Hydrogen flow meters are widely used in hydrogen energy fields, such as hydrogen production, hydrogen storage and hydrogen fuel cells. Typically used to monitor volumetric flow, mass flow and usage of hydrogen to ensure proper system operation and optimize performance.

Since the value of hydrogen is very high, custody transfer metering is also a very important feature of hydrogen flow measurement.

Characteristics and industrial applications of hydrogen

Hydrogen (chemical formula H2) is composed of two hydrogen atoms and is colorless, tasteless, odorless, non-toxic and flammable. With a molecular weight of 2 and a specific gravity of 0.0695, hydrogen is considered the lightest gas, more than 14 times lighter than air (mv=28.8).

Hydrogen is very flammable. Under normal pressure, a mixture with a hydrogen content of 4.0% to 74% is flammable. Since the minimum ignition energy of hydrogen (0.02mJ – one order of magnitude smaller than the minimum ignition energy of hydrocarbons) is very small, strict precautions must be taken to prevent leakage.

Hydrogen is a valuable and widely measured industrial gas that plays an important role. Hydrogen has important applications in petrochemical industry, food grain and oil processing, semiconductor electronics industry, fuel cell manufacturing, pharmaceutical chemical industry, power production, etc.

Hydrogen is used in many petroleum refineries to produce petroleum products such as diesel and gasoline. It helps avoid many impurities, such as sulfur, in the final products produced by these refineries.

Different chemical industries require hydrogen to produce important hydrogen-based compounds such as ammonia and methanol.

- Manufacturers of fertilizers and other agricultural products need hydrogen because ammonia is an important component of most fertilizers.

- The manufacture of metal products requires hydrogen for atomic hydrogen welding, an important arc welding equipment.

- Electronic products, such as semiconductors, display screens and LED lights, require hydrogen for the reduction process.

- The glass industry requires hydrogen to prevent oxidation of glass while making final products from flat glass.

- Hydrogen is also needed by the power generation and aviation industries, and the gas can be used as a fuel when supplied through pipelines from hydrogen plants.

- In the metallurgical industry, hydrogen is used as reducing agent and protective gas in the production and processing of non-ferrous metals such as tungsten, molybdenum, and titanium.

- In the aerospace industry, hydrogen is an important fuel. Due to the good combustion performance of hydrogen and the increasingly stringent environmental protection regulations, there is a potential huge demand for hydrogen in the future market.

Since the value of hydrogen is very high, custody transfer metering is a very important feature of hydrogen flow measurement.

