Gravity flow meters can be used to measure flow in gravity-fed pipelines. These pipelines typically do not have a pressurized pump. Instead, the fluid flows downward from a height, relying on gravity. This type of measurement is often difficult due to the slow flow rate and low flow rate.

In our experience, if the fluid is fully filled in the pipeline and the flow height is at least 1 meter, a gear flow meter can be used to measure flow. This type of flow meter is commonly used in diesel and fuel supply systems.

Working Principle of Gear Gravity Flow Meters

Gear flow meters are high-precision flow meters that measure volumetric flow. They operate based on the positive displacement principle. The flow of the medium causes the gears to rotate, and the gear rotation is detected by two non-contact pulse detectors. Each tooth generates a pulse, ultimately producing a frequency signal proportional to the flow rate. This in turn provides the flow rate value, Q.

Gear flow meters feature high machining precision, precise installation, and high resolution. Gear flow meters require lubricating media and cannot measure non-lubricating media. Gear flow meters are also unsuitable for fluids containing solid particles. Gas entrained in the measured liquid medium can also cause measurement errors.

Advantages of Gear Gravity Flow Meters

- Low installation requirements.

First, gear flowmeters do not require straight pipe sections for installation and can be installed directly in bends or even flexible pipes.

2. High Precision and Repeatability

Achieve highly accurate measurements within a narrow range, with an accuracy level of ±0.5%. Whether measuring large or small flows, the gear flowmeter maintains a repeatability of ±0.1% when measuring the same flow rate multiple times. This eliminates measurement errors and provides high repeatability, providing users with reliable flow data.

- Strong Acid and Alkali Resistant

When handling fluids containing corrosive substances, it maintains long-term stable performance and is not easily corroded by the media, significantly extending the flowmeter’s service life and reducing measurement errors caused by contamination. This robust corrosion and contamination resistance makes the HGF100 series gear flowmeter widely used in industries such as the chemical, petroleum, and pharmaceutical industries that handle corrosive or contaminating media.

- High-Pressure Resistant, Capable of Measuring Gravity and Negative Pressure Conditions

Maintains stable measurement capabilities in a variety of extreme operating environments. This flowmeter operates under pressures up to 45 MPa, unaffected by pressure fluctuations. It can measure free-flow flow up to 1 meter and even negative pressure flow.

- High and Low Temperature Resistance

It is highly resistant to high and low temperatures, operating within a wide temperature range from -196°C to 200°C. It provides accurate and reliable flow data, helping users achieve process control and production optimization.

- Wide Measurement Range

It can measure flow rates as low as 0.3 L/H, accurately measuring both large and small flows.

- Wide Turndown Ratio

With a turndown ratio of 1:150 and a low starting flow rate, this flowmeter is adaptable to various applications with large flow rate fluctuations, eliminating the need for frequent device replacement or parameter adjustments, improving measurement convenience and efficiency.

- Multiple Output Signals

The oval gear flowmeter can be configured as a mechanical flowmeter without a signal output. Alternatively, it can be equipped with an electronic meter, similar to the GF gear flowmeter. It offers a variety of output options: pulse output, analog 4-20 mA, RS485, and HART. Special signals such as 0-5V, 0-10v, 1-5V, 2-10V, etc. can also be customized.

Featured Gravity Flow Meters

The gear flowmeters supplied by Sino-Inst are mainly GF gear flowmeters and oval gear flowmeters.

