A Variable Area Flow Meter is a flow meter that can measure the volumetric flow of liquid, gas or steam. It is a type of differential pressure flowmeter. Also called a rotameter.

Within the Variable Area Flow Meter, gas or liquid moves the float until equilibrium is reached. The user can read the gas or liquid flow rate from the scale next to the tube or from the scale on the tube. Variable Area Flow Meter is a cost-effective flow measurement solution for small diameter, low flow gas, liquid, and steam.

variable area flow meter working principle

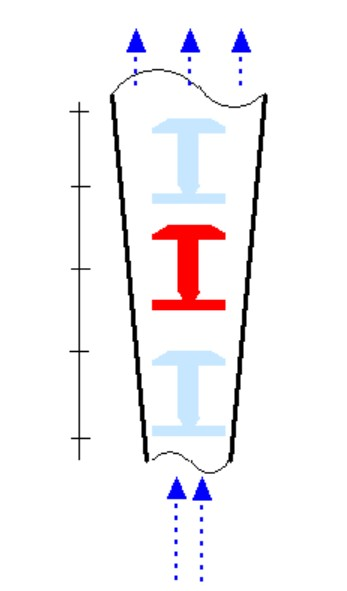

The operation of the variable area flow meter is based on the variable area principle:

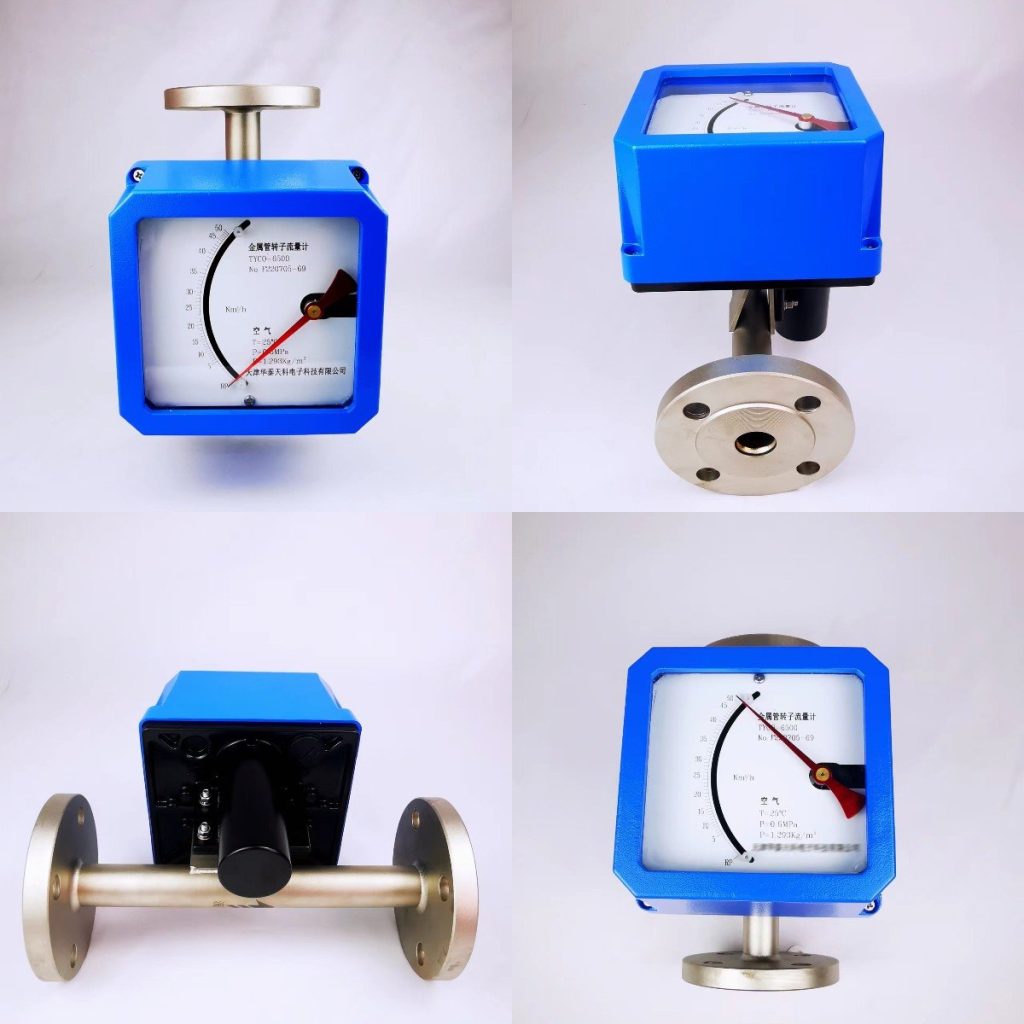

The variable area flow meter consists of two parts. One part of the rotameter is a tapered tube that gradually expands from bottom to top; The other piece of the rotameter is a rotor placed in a tapered tube that can move freely up and down along the center line of the tube.