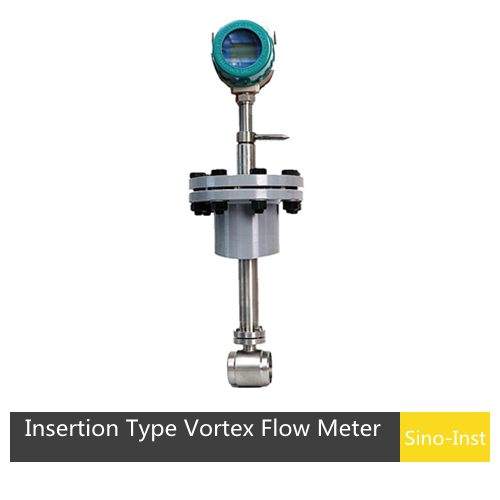

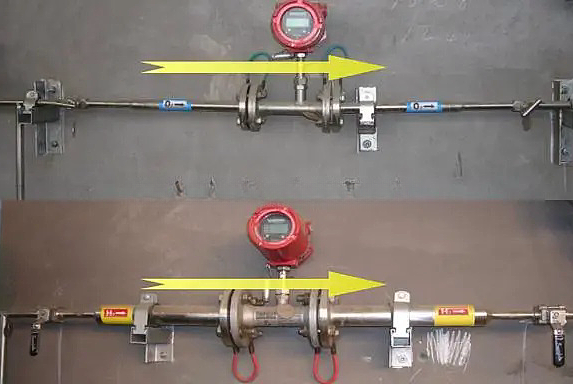

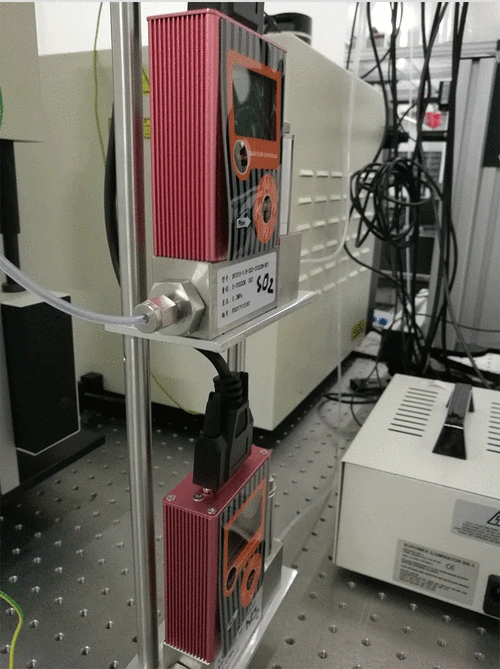

Featured Digital Hydrogen Flow Meters

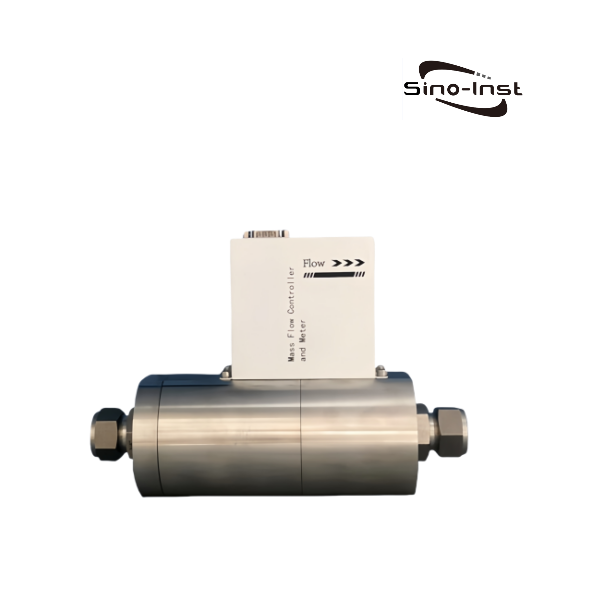

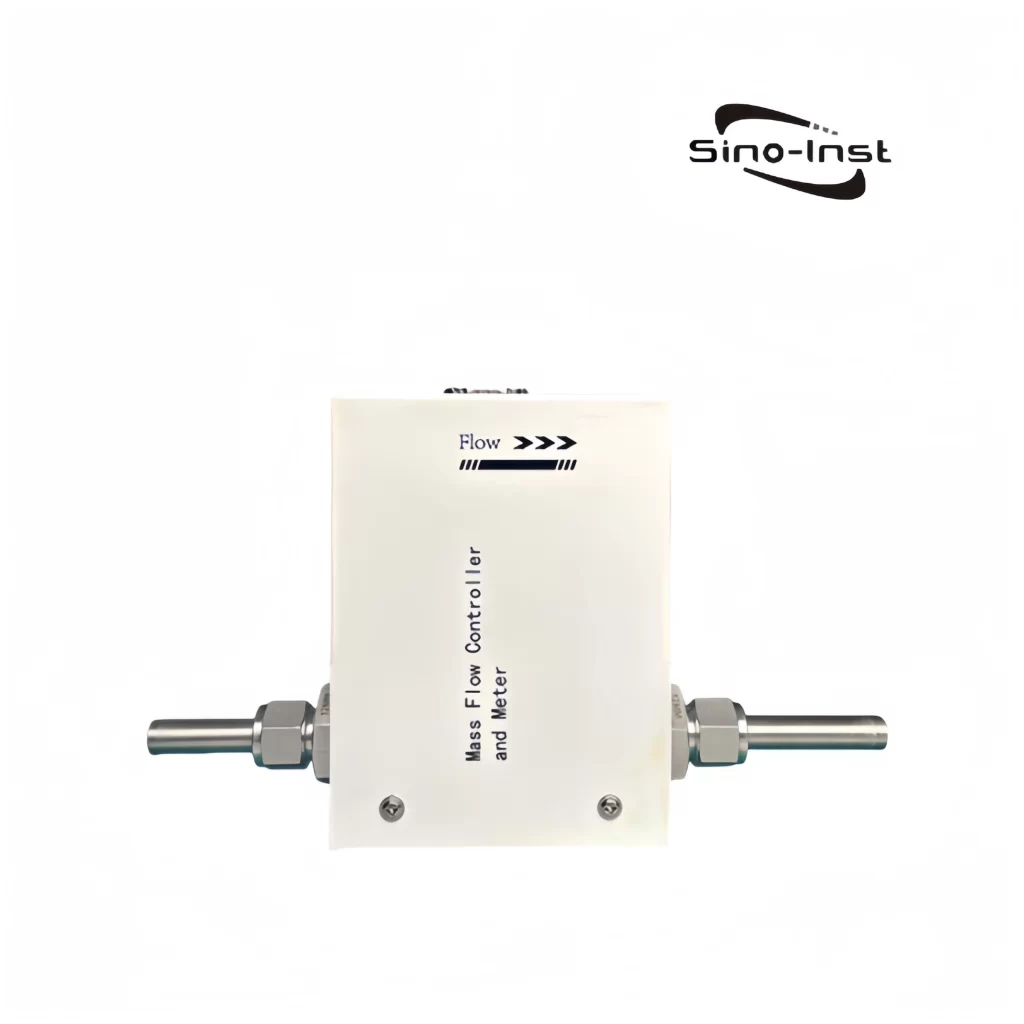

Featured Hydrogen Flow Controllers

Hydrogen mass flow measurement

Depending on the application conditions and budget, either a thermal mass flow meter or a Coriolis mass flow meter can be selected for hydrogen mass flow measurement.

