The Electromagnetic Heat Energy Meter is a meter that measures the heat released by the heat-carrying fluid in the heat transfer system. Electromagnetic Heat Energy Meter is an inductive meter for measuring conductive media. It is suitable for measuring the volume flow rate of conductive liquids with a conductivity greater than 5us/cm.

The same Electromagnetic Heat Energy Meter can measure heat loss and cooling loss separately. In the heating system, only heat is measured, so it is called a heat meter; in the energy consumption measurement of central air-conditioning water, the loss of heat (winter) and cold (summer) is designed, so it is also called a cold heat meter.

| Nominal diameter: | DN50~DN1400 |

| Medium temperature: | -30℃~180℃ |

| Display: | It has the function of simultaneously displaying accumulated heat, accumulated flow, instantaneous heat, instantaneous flow, inlet water temperature, outlet water temperature, temperature difference and other data, and can query and display parameters such as flow rate and power outage records. |

| Temperature sensor type: | PT1000 |

| Heat unit: | KJ, MJ, GJ, kwh, Mwh optional |

Features of Electromagnetic Heat Energy Meter

- The electromagnetic heat meter uses a 16-bit microcontroller for data calculation and a platinum thermal resistor for temperature measurement. Electromagnetic flowmeters measure flow. It has high measurement accuracy, stable and reliable operation, and excellent performance.

- The measurement accuracy is not affected by changes in parameters such as viscosity, density, pressure, conductivity, and fluid distribution of the heat-carrying fluid.

- There are no resistance parts in the measuring tube, no pressure loss, and it is not affected by poor water quality.

- Wide measuring flow range. The flow rate can be set arbitrarily within the range of 1m/s-10m/s.

- The electromagnetic heat meter has a large-screen LCD display. It can read clearly under strong light and no light conditions.

- It has the function of simultaneously displaying accumulated heat, accumulated flow, instantaneous heat, instantaneous flow, inlet water temperature, outlet water temperature, temperature difference and other data. Parameters such as flow rate and power outage records can be queried and displayed.

- The electromagnetic calorimeter adopts the thermal enthalpy correction method of random temperature changes. Ensure accurate measurement under different water temperatures.

- It has unified DC signal and frequency signal output functions. And this function can switch between heat and flow parameters.

- It has batch processing (quantitative output), equivalent pulse output, and keyed direct clearing functions.

- With digital communication output function. Facilitate remote communication.

- With password protection function. Users without password cannot modify working parameters.

Specifications

| 1. Technical parameters of electromagnetic thermal energy converter: | |

| Power supply: | 220V AC(110VAC ~245VAC)、24VDC |

| Power consumption: | ≤20W (matching power consumption) |

| Accuracy level: | Level 0.5 or Level 1 (matching accuracy) |

| Protection level: | IP65 |

| Ambient temperature: | Category A |

| Temperature resolution: | 0.01℃ |

| Optional temperature measurement range: | -30℃~180℃ |

| Temperature difference measuring range: | 1℃~90℃ |

| Maximum flow reading (m3): | 9999999999 (tens) |

| Maximum heat reading (Mwh): | 9999999999 (tens) |

| Heat unit: | kJ, MJ, GJ, kwh, Mwh optional |

| Analog output: | 4 ~ 20mA DC / 600 load resistance (switchable between heat and flow parameters) |

| Pulse output: | Maximum frequency 5000Hz, pulse width 0.1ms ~ 999.9ms (can switch between heat and flow parameters) |

| communication: | RS-485 (RS-232, M-BUS, HART, etc. optional) |

| 2. Technical parameters of electromagnetic flow sensor: | |

| Nominal diameter: | DN10 ~ DN2200mm |

| Nominal pressure: | 0.6MPa ~4MPa |

| Lining material: | High temperature resistant rubber, PTFE, PFA, F46 |

| Electrode material: | Molybdenum-containing stainless steel, Hastelloy B, Hastelloy C, titanium, platinum/iridium alloy, tantalum |

| Body material: | carbon steel, stainless steel |

| structure type: | Split type, integrated type |

| Medium temperature: | -30℃~180℃ |

| Connection method: | Flange type, thread type, sanitary clamp connection, etc. |

