greatly improved and the density of limestone slurry is successfully measured accurately;

- The use of “military grade” chips ensures high accuracy and repeatability during the measurement process.

Advantages of straight tube mass flowmeter

| Model | The path | Flow range | Zero stability |

| mm | kg/h | kg/h0.15%0.1% | |

| CMF Z -008Z | 8 | 0~960~1440 | 0.144 |

| CMF Z -010Z | 10 | 0~1500~2250 | 0.225 |

| CMF Z -015Z | 15 | 0~3000~4500 | 0.45 |

| CMF Z -020Z | 20 | 0~6000~9000 | 0.90.780.9 |

| CMF Z -025Z | 25 | 0~9600~14400 | 1.441.351.44 |

| CMF Z -032Z | 32 | 0~18000~27000 | 2.7 |

| CMF Z -040Z | 40 | 0~30000~45000 | 4.5 |

| CMF Z -050Z | 50 | 0~48000~72000 | 7.2 |

Through the Coriolis mass flow meter, it has successfully helped power plant operators better control the density of lime slurry, improving the efficiency of the desulfurization reaction and the overall performance of the exhaust gas treatment system.

Electromagnetic flowmeter measures lime slurry

Of course, if you only need to measure lime slurry traffic. No density measurement is required. Then the measurement can be completed using an electromagnetic flowmeter.

Use an electromagnetic flowmeter to measure lime slurry. The electrodes are platinum electrodes lined with neoprene. Flanges can be used for installation. The power supply can be either 24V or 220V. In this way, the traffic measurement of lime slurry can be easily solved.

More Featured Flow Measurement Solutions

- Guide: Types of Mass Flow Meters

- Fluid Flow Sensor | Types and Product List

- What Is Variable Area Flow Meter?

- Flowmeter Selection Guide | Find the Best One for Your Application

- 11 Flow Meter Types and Their Advantages and Disadvantages

In industries such as steel, electric power, metallurgy, and environmental protection, straight-tube mass flow meters have had many successful cases. Because of their unique “straight-tube” structural characteristics, they are widely used in special scenarios such as “pipelines are prone to blockage”. And has won wide acclaim in many industries.

In summary, using a straight-tube mass flow meter to measure the density of lime slurry is of great significance in the desulfurization process of power plants. By selecting advanced mass flowmeter technology, accurate measurement of medium density can be achieved, providing reliable support for the stable desulfurization reaction, thereby ensuring the normal operation of the power plant’s environmental protection equipment.

If you need lime slurry flow measurement, density detection, etc., please feel free to contact our sales engineers!

-1.jpg)