Top Choice: Advanced Thermal Mass Flow Meters

We at Sino-Inst recommend using a thermal gas mass flow meter to measure hydrogen mass flow.

Thermal gas mass flow meter is an instrument that uses the principle of thermal diffusion to measure gas flow. Thermal flow meters have two temperature sensors placed in the medium. One of the sensors is heated to a temperature above ambient temperature. Another temperature sensor is used to sense the medium temperature.

As the flow rate of the medium increases, the heat taken away by the medium increases. The temperature difference between the two temperature sensors will change with the flow rate of the medium. According to the proportional relationship between the temperature difference and the medium flow rate, the flow rate Q of the fluid can be obtained.

Thermal gas mass flowmeter has the characteristics of easy installation, simple maintenance, anti-vibration, large pipe diameter and small flow measurement, no need for temperature and pressure compensation, and wide range ratio. It is a gas flow meter that is widely used in hydrogen flow measurement in the world.

Coriolis Mass Flow Meter for Higher Accuracy

Coriolis mass flow meters can simultaneously measure mass flow rate, density, and temperature. Compared to thermal mass flow meters, Coriolis mass flow meters offer higher accuracy in hydrogen measurement, ranging from 0.1% to 0.2%.

In hydrogen flow measurement applications, Coriolis mass flow meters offer a large range ratio, require no sealing gaskets, and are SIL-certified and explosion-proof, ensuring high safety.

Coriolis mass flow meters have high measurement sensitivity, making them suitable for a wide range of mass flow measurement. They exhibit excellent zero-point stability, enabling hydrogen measurement under low-pressure conditions with minimal measurement error.

Despite their higher cost, Coriolis mass flow meters remain a popular, safe, and efficient dedicated measurement instrument for hydrogen trade, compression, and transportation.

Hydrogen Volume Flow Measurement

In some applications, where only the volumetric flow rate of hydrogen needs to be measured, other types of hydrogen flow meters can be selected, such as V-cone flow meters, balanced flow meters, throttling flow meters, velocity flow meters, and vortex flow meters.

These flow meters each have their own characteristics:

- V-cone flow meter: Highly sensitive to hydrogen and can operate under high pressure, but it is not well-suited to handling impurities in hydrogen and is prone to deformation at high temperatures.

- Balanced flow meter: Considered a more accurate hydrogen flow meter because it can more precisely control the flow of hydrogen.

- Throttling flow meter: Simple structure, easy installation, reliable operation, low cost, abundant experimental data, and no need for actual calibration.

- Velocity flow meter: Output has a definite relationship with flow velocity, but some types (such as gas turbine flow meters) have mechanical rotating parts and high turbine speeds, resulting in high maintenance requirements and their application is gradually decreasing.

- Vortex flow meter: It has a fast response speed, high reliability and high accuracy, but its application effect may not be ideal under certain conditions (such as medium composition, temperature and pressure compensation).

Hydrogen Flow Controller

Sino-Inst supplies dedicated hydrogen mass flow controllers, available in thermal, differential pressure, and Coriolis principle models.

Hydrogen mass flow controllers can regulate mass flow rate and pressure. For example, in electrolyzers, they accurately monitor H2 and O2 flow rates, ensuring precise measurement and control of deionized water even at low flow rates.

Hydrogen mass flow controllers provide precise multivariate flow and pressure measurement and control for hydrogen fuel cell testing systems, supporting manufacturers in optimizing efficiency during testing and production.

From CO2 hydrogenation to electrolyzer validation and pressure swing adsorption systems, Sino-Inst offers customized support and products with multivariate flow and pressure measurement and control capabilities. These controllers also feature digital communication capabilities for easy integration into users’ testing software, helping them scale up and improve their hydrogen processes.

FAQ

More Flow Measurement Solutions

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

- Electronic Flow Meters-Digital Display

- Top Explosion Proof Flow Meters for Explosive or Hazardous Areas

- Flowmeter Selection Guide | Find the Best One for Your Application

- 11 Flow Meter Types and Their Advantages and Disadvantages

- Top Guide to CO2 Flow Meters

When measuring the flow of hydrogen, when selecting Hydrogen Flow Meters, you can choose the appropriate one based on the measurement medium, operating temperature, rated pressure, nominal diameter, flow range and signal output. You can also consider the parameters provided by the user on site and the user’s cost. Hydrogen Flow Meters model specifications.

Sino-Inst’s Hydrogen Flow Meters provide more accurate and stable measurements. If you need to purchase Hydrogen Flow Meters, or have related technical questions, please contact our engineers!

-1.jpg)