Like all switches, flow switches are devices used to connect and disconnect current in a circuit. In industrial systems, flow switches are critical equipment for ensuring production continuity and safety. They are essential for flow monitoring, automated control, and safety protection.

Flow switches are used to control and monitor the flow rate of air, steam, or liquids. Flow switches control the on/off flow of process media by triggering the action of different machines in the system. This helps maintain safe and manageable flow. Flow switches can handle a variety of different media, but the most common are water and air. They are also suitable for oils, gases, and corrosive liquids.

What Is a Flow Switch?

A flow switch is a device used to measure and control the flow rate of liquids, air, or other gaseous media in pipelines, systems, or circuits.

Flow switches can be installed online or as plug-in devices. They must be installed in any equipment that requires gas or liquid flow to operate. Flow switches ensure that the gas or water flowing to the equipment remains within the set parameter range. If the flow rate exceeds these parameter ranges, the switch can open or close to resolve the problem.

What Does a Flow Switch Do?

As mentioned earlier, flow switches are mainly used to monitor and control the fluid flow in industrial process systems. And when the flow level is reached, they perform two functions: closing their contacts and turning on specific equipment, or opening their contacts and turning off specific equipment.

Industrial field

In the industrial field, flow switches are used to monitor the flow of liquids, gases or steam in pipelines. For instance, in the petrochemical and power industries, they can control the flow of raw materials or ensure the safe operation of equipment.

Boiler Application

In boilers, the function of the flow switch is to prevent the boiler from igniting before the fan expels any gas through the flue. It only allows the boiler to ignite when it detects that the fan is rotating at the required speed to expel excess gas. The boiler flow switch can also prevent the boiler from operating under conditions of low water flow or no water flow.

Water treatment

In the field of water treatment, flow switches can monitor the water flow status to prevent equipment from being damaged due to lack of water or overload. In HVAC systems, flow switches control the cooling water flow of chiller units to ensure the safe operation of the equipment.

Thermal conductivity flow switches have no moving parts and are easy to install. They are particularly suitable for these scenarios.

Application of Fire Protection System

In the fire protection system, flow switches are used to detect the flow of fire-fighting water. When the flow reaches the set value, it triggers an alarm signal or directly interlocks to start the fire pump. The flow switch detects the change in the water flow velocity in the pipeline and transmits the action signal to the fire pump control cabinet.

The flow switch detects changes in the water flow velocity within the pipes and transmits the activation signal to the fire pump control cabinet.

The Difference Between Flow Switches and Flow Meters

Compared to flow meters, flow switches have a relatively simple function: controlling the flow rate on and off.

Flow switches are used to control the flow rate of air, steam, or liquids. Flow meters, on the other hand, are used to measure the volumetric or mass flow rate of liquids or gases in a fluid system.

| Feature | Flow Switch | Flow Meter |

| Function | A flow switch detects whether the flow rate has reached a preset threshold. | A flow meter measures the instantaneous or cumulative flow rate of a fluid. |

| Working Principle | A flow switch detects the fluid flow state mechanically or electronically. | A flow meter directly measures the flow rate based on various physical principles. |

| Accuracy | Flow switches have lower accuracy (±5%~±10%). | Flow switches have lower accuracy (±5%~±10%). |

| Range Ratio | Flow switches have a narrow range ratio, typically 1:5~1:10. | Flow meters have a wide range ratio, typically 1:20~1:50. |

| Response Time | Flow meters have a slower response (seconds). | Flow switches have a faster response (milliseconds). |

| Output Signal | Flow switches output binary switching signals. | Flow meters output analog or digital signals (e.g., 4-20mA, pulse). |

| Cost | Low | High |

How Does a Flow Switch Work?

There are different types of flow switches on the market, and their working principles vary. However, they all have one thing in common: when the flow rate reaches the switch’s set value, it will open or close the circuit and trigger the corresponding action.