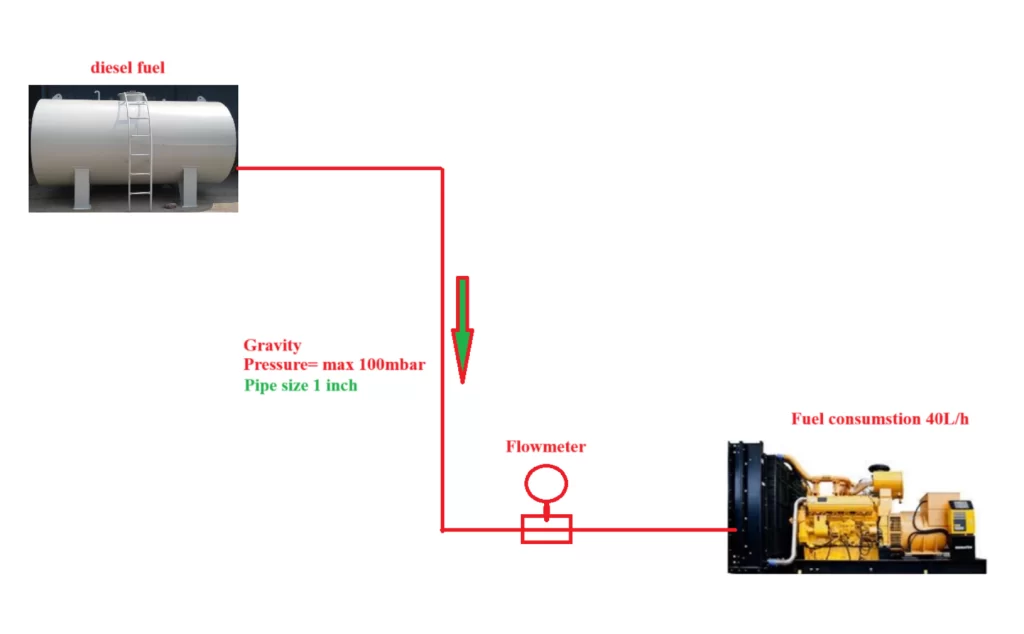

Gravity Flow Meters for Diesel/Fuel Feed

Our client contacted us. They needed to measure the diesel flow rate from an elevated diesel storage tank. The diesel would flow from the elevated tank to a diesel generator. The generator’s diesel consumption was estimated to be 40 L/h. There were no booster pumps or other equipment in the pipeline. The flow was driven solely by gravity, with a maximum pressure of 100 mbar due to the height difference.

We therefore recommended the GF Series Gear Flowmeter, Model GF06.

- Gear Flowmeter

- GF06

- Measuring Range: 10-500 L/h

- G 1/2 Thread Mounting

- -20-80°C

- Pressure Resistance: 1.6 MPa

- 24VDC Power Supply

- On-Site Digital Display

- 4-20mA Signal Output

- 0.5% FS Accuracy

- Cast aluminum, 304 stainless steel available.

Gravity Flow Meters Applications

Gravity flow meters are suitable for most clean liquids, including those without any solid particles or contaminants. They are particularly advantageous for measuring high-viscosity liquids and oils.

- Commonly measured media include:

- Polyvinyl alcohol, resins, adhesives;

- Heat transfer oil, hydraulic oil, lubricating oil, grease;

- Diesel, gasoline, kerosene, fuel oil;

- Ink, asphalt;

- Liquid nitrogen, coolant, solvents;

- Edible oil, fish oil, and food packaging;

- Heavy oil, crude oil, light oil, asphalt;

- Syrup, water, and other clean liquids.

Gear Gravity Flow Meters are widely used in the following industries:

Crude Oil Transportation and Metering: Gear flowmeters can adapt to the viscosity of crude oil, providing stable and accurate flow data, helping oil companies effectively manage production and sales.

Chemical Raw Material and Product Metering: In chemical production, controlling the flow rate of raw materials and products is crucial for ensuring product quality and process stability. For example, in the production of synthetic rubber and plastic granules, gear flowmeters can accurately measure the flow rate of various liquid chemical raw materials, enabling precise control of the production process.

Beverage Filling: In beverage production lines, accurate filling volume control directly affects product quality and packaging efficiency. Gear flowmeters can be installed on filling machines to monitor and control the liquid flow in real time, ensuring that each bottle of beverage meets the standard volume requirements, reducing waste and improving production efficiency.

Edible Oil Production and Packaging: The quality and packaging specifications of edible oil are important to consumers. Gear flowmeters can be used in the production process of edible oil, including raw material transportation, blending, and finished product packaging, ensuring the accurate net content of each container or bottle of oil.

Pharmaceutical Formulation Production: In pharmaceutical production, gear flowmeters meet the high accuracy and reliability requirements of the pharmaceutical industry for flow measurement. They are used to accurately measure the flow rate of liquid and powder materials, ensuring the consistency and stability of pharmaceutical production.

Automotive Coating: In automotive coating processes, gear flowmeters accurately measure the flow rate of paint, ensuring uniform and consistent coating, achieving high-quality automotive finishes.

Pure Water Preparation: In water treatment systems, gear flowmeters can be used to monitor and control the flow rate of water in processes such as reverse osmosis and ultrafiltration, ensuring the stability and reliability of the pure water preparation process.

How to Calculate Gravitational Flow Velocity?

Gravitational flow velocity refers to the speed of a fluid flowing under the influence of gravity. Calculating this velocity is crucial for fluid dynamics research and engineering applications.

Gravitational flow velocity, also known as the velocity due to gravitational head, is the speed at which a fluid flows in a certain direction under the influence of gravity. It commonly occurs in scenarios such as pipelines, rivers, and open channels.

The calculation formula is: Flow velocity (v) = (2g * h)^0.5. Where g is the acceleration due to gravity, and h is the hydraulic head (vertical distance) of the fluid.

Methods for Calculating Gravitational Flow Velocity:

- Determine Fluid Parameters: First, determine the properties of the fluid, including density and viscosity, as these parameters affect the flow characteristics.

- Measure Hydraulic Head: Measure the vertical distance from the fluid’s location to the reference level to obtain the hydraulic head (h).

- Apply the Formula: Substitute the acceleration due to gravity (g, typically 9.81 m/s²) and the hydraulic head (h) into the formula and calculate the square root to obtain the flow velocity (v).

- Correction Factors: In practical applications, due to factors such as fluid friction and pipe roughness, correction factors need to be introduced to adjust the calculated result.

More Flow Measurement Solutions

Gear flowmeters are adaptable to fluids of varying viscosities and corrosiveness, and are easy to install and maintain, providing a reliable flow measurement solution for industrial production.

Gear flowmeters are an excellent choice for specialized gravity flow applications. If you require flow measurement, please feel free to contact our Sino-Inst sales engineers!

-1.jpg)