| 3. Technical parameters of temperature sensor | |

| Sensor type: | PT1000 |

| Installation method: | fixed threaded connection, ferrule threaded connection, fixed flange connection, ferrule flange connection |

| Temperature measurement range: | -50°~200°C |

| Wire length: | 0.6m~15m |

Flow Range

| DN | Flow Range | Pressure |

| DN25 | 1~10m3/h | 4.0MPa |

| DN32 | 1.5~15m3/h | |

| DN40 | 2.5~25m3/h | |

| DN50 | 3.5~35m3/h | |

| DN65 | 6~60m3/h | 1.6MPa |

| DN80 | 9~90m3/h | |

| DN100 | 14~140m3/h | |

| DN125 | 21~210m3/h | |

| DN150 | 32~320m3/h | |

| DN200 | 55~550m3/h | |

| DN250 | 90~900m3/h | |

| DN300 | 130~1300m3/h | |

| DN350 | 170~1700m3/h | 1.0MPa |

| DN400 | 250~2500m3/h | |

| DN500 | 350~3500m3/h | |

| DN600 | 500~5000m3/h | |

| DN700 | 700~7000m3/h | |

| DN800 | 900~9000m3/h | |

| DN900 | 1200~12000m3/h | |

| DN1000 | 1500~15000m3/h |

illustrate:

- Flow range: The accuracy is guaranteed to be 0.5% within the flow range. It can be measured beyond the upper and lower limits, but the accuracy is not guaranteed;

- Flow output 4mA corresponds to 0, and 20mA corresponds to the upper limit of the accuracy range of 0.5%.

- The maximum diameter can be DN2600mm. Please consult customer service for the parameters listed in the table above.

Electromagnetic Heat Energy Meter working principle

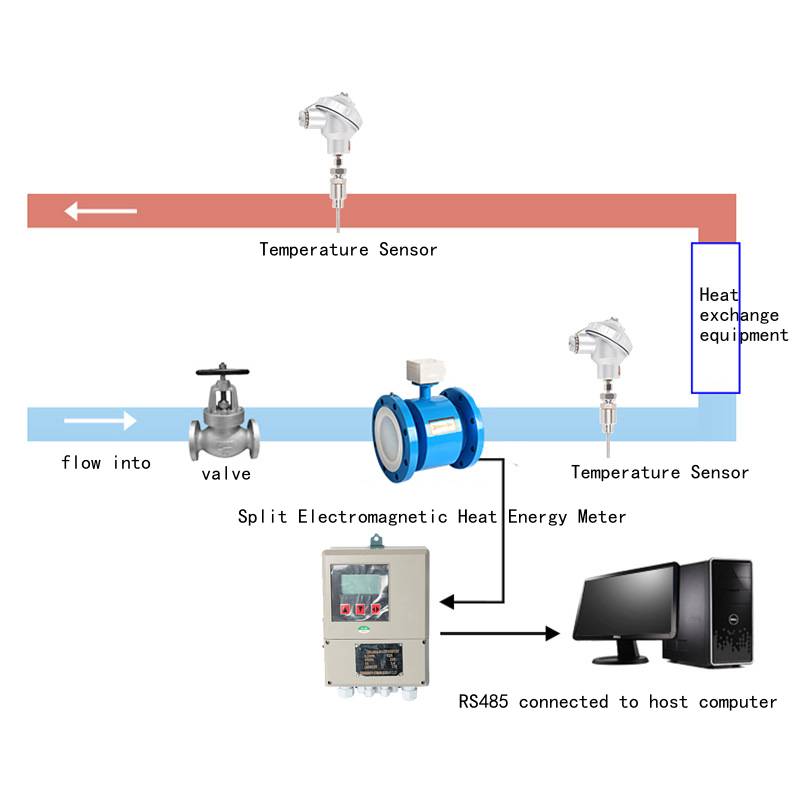

The intelligent electromagnetic energy meter (electromagnetic heat and cooling meter) consists of a flow measurement unit, a heat calculation unit and a paired temperature sensor (PT1000).

The flow meter uses the Faraday electromagnetic induction principle to measure flow, and combined with the supply and return water temperature signals of the paired temperature sensor, it can calculate, accumulate, store and display the cold heat absorbed or released in the heat exchange loop.