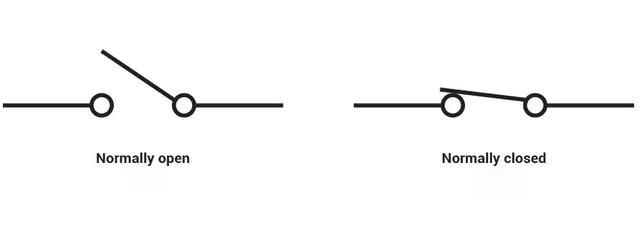

Flow switches are divided into two types: normally open (NO) and normally closed (NC). This is the switch’s default state. If no switch is open, the circuit will be closed until triggered by another means. When using a normally closed switch, the circuit is in the closed (ON) state until triggered.

Types of Flow Switches

Flow switches are classified according to their working principle into target type (baffle type), thermal conductivity type, turbine type, diaphragm type, and Karman vortex street type, etc. The following are the most commonly used flow switches:

Baffle-type Flow Switch

A baffle-type flow switch is also known as a mechanical flow switch. It consists of hinged or spring-loaded blades that directly contact the fluid in the pipe. When the fluid flows at a set value, the blades remain in the initial position. An increase or decrease in flow rate causes the blades to move away from the set value, triggering a small switch to initiate a specified action.

As the fluid flows through the pipe, it impacts a vertically mounted baffle (target plate), causing it to deflect. The deflection angle of the baffle is proportional to the fluid velocity. The higher the velocity, the larger the deflection angle.

Baffle-type flow switches are simple in structure, relatively inexpensive. They have strong anti-interference capabilities, and are suitable for media containing particles. However, their mechanical parts are prone to wear, and poor water quality may affect their stability.

Thermal Flow Switches

Thermal flow switches detect flow by measuring the heat exchange of the fluid medium. Suitable for clean gases or liquids.

The advantage of a thermal diffusion flow switch is that it has no mechanical parts that are prone to wear. The result is less maintenance and a longer service life. Among them, common thermal flow switches include thermistor type, thermocouple type and thermistor type.

Thermal flow switch probe usually contains two key modules: heating module and heat-sensing module. When working, the heating module will continue to emit heat. When there is no medium flowing in the pipe, the heat received by the thermal module remains stable.

When the fluid flows through the pipe, the fluid will take away some of the heat from the heating module. This causes the thermal module to receive less heat. The temperature difference between the two modules changes. By detecting changes in temperature difference and converting them into electrical signals, the flow status of the fluid can be judged and the corresponding switching action can be triggered.

Turbine Flow Switches

Turbine flow switches detect flow velocity by rotating rotor blades. When fluid flows through a pipe, the fluid’s momentum impacts the turbine blades, causing the turbine to rotate. The turbine’s rotational speed is approximately proportional to the fluid’s volumetric flow rate.

Turbine blades are typically made of magnetically conductive materials. Turbine flow switches are characterized by high measurement accuracy and rapid response. However, they require relatively clean fluid to prevent impurities from causing wear on the turbine and bearings.

Electromagnetic Flow Switch

An electromagnetic flow switch uses the electromagnetic principle in a sensor to detect fluid flow rate. An excitation coil is installed on the outside of the flow switch’s measuring tube. When energized, it generates a uniform magnetic field perpendicular to the fluid flow direction.

Electromagnetic flow switches offer high sensitivity and accuracy. They have no flow obstructions within their measuring tubes, resulting in minimal fluid pressure loss. However, electromagnetic flow switches are only suitable for conductive liquids (such as water, acid, and alkali solutions) and not for gases, steam, or pure water.

Piston Flow Switch

A piston flow switch (also known as a water flow switch) uses the pressure difference generated when fluid flows through a piston to complete the switching action. A piston flow switch has a free-floating magnetic piston that responds to the flow rate in the pipe. When the flow rate increases or decreases, the piston movement triggers a sealing switch, initiating the specified action.

Piston flow switches require no power supply and have a simple structure. However, they are sensitive to impurities, and their accuracy is typically ±5%.

The Advantages of Flow Switches

High Reliability

Flow switches are manufactured using special materials and processes. They possess excellent anti-interference capabilities and stability, enabling long-term reliable operation in harsh environments.

For example, mechanical flow switches (such as baffle type) have a simple structure and small operating contact surface. They are highly suitable for low-flow-rate fluids and fluids containing impurities.

