At the core, a ‘Digital Fuel Flow Meter’ is a device used to measure the amount of fuel flowing through a system. It provides valuable data on fuel consumption rates, which can be used to analyze efficiency, monitor fuel costs, and detect anomalies or inefficiencies within a fuel system.

There are several types of flow meters, including mechanical, thermal, ultrasonic, and electromagnetic, but in modern industrial setups, ‘digital fuel flow meters’ have become increasingly popular due to their precision, reliability, and ease of integration with data management systems. Digital flow meters offer an edge by providing real-time monitoring and data logging, which are crucial for performance optimization and regulatory compliance.

What are Digital Fuel Flow Meters?

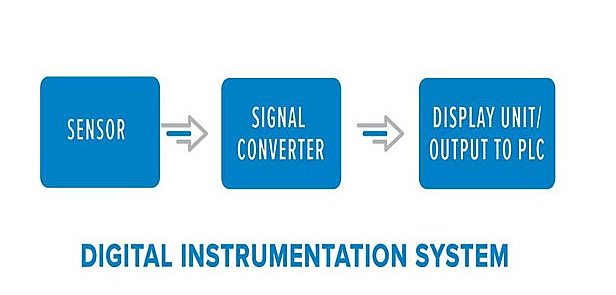

Purpose: Mainly used to control and monitor liquid or gas flow. It uses sensors to convert raw signals into digital signals, then processes the data through a processor, and finally outputs a flow signal. It has great advantages over traditional mechanical flow meters.

Unlike traditional mechanical meters, digital meters provide highly accurate readings and are less prone to wear and tear, making them ideal for high-precision applications in industries such as aviation, shipping, and power generation.

Key Characteristics of Digital Fuel Flow Meters

- Broad Preciseness

- Real-Time Observation

- Data Logging and Reasoning

- Enduringness and Longevity

- Integration with Control Systems

- Environmental Conformation

Applications of Digital Fuel Flow Meters

Digital fuel flow meters are used across a wide range of industries, where fuel efficiency and precision are critical to operations. Some of the major applications include:

Fuel Oil Flow Meters: A Captious Subset

While digital fuel flow meters can handle a variety of fuel types, ‘fuel oil flow meters’ are mostly designed to measure the flow of liquid fuel oils, such as diesel, kerosene, or bunker fuel. These meters are indispensable in applications where fuel oils are used as a primary energy source.

Fuel oil flow meters typically operate using one of several measuring principles:

- Positive Displacement (PD) Meters: A ‘PD’ or positive displacement flow meter measures the fluid in discrete volumes. The fluid flows into a chamber, is sealed off once the chamber is full and produces either an electronic pulse or a drives a gear to register the volume as it exits the chamber.

- Coriolis Flow Meters: A Coriolis meter is founded on the principles of motion mechanics. When the process fluid enters the sensor, it is split. During action, a drive coil stimulates the tubes to oscillate in opposition at the natural resonant frequency. As the tubes oscillate, the voltage generated from each pickoff creates a sine wave.

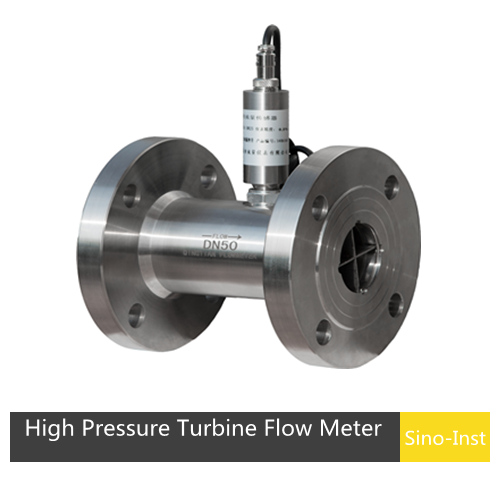

- Turbine Flow Meters: The higher the flow rate, the quicker the turbine blades rotate. The rotation of the turbine blades is based on the principle of conservation of momentum, in which the kinetic energy of the fluid is converted into mechanical energy.

