What Is a Differential Pressure Flow Meter?

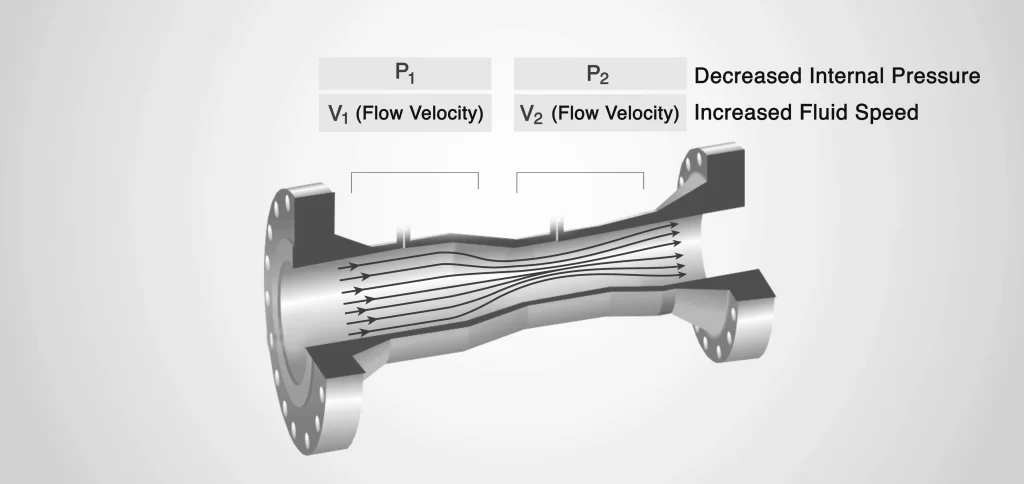

A differential pressure flow meter is a device that measures flow rate by measuring the pressure difference. The differential pressure transmitter is the key component in differential pressure flow measurement. Using a differential pressure transmitter, the pressure difference before and after a pipe throttling device can be measured. Then, based on the measured value, the flow rate is calculated using Bernoulli’s equation.

The measuring elements of a differential pressure transmitter are carefully divided into multiple levels, resulting in extremely small measurement errors, thus enabling accurate flow measurement.

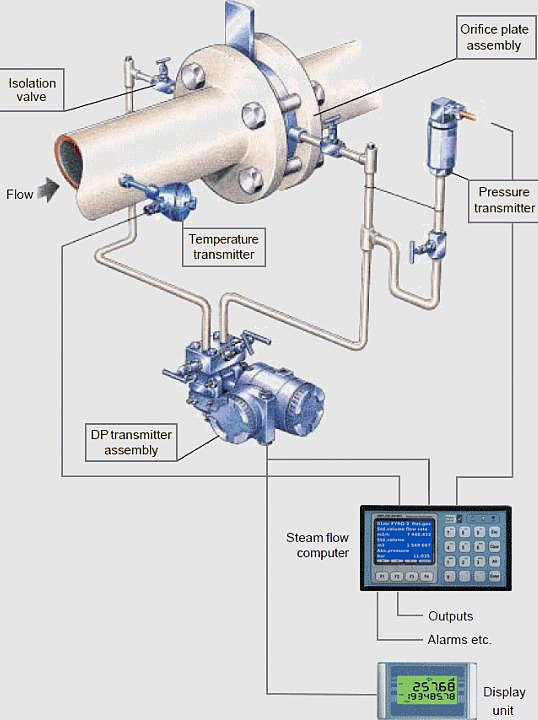

Differential Pressure Flow Measurement System

Sometimes, people are accustomed to dividing the structure of a differential pressure flow meter into primary elements, secondary elements, and sometimes even tertiary elements. Here, we briefly explain that the differential pressure flow measurement system is mainly composed of the following parts:

- Throttling element: such as the throttling orifice plate, Annubar, etc.

- Differential pressure transmitter: detects the differential pressure value before and after the throttling element.

- Flow Totalizer: calculates the flow value based on the differential pressure. Temperature and pressure compensation can also be performed.

- Accessories: pressure pipes, valves, connectors, etc.

Advantages of DP Flow Measurement Systems

High Accuracy: Differential pressure flow meters measure flow rate by measuring the pressure difference generated as fluid flows through a pipe. They offer high accuracy, meeting precise flow measurement requirements.

Wide Applicability: Differential pressure flow meters are suitable for fluids of various viscosities, including single-phase, multiphase, clean, dirty, and viscous flows. They are also suitable for different operating conditions (e.g., normal pressure, high pressure, vacuum, normal temperature, high temperature, low temperature) and pipe diameter ranges (from millimeters to meters). Their wide range of applications is unmatched by any other type of flow meter.

Good Stability: Differential pressure flow meters have a simple structure and stable, reliable operation. They are highly adaptable to changes in fluid pressure, temperature, and other parameters, maintaining stable measurement performance over long periods.

Easy Installation: Differential pressure flow meters are relatively easy to install. They typically use flange or threaded connections, facilitating installation and maintenance.

High Reliability: Differential pressure flow meters have no moving parts. They are not easily damaged or worn, resulting in a long service life. Furthermore, it is unaffected by suspended solids, particulate matter, or other impurities within the pipeline.

Lower Cost: Compared to other flow meters, differential pressure flow meters have lower manufacturing costs. Their price is relatively suitable for large-scale applications.

Multiple Models Available: Differential pressure flow meters are available in a variety of models, including orifice plate, nozzle, venturi, and annubar types. Suitable for different flow ranges and fluid types, the appropriate model can be selected based on specific requirements.