When measuring the flow rate of a fluid, the fluid to be measured flows in from the lower end of the tapered tube. The flow of the fluid impacts the rotor and produces a force on it (the size of this force changes with the flow rate). When the flow rate is large enough, the The force generated lifts the rotor and raises it. At the same time, the measured fluid flows through the annular section between the rotor and the tapered tube wall and flows out from the upper end.

When the force exerted on the rotor by the measured fluid flows is exactly equal to the weight of the rotor in the fluid (called the displayed weight), the rotor is in a balanced state and stays at a certain height.

Analysis shows that there is a corresponding relationship between the position and height of the rotor in the tapered tube and the flow rate passing through it. Therefore, by observing the position and height of the rotor in the tapered tube, the corresponding flow value can be obtained.

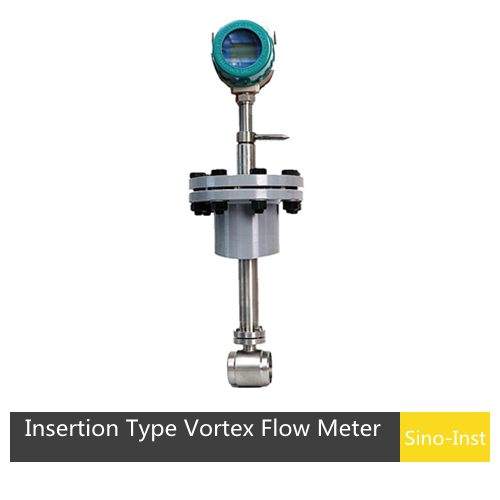

Featured Variable Area Flow Meters

Advantages and disadvantages of variable area flow meter

Advantages:

- High accuracy: The rotameter adopts a mechanical structure and can achieve high measurement accuracy. Suitable for occasions with high flow requirements.

- Good stability: The rotameter has a simple and reliable structure, good stability, and is not easily affected by external interference. Effectively ensure the accuracy of measurement results.

- Wide range of applications: Rotameter can measure the flow of various media such as liquid, gas and steam. It has a wide range of applications and strong versatility.

- Easy to maintain: The main components of the rotameter are the rotor and bearings, and the structure is relatively simple. Easy to maintain and clean, no additional specialized equipment is required.

- Low cost: Rotameters are less expensive to manufacture than some other types of flowmeters.

Disadvantages:

- Large pressure loss: Since there is a circulation channel inside the rotameter, a certain resistance will be generated when the medium passes through, resulting in a certain pressure loss.

- Rigorous fluid requirements: Rotameters are sensitive to the properties of the medium fluid. Factors such as viscosity and temperature have a great influence on the measurement results. The parameters of the medium need to be strictly controlled.

- Limited flow range: The measurement range of the rotameter is relatively narrow. For larger or smaller flow measurements it may not be sufficient.

- Affected by impurities in the medium: If there are impurities such as particles and fibers in the medium, they will adhere to the rotor, resulting in low accuracy. Requires routine cleaning and maintenance.

variable area flow meter types

Common ones may include plastic tube variable area flow meters, glass tube variable area flow meters and metal rotor flow meters. This is distinguished by material. In fact, variable area flow meters can be divided into different categories according to different classification standards. The following content is for your reference.

How is a variable area flow meter different from an orifice meter?

Simply put, the variable area flow meter uses the gravity of the rotor to measure the flow, and the orifice plate uses the pressure difference before and after the fluid to measure the flow.

- Both orifice flowmeters and metal rotor flowmeters can be used to measure steam flow.

- In terms of accuracy, the accuracy of the orifice flowmeter is higher than that of the metal rotor flowmeter.

- Structurally speaking, the orifice flowmeter has no moving parts, while the metal rotor flowmeter has moving parts.

- In terms of lifespan and maintenance, the orifice flowmeter is simple to use and easy to maintain.

Read more about: Orifice Plate Flow Meter.

Order Guide

- First consider the media properties. Chemical resistance to fluids The most common float material is 316 stainless steel, however, for some special applications, Hastelloy, aluminum and PVC can be used.

- What are the minimum flow rate and maximum flow rate of the flow meter?

- What are the minimum and maximum process temperatures?

- What are the pipe sizes?

- Do you want to use a direct-reading rotameter or are you okay with reading the results using a lookup table?

- How much precision is required?

- Is it necessary to use a valve to regulate flow?

- Is there back pressure?

- What is the maximum process pressure?

More Featured Flow Meters

- Flowmeter Selection Guide | Find the Best One for Your Application

- 11 Flow Meter Types and Their Advantages and Disadvantages

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

Variable Area Flow Meter is the most commonly used flow meter in industry and laboratories. It is also called a rotameter. It can be widely used in flow measurement and process control in complex, harsh environments and various media conditions.

Our Sino-Inst mainly supplies metal Variable Area Flow Meters, which can be customized for high temperature, high pressure, corrosive media, etc. measurements. If you need to purchase Variable Area Flow Meter or have related technical questions, please feel free to contact us.

-1.jpg)