Propane is a common fuel source used in a variety of industries, including manufacturing, agriculture, and transportation. Propane flow meters come in various types and designs, tailored to the specific nature of propane, whether it’s in gaseous or liquid form.

Given that propane can exist in both states—depending on temperature and pressure—understanding how to measure the flow of each is critical.

Why Choose Propane?

LPG gas (liquefied petroleum gas) is a hydrocarbon with propane and butane as the main components, which is obtained as a by-product during the extraction and refining of oil and natural gas. Liquefied petroleum gas is so important that flow meters used to measure liquefied petroleum are also purchased in large quantities.

Composition of LPG gas Main components: propane (C3H8), butane (C4H10);

Others: methane, ethane, propylene, butane;

Propane is:

- Versatile

- Cost-Effective

- Environmentally Friendly

- Readily Available

- Safe

Gas Propane Vs Liquid Propane

| Propane Gas | Liquid Propane |

| In its gaseous form, propane is commonly used for residential heating, cooking, and powering small appliances. Propane gas is also prevalent in industrial applications. Industrially, propane can be separated from oilfield gas and cracking gas. It can be used as a raw material for the production of ethylene and propylene or as a solvent in the oil refining industry. A mixture of propane, butane and a small amount of ethane can be used as a civilian fuel after liquefaction, namely liquefied petroleum gas. | When stored under pressure, propane becomes a liquid. This liquid form is mainly used in industrial settings. Liquid propane is also stored in tanks, making it more compact and easier to transport compared to its gaseous form. Since the main component of liquefied propane is propane, its combustion temperature and calorific value are relatively more stable, which can provide a more reliable combustion effect. Liquid propane is more widely used in industrial fields, such as automobile fuel, torch combustion, etc. |

Propane Gas Flow Meters

Propane gas flow meters are specifically designed to measure the flow of gaseous propane. These meters are often used in residential and small commercial applications where propane is used for heating or cooking. However, they are also vital in industrial processes. Propane is part of the manufacturing or energy production workflow.

There are several types of propane gas flow meters, each with a unique operating principle:

Vortex flow meters are suitable for measuring steam as well as a variety of liquids and gases. As fluid moves across a vortex meter shedder bar, vortices form. The frequency of the vortices shedding is proportional to the fluid velocity.

Even for the steam flow rate, Vortex flow meters are the perfect choice. Pressure and Temperature compensation ensure measurement accuracy. When we use them to measure steam or gas flow in pipes with variable operating pressure and temperature.

Gas Turbine Flow Meter, is the flange type turbine flow meter. Turbine flow meter is the most popular equipment to measure flow electronically. They offer a wide flow and application rangeability.

SI-3201 GAS Turbine Flow Meter, is perfect choice for natural gas flow rate measurement. Turbine flow meters are suitable for gas and liquid measurement. They offer a wide flow and application rangeability. Turbine Flow Meters are easy to installation, maintain, durable and versatile.

Thermal gas mass flowmeter is an instrument that uses the principle of heat conduction to measure fluid flow. The instrument uses the constant temperature difference method to accurately measure the gas mass flow.

As the flow rate of the medium increases, the heat carried away by the medium increases. According to the proportional relationship between the temperature difference and the flow rate of the medium, the flow rate Q of the fluid can be obtained.

Most thermal flowmeters are used to measure gas, and only a small number of thermal flowmeters are used to measure small liquid flows.

Differential Pressure Flow Meters, also called DP flow meters. Differential pressure flow meters consist of flow sensors and pressure/differential transmitters. Flow sensors are the important part of differential pressure flow meters. Like: Orifice plate, Venturi tube, Wedge, V-cone and Averaging Pitot Tubes.

Liquid Propane Flow Meters

Unlike gas flow meters, liquid propane flow meters need to account for the higher density and viscosity of liquid propane, making their design and operation quite different from those used for gaseous propane.

Common types of liquid propane flow meters include:

- Positive Displacement Flow Meters: Positive displacement flow meters act like a hydraulic pump in reverse. The moving parts inside the flow body are designed so that a finite amount of liquid is allowed to fill a chamber and then is expelled, before it is then filled again with the same amount.

- Coriolis Flow Meters: Just like in gas flow applications, Coriolis meters can also measure the flow of liquid propane. Coriolis mass flow meters measure mass through inertia.

