Air is a clean, efficient, and readily available energy source that plays a vital role in many industrial sectors, such as compressed air. In some operating conditions, we also need to monitor the emission of hot air.

Sino-Inst offers the following monitoring services for air and compressed air: air pressure monitoring, air temperature monitoring, and air flow monitoring.

Industrial Air Applications

Air plays a wide and crucial role in industrial production. It serves not only as a power source for various mechanical equipment and control systems but also in processes such as purging, cleaning, spraying, and sandblasting. With continuous technological advancements, the application areas of compressed air will continue to expand and improve, bringing even greater convenience and benefits to industrial production.

Driving Mechanical Equipment:

Compressed air is widely used to drive various pneumatic tools, pneumatic clamps, cylinders, and other equipment. These devices play a key role in industrial production lines, such as assembly lines and packaging lines, where the application of compressed air significantly improves production efficiency.

Pneumatic Control Systems:

Compressed air is also used to control pneumatic control systems, such as the opening and closing of pneumatic valves and the operation of pneumatic motors. This control method offers advantages such as fast response and high control precision, and is widely used in industrial scenarios requiring precise control.

Machinery Cleaning:

During the manufacturing process, air compressors can provide high-speed compressed air to purge and clean dust, dirt, and other impurities from the surfaces of machines, equipment, and parts, thereby improving product quality and production efficiency.

Pipeline System Purging:

During the installation and maintenance of pipeline systems, compressed air is also used to purge the interior of the pipelines, removing residues and impurities to ensure unobstructed flow.

Surface Coating:

In industries such as construction and automotive, compressed air is used for spraying operations. Compressed air atomizes paint and sprays it onto the workpiece surface, forming a uniform coating that improves the product’s appearance and corrosion resistance.

Sandblasting and Rust Removal:

In metal surface treatment, compressed air is mixed with abrasive particles to form a high-speed jet stream used to remove rust, scale, and other contaminants from metal surfaces, preparing them for subsequent coating or processing steps.

Gas Separation:

In some industrial production processes, such as the separation of petroleum cracking gas, compressed air is used to compress gases and separate components at different temperatures to obtain gases of suitable purity.

Chemical Reactions:

In the chemical industry, compressed air is also used in certain chemical reaction processes, such as synthesis and polymerization reactions. Compressed air provides the necessary pressure and oxygen environment to promote the reaction.

Air Cushion Suspension:

In the logistics industry, compressed air is used to create air cushions, suspending objects in the air for transportation and handling of large goods. This method reduces frictional resistance between the object and the ground, lowers energy consumption, and improves transportation efficiency.

Besides the air applications mentioned above, we also need to monitor air quality in some air emission scenarios.

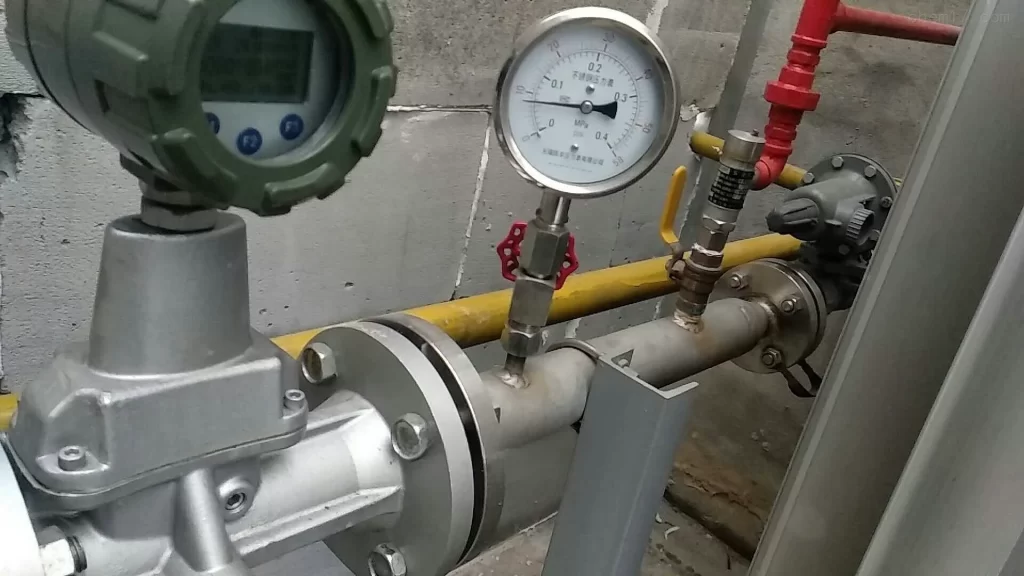

Air Pressure Monitoring

In industrial processes, pressure gauges, pressure sensors, or pressure transmitters are commonly used to monitor the pressure in air pipelines or tanks. Pressure gauges are mechanical. Pressure sensors and pressure transmitters are intelligent products with higher measurement accuracy. Furthermore, pressure transmitters can display and output signals of air pressure values in real time, such as 4-20mA, RS485, and HART.