The flow meter’s flow and energy calculation unit CPU and sampling module all adopt internationally advanced microcontrollers, which have large memory capacity and high equipment reliability. The heat calculation can truly realize consistent value calculation and achieve high accuracy. The complete set of matched temperature sensors uses platinum resistor Pt1000, and its matching error is ≤0.1℃

Paired temperature sensors (a pair of Pt1000 platinum resistance temperature sensors) are installed on the inlet and outlet pipes of the heat exchange circuit of the air conditioning or heating system to accurately collect the temperature values of the supply and return pipes and transmit signals.

Install the flow sensor (pipeline electromagnetic flowmeter) on the inlet or outlet pipe to accurately collect and calculate the flow value of the pipe network and transmit the signal.

The energy calculator is used to receive temperature and flow signals and calculate and store energy consumption. The effective data in the energy calculator (such as accumulated heat value, cooling capacity value, equivalent flow value, supply and return water temperature and temperature difference) is transmitted to the computer to realize intelligent management.

The computational mathematical model is:

Q=qmΔhdt

In the formula:

Q—heat released: kJ;

qm—the mass of the heat-carrying liquid flowing through the heat energy meter: kg/s;

Δh—the difference in specific enthalpy of the heat-carrying liquid corresponding to the inlet temperature and outlet temperature in the heat exchange loop: kJ/kg;

t—time: s

Read mrore about:

More featured flow and heat meters

Electromagnetic Heat Energy Meter Applications

Electromagnetic heat energy meters, often referred to as electromagnetic flow meters combined with temperature sensors, are instruments designed to measure the energy used or supplied in heating or cooling applications. Here are their primary applications:

District Heating and Cooling Systems: One of the main applications of electromagnetic heat energy meters is in district heating and cooling systems. They help in monitoring and billing the energy consumed by individual units or households.

Industrial Processes: Industries often use heated or cooled fluids in their processes. These meters measure and control the amount of thermal energy being transferred to ensure optimal operation.

Commercial Buildings: In large commercial complexes like shopping malls or office blocks, they can measure the energy consumption of individual tenants or sections of the building.

Residential Buildings: Especially in multi-unit apartments, these meters can be used for individual billing purposes, ensuring that each resident pays only for the energy they consume.

HVAC Systems: Electromagnetic heat energy meters can be integrated into Heating, Ventilation, and Air Conditioning (HVAC) systems to monitor and optimize energy consumption, leading to more efficient system operation.

Data Centers: Due to the significant heat produced by servers, data centers often use liquid cooling systems. These meters can monitor the amount of thermal energy being removed, assisting in maintaining optimal operating temperatures.

Geothermal Energy Systems: These meters are pivotal in geothermal setups where there’s a need to measure the energy extracted from or returned to the ground.

More Flow Measurement Solutions

What Is Solvent Flow Meter? Industrial Selection Guide

Mechanical Flow Meter 101-Mechanical Flowmeters Selection Guide

Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

Volumetric Flow Meters: Comprehensive Guide and Product List

Choosing the Right Inline Water Flow Meter

Portable Ultrasonic Flowmeters | Best Price for Easiest Measurement

Electromagnetic Heat Energy Meter uses a high-precision, high-reliability electromagnetic flowmeter as flow measurement. Use high-precision, high-stability platinum thermal resistors for temperature measurement. This thermal energy meter has very excellent measurement performance.

Electromagnetic Heat Energy Meter can be widely used in the measurement of central heating, heating, air conditioning and other heat in residential areas, office buildings and enterprises and institutions.

We at Sino-Inst have provided heat flow measurement services to users in various industries for many years and have a wealth of experience. Our Heat Energy Meters are widely exported to USA, Saudi Arabia, Singapore, Indonesia and many other countries.

If you need to measure heat, you can contact our Sino-Inst technical engineers for technical support!

Electromagnetic Heat Energy Meter for Heating and Cooling

The Electromagnetic Heat Energy Meter is a meter that measures the heat released by the heat-carrying fluid in the heat transfer system. Electromagnetic Heat Energy Meter is an inductive meter for measuring conductive media. It is suitable for measuring the volume flow rate of conductive liquids with a conductivity greater than 5us/cm.

Product SKU: Electromagnetic Heat Energy Meter for Heating and Cooling

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 550

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)