- Turbine Flow Meters: Turbine meters for liquid propane work on the same principle as those for gas.

- Vortex flowmeter: Vortex flowmeter can not only measure the flow of steam and gas, but also measure the flow of liquid.

Fundamental Applications of Propane Flow Meters

Some of the key areas where propane flow meters are most commonly used:

- Residential Usage

- Commercialized and Industrial Settings

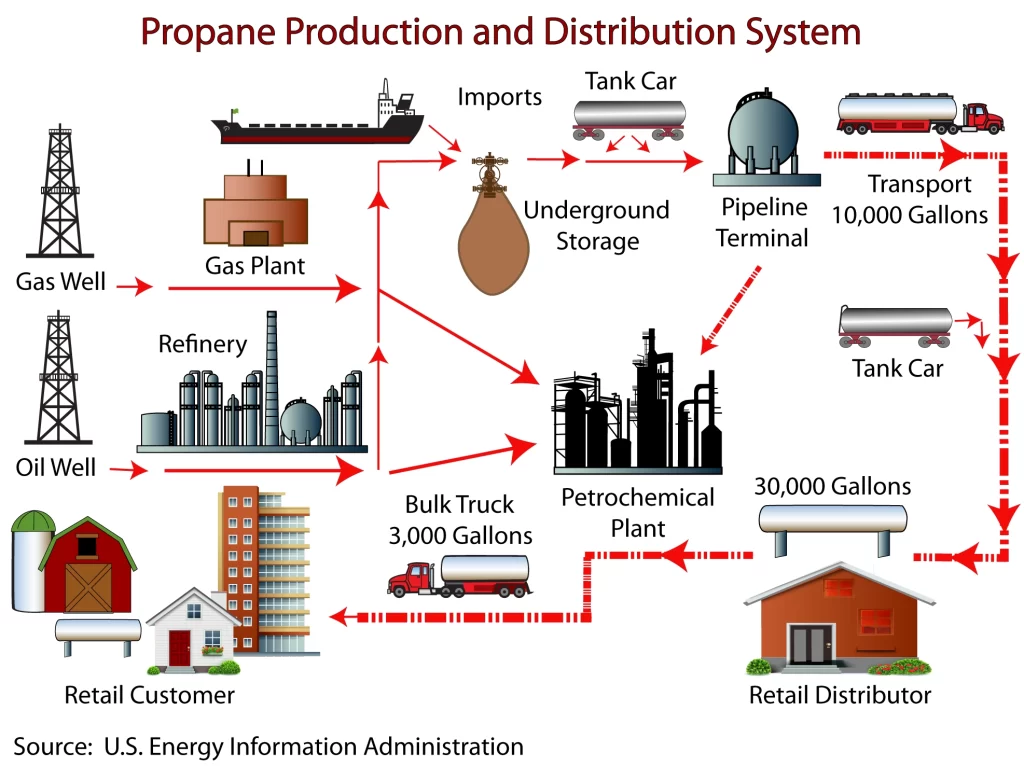

- Bulk Propane Distribution

- Transportation and Fueling Systems

Tips for Buying Propane Flow Meters

To ensure a successful LPG flow meter purchase, consider the following tips:

- Propane status

- Flow rate

- Measurement environment: temperature and pressure bars

- Accuracy requirements

- Installation conditions

- Research different flow meter types and their benefits and limitations.

- Compare specifications, features, and prices from multiple vendors.

- Consider long-term costs, including maintenance, calibration, and potential downtime.

More Flow Measurement Solutions

- Techniques, Importance, and Challenges of Natural Gas Flow Measurement

- DP Transmitter for Flow Measurement

- Guide To Vortex Flow Meters For Steam Applications: Steam Vortex Flow Meter In detail

- Featured Gas Turbine Flow Meter for Natural Gas and Other Gases

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

By choosing the right flow meter for your specific needs and ensuring proper maintenance and calibration, you can maximize energy efficiency, reduce costs, and ensure safety in propane handling.

The use of ‘propane flow meters’, whether for ‘propane gas’ or ‘liquid propane’, is nitpicking to guarantee efficient and safe usage across multiple sectors. If you have any technical questions, please feel free to contact our engineers!

-1.jpg)