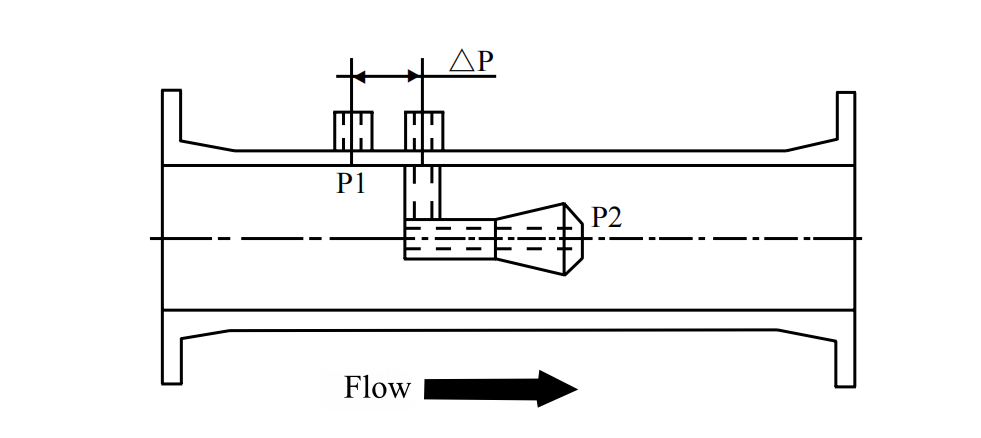

The V-Cone Flow Meter is a flow meter based on the differential pressure principle. Its unique center cone design prevents a sharp contraction of the fluid within the pipeline, resulting in relatively smooth pressure changes. This results in a more stable differential pressure signal, ensuring accurate flow measurement. It is ideal for measuring high-viscosity and dirty media such as liquids, steam, gas, crude oil, and slurries under harsh conditions.

| Diameter | DN15~DN2000 |

| Accuracy | Class 0.5 |

| Temp. range | -200 °C ~ 700 °C |

| Pressure | ≤ 16MPa, 42MPa(maximum) |

| Medium | all kinds of gas, liquid, and steam |

| Normally types | A. Flange type B. Welding type C. Clamped type |

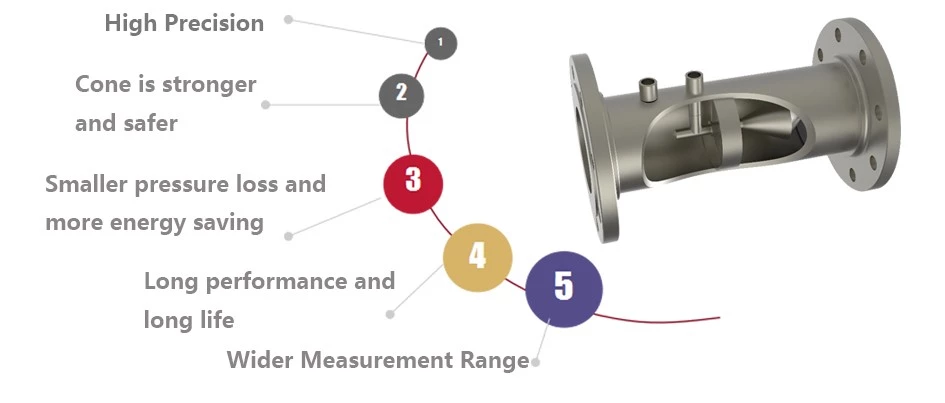

Features

1. Wider flow measurement range.

The unique structure of the V-cone flow sensor and flowmeter enables the generation of sufficiently resolvable differential pressures even at low flow rates. This allows for a lower differential pressure range than traditional differential pressure instruments, extending the range to 10:1.

2. Repeatability is better than ±0.1%; measurement accuracy is better than ±0.5%.

3. Wear-resistant, self-cleaning, with excellent long-term stability and long service life.

4. Short straight pipe requirements

Generally, the upstream flowmeter has a 0-3D diameter and the downstream flowmeter has a 0-1D diameter. If a valve is installed upstream of the V-cone flowmeter, the distance between the flowmeter and the valve should be 3D.

5. Lower pressure drop

Because the outlet edges of the V-cone flow sensor and flowmeter body are not sharp, the fluid pressure changes gradually, minimizing pressure loss caused by vortices generated by friction.

6. Advanced multivariable measurement technology

The two-wire transmitter features multiple sensors operating simultaneously. It can simultaneously monitor and display differential pressure, pressure, temperature, and flow.

7. Comprehensive Compensation Function

The V-Cone flowmeter can dynamically compensate for various factors that affect measurement accuracy online, such as temperature, pressure, Reynolds number, discharge coefficient, expansion coefficient, and compressibility. This improves the flowmeter’s measurement accuracy.

V-Cone Flow Meter Technical Parameters

| Measured media | Liquid, gas (including natural gas), steam |

| Accuracy class: | ±0.5%, ±1.5%, ±2.5% |

| Long-term stability: | ± 0.1% F.S / Y |

| Repeatability: | ± 0.1% |

| Minimum flow velocity: | 0.1m |

| Range Ratio | 10:1 |

| Reynolds number range: | 8 × 10^3 ~ 5 × 10^6 |

| Operating pressure: | 2.5MPa, 4.0 MPa, 6.3 MPa, 10.0 MPa, 16.0 MPa, 26.0 MPa, 42.0 MPa |

| Operating temperature: | -200 °C ~ 700 °C |

| Nominal diameter: | DN15~DN2000 (1/2″~120″) |

| Environment temperature: | ≤ 80 °C |

| Relative humidity: | 5 ~ 85% |

| Output signal: | 4 ~ 20mA |

| Power supply: | 24VDC |

| Voltage of DP transmitter : | 24VDC |

| Communication mode of the DP transmitter: | 4mA ~ 20mA |

| Voltage of intelligent flow totalizer: | 220VDC |

| Current of intelligent flow totalizer: | 4 ~ 20mA |

| Current of the DP transmitter : | 4 ~ 20mA |

| Communication mode of DP transmitter: | RS485/ HART |

| Normally types: | A. Flange type B. Welding type C. Clamped type |

Featured Applications

Compared to traditional flowmeters, V-cone flowmeters offer higher accuracy and stability, especially for complex fluids and unstable flow conditions. Therefore, they have a wider range of applications.

Petrochemical Industry

In the petrochemical industry, V