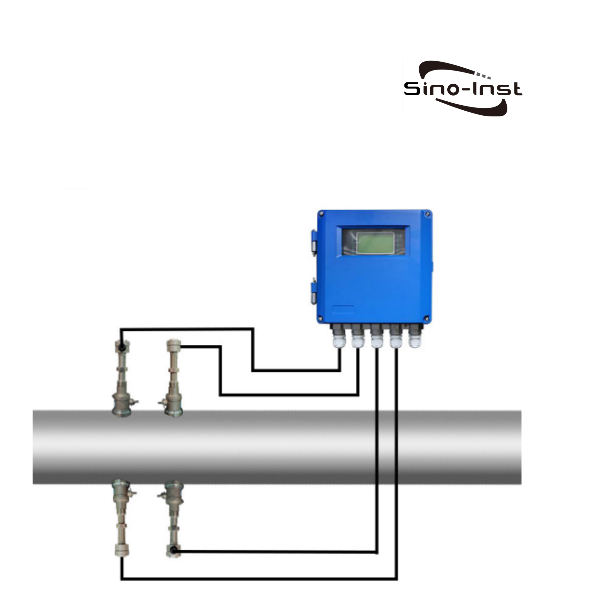

- Ultrasonic Flow Meters: Ultrasonic flow meters work based on the principle of ‘transit time’ or ‘time of flight. ‘ This involves transmitting ultrasonic sound wave from one transducer to another through the fluid in the pipe. Depending on the flow direction, the pulse will either speed up or slow down.

Why Fuel Oil Flow Meters Matter?

1.Maintenance Provision: By accurately measuring fuel oil consumption, industries can reduce the risk of unexpected breakdowns and downtime.

- Fuel Cost Management: Precise fuel oil flow meters help industries monitor their fuel consumption, thus optimizing operations and reducing costs.

- Environmental Consequence: As with other types of fuel, burning fuel oil can have important environmental implications. Fuel oil flow meters permit companies to monitor their fuel consumption and ensure they are operating within environmentally acceptable limits, thus reducing their carbon footprint.

- Functional Efficiency: In industries where fuel oil is used to power generators or machinery, fuel oil flow meters help operators maintain optimal efficiency. This is particularly important in industries such as power generation, where inefficiencies in fuel consumption can lead to significant losses.

- Regulatory Abidance: Accurate fuel oil flow meters enable companies to meet regulatory requirements by providing precise data on fuel consumption and emissions levels.

Benefits of Implementing Digital Fuel Flow Meters and Fuel Oil Flow Meters

- Enhanced Accuracy

- Improved Operational Efficiency

- Better Decision Making

- Sustainability and Environmental Compliance

- Lower Maintenance Costs

Most featured Digital and oil flow meter solutions available in Sino-Inst:

- Mechanical Oil Flow Meter vs Digital

- How to Choose the Right Heating Oil Flow Meter for Your Business

- Top 3 Flow Meters for Oil

- How to Choose the Right Oil Pressure Transmitter for Your Application

- Industrial Oil Flow Meters

- High-Performance Marine Fuel Flow Meters | Save Your Costs!

- Industrial Fuel Flow Meters – Choose the Right one for You

- Diesel Flow Meter

Both ‘digital fuel flow meters’ and ‘fuel oil flow meters’ have become indispensable tools in modern industry. Their ability to provide accurate, real-time measurements of fuel consumption allows industries to optimize their operations, reduce costs, and abide by with environmental regulations. With the increasing focus on sustainability and efficiency, the demand for these advanced flow meters is only expected to grow.

In a world where fuel costs continue to rise and environmental concerns become more pressing, industries embracing these technologies will be in better trajectory towards success. This will not only guarantee their profitability but also their obligation towards the planet.

Sino-Inst has been providing high-quality fuel measurement solutions to users in various countries for many years. If you have any technical questions, please feel free to contact our sales engineers!

-1.jpg)