For industrial use of air, compressed air, and high-temperature air, Sino-Inst supplies various types of high-quality pressure transmitters. These measure gauge pressure, absolute pressure, and differential pressure, including:

- High-pressure air transmitters

- High-temperature air transmitters

- High-frequency dynamic pressure transmitters

- Integrated temperature and pressure transmitters

- Intelligent Pressure Transmitter

Read more about:

- Pressure Transmitter 4-20mA Guide: Testing and Troubleshooting

- Pressure Switch vs Sensor What You Need to Know

- Gas Pressure Measurement for Industrial Tanks and Pipelines

- Common Industrial Pressure Measuring Devices

- Understanding Digital Air Pressure Sensors: Why They Matter

- Negative Pressure-Vacuum Flow Meters

- 2 Wire-3 Wire-4 Wire Pressure Transducer Wiring Diagram

Air Temperature Monitoring

In production workshops such as food processing, pharmaceutical manufacturing, and electronics manufacturing, as well as chemical plants, hydropower stations, laboratories, pharmaceutical environments, and warehouses, temperature changes directly or indirectly affect production efficiency, product quality, equipment reliability, and employee health and safety. Therefore, a temperature monitoring system is needed to monitor the temperature in the production environment in real time.

Temperature sensors monitor temperature transmitters in real time, outputting continuous or switching signals. The temperature transmitter consists of a temperature sensor, a transmission module, a zero-drift and temperature compensation module, and a 4-20mA module. It can output temperature signals, facilitating various temperature monitoring methods.

Air Flow Monitoring

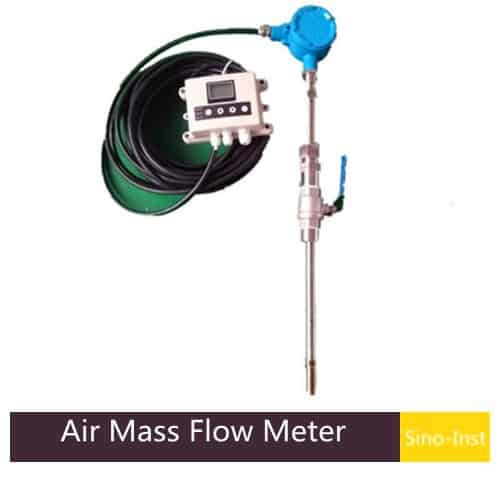

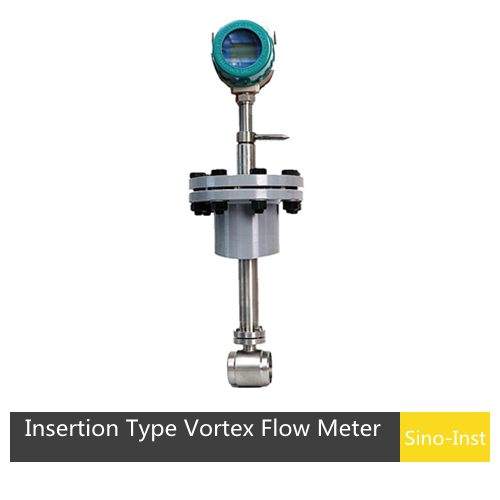

Sino-Inst supplies high-quality industrial air flow meters, including mass flow meters and volumetric flow meters. They can measure pure air, combustion air, and compressed air.

There are various types of flow meters that can be used to measure air, the most important being metal rotor flow meters, throttling differential pressure flow meters, vortex flow meters, and thermal mass flow meters. We support customization for parameters such as high temperature and high pressure.

Sino-Inst also supplies flow controllers for small airflow.

Read more about:

Cases Share

High-Temperature Media Pressure Measurement Case: 900-1200°C

Variable Area Flow Meter Case: Oxygen Flow Measurement

Customized Case: High Temperature and High Pressure Pressure Measurement -100MPa-700℃

Monitoring air temperature, pressure, and flow parameters is crucial in industrial applications. With years of experience, Sino-Inst provides customized solutions for users across various industries.

If you haven’t found the right product yet, please feel free to contact us for customization.

-1.jpg)