High-Precision Measurement

Flow switches are equipped with high-precision sensing elements. Electronic flow switches support digital keypad or knob settings. Measurement accuracy can reach ±0.5%, providing reliable data support for production processes.

Strong Adaptability

Flow switches can adapt to various media such as water, oil, and gas. They can even detect industrial raw materials with special chemical properties. For example, thermal flow switches operate on the principle of heat exchange, have no requirements on the conductivity of the medium, and are suitable for corrosive fluids.

Automated Control

Flow switches can be linked with PLC, DCS, and other systems to achieve remote monitoring and intelligent management. Electronic flow switches also support 4-20mA analog output and communication protocols, facilitating integration into complex control systems.

Convenient Installation and Maintenance

Some flow switch models support online installation and plug-in installation. Special debris can be cleared online when it becomes blocked, resulting in low maintenance costs.

How Do I Install and Maintain a Flow Switch?

How to install a flow switch?

Choose a suitable installation location.

The flow switch should be installed on the pipeline between the pump outlet and the equipment outlet. The installation location of the flow switch should be a straight pipe section at least 5 times the pipe diameter away from these components.

Installation direction and method

Horizontal installation is suitable for full-pipe media. However, ensure there are no air bubbles in the pipeline and that the probe is in full contact with the fluid.

Vertical installation:

The flow switch should be installed on a pipe section where the medium flows from bottom to top. Inverted installation (pipes with downward flow) is prohibited.

Side-mounted installation is suitable for full-pipe or non-full-pipe scenarios and has strong versatility.

Prepare the pipeline

Ensure the pipeline is clean and smooth. If cutting is necessary, cut precisely to avoid leaks.

Flow guide plate installation

When tightening the flow switch, the flow guide plate should be perpendicular to the fluid flow direction, and the arrow on the flow switch housing should be aligned with the fluid flow direction in the pipeline. The flow guide plate must not come into contact with the pipeline or other devices.

Connect the wiring

Connect the switch to the control system according to the wiring diagram. Ensure the connection is secure and moisture-proof.

Anti-impact measures

If there is a fast-closing valve downstream, a throttle valve should be installed to prevent water hammer from damaging the switch.

How to maintain a flow switch?

- Always disconnect the power and drain the medium from the pipeline before maintenance.

- Check the flow switch fins for scale or corrosion. Clean any dirt promptly.

- For fluids prone to scaling (such as cooling water), regularly remove the sensor for purging or cleaning.

- When reassembling the flow switch, ensure the gaskets are properly installed.

- Simulate flow interruption and flow conditions. Verify the flow switch contacts operate correctly. Check if the linked equipment responds correctly.

- Perform zero-point checks and adjustments regularly. Especially for low flow rate measurements, calibration is necessary to eliminate zero-point drift errors.

How Do I Choose a Flow Switch?

Here are the key factors to consider when selecting a flow switch:

- Minimum and maximum flow rates.

- Pipe diameter, straight pipe length, and installation method.

- Media characteristics. Liquid, gas, or multiphase fluid. Corrosive media require corrosion-resistant materials (such as 316L stainless steel or PTFE coating).

- Accuracy requirements. If your application requires high-precision measurement, prioritize electronic or imported high-end flow meters.

- Environmental requirements. High-temperature or vibration-prone environments require high-temperature resistant and vibration-resistant designs. Explosion-proof instruments should be selected for flammable gas environments.

- Equipment purchase budget, installation and commissioning costs, and subsequent maintenance costs.

If the above information is not helpful, you can consult our professional engineers; selecting a flow switch will become quick and easy.

More Flow Measurement Solutions

Flow switches are essential tools for improving efficiency and safety across various industries. Industrial flow switches are manufactured using special materials and processes, exhibiting superior anti-interference capabilities and stability.

Flow switches can adapt to various types of fluid media, including water, oil, and gas. They offer numerous advantages to meet the needs of different industrial scenarios. Such as improved efficiency, cost savings, enhanced safety, high adaptability, and ease of installation and maintenance.

Sino-inst manufactures and supplies a wide range of flow switches. We can customize instrument specifications according to users’ specific needs and field operating conditions. If you need to purchase flow switches or have any technical questions, please feel free to contact us. We will reply to your inquiry as soon as possible.

-1.jpg)