Featured DP Transmitter for Flow Measurement

Sino-Inst produces and supplies a full range of differential pressure transmitters. Including compact type, intelligent type, high static pressure type, high accuracy type, etc.

Benefits

- Differential pressure transmitters are available in a variety of ranges for a wide range of applications;

- Even at high static pressures, differential pressure transmitters can measure small differential pressures of only a few millibars.

- An economical alternative to flow transmitters;

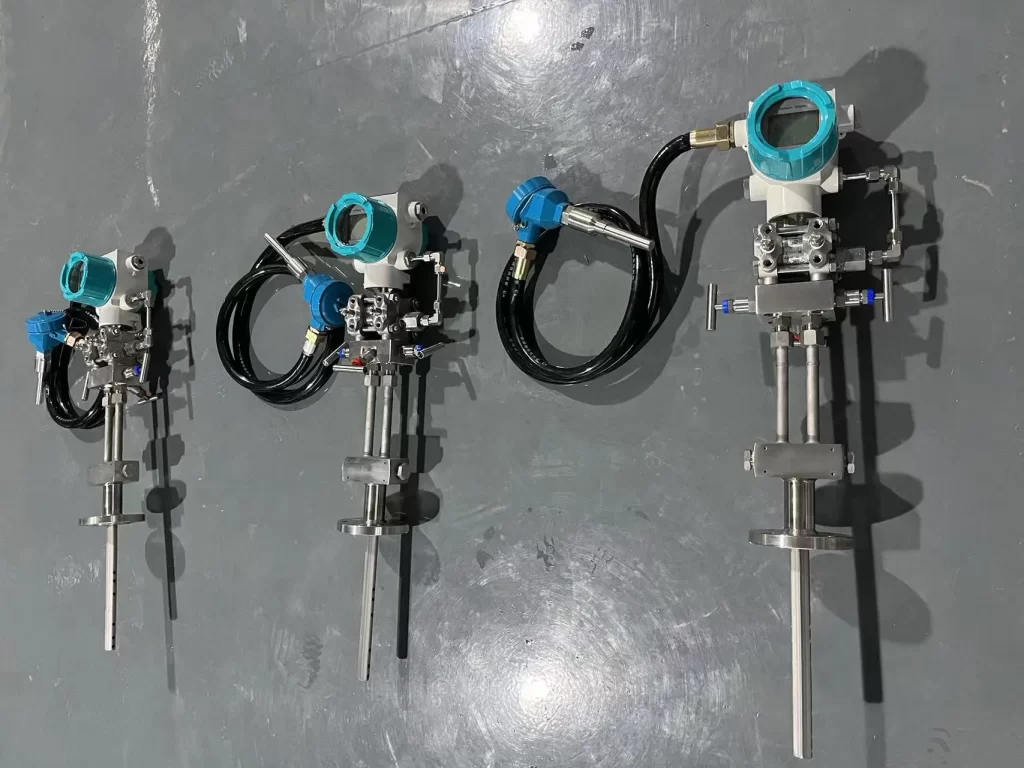

Featured Types of Primary Elements

Primary elements are devices that convert the flow rate of a measured fluid into a differential pressure signal; they are also called throttling devices. They include the throttling element and the pressure tapping device. Primary elements have a simple structure and can measure the flow rate of single-phase fluids under various operating conditions, including high temperature and high pressure.

However, the selection, design, and production of primary elements require rigorous calculations based on flow parameters.

Read more about: A Practical Guide to 5 Different Types of Flow Elements

Selecting a DP Transmitter for Flow Measurement

Selecting a DP Transmitter requires matching the instrument’s capabilities to the requirements of the application.

Key specifications to consider include:

- Line size: Determines full-size flow and primary component design;

- Fluid type: Liquid, gas, steam compatibility;

- Maximum working pressure: Pressure rating of valve body/flange;

- Temperature limit: Temperature limits of the primary element, sensor, and transmitter;

- Viscosity range: Higher viscosity fluids may require special considerations;

- Required accuracy and turndown ratio;

- Maximum allowable permanent pressure loss;

- Required output: 4-20mA, HART, Modbus;

- Explosion-proof certification: ATEX, IECEx, FM, etc.;

- Other factors include pipeline layout, straight pipe requirements, flow profile, and environmental conditions.

It is recommended to contact our technical engineers for confirmation when selecting a DP Transmitter for Flow Measurement. We will perform a rigorous differential pressure calculation based on your measurement parameters and issue a differential pressure calculation report, similar to the document below.

Technical Support

More Differential Pressure and Flow Measurement Solutions

- Industrial Differential Pressure Sensors | Sino-Inst

- 4-20mA Flow Meters | Flow Meter Signal Output Guide

- Different Diesel Level Sensors for Diesel Tank Level Measurement

- Differential Pressure Transmitters – Guide and Selection

- DP Transmitters for Filter Differential Pressure Monitoring

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

DP Transmitter for Flow Measurement can continuously and accurately generate pressure drop in the pipe. Then use the two pressure measurements to measure the flow in the pipe.

Differential pressure flow transmitters can be easily installed in a variety of applications. The differential pressure transmitters supplied by Sino-Inst support various signal outputs, communication protocols, etc. They can be compatible with the user’s industrial control system.

Sino-Inst is committed to providing users with effective tools for measuring flow. If you need to configure a differential pressure transmitter for flow measurement or have related technical questions, please contact our sales engineer!

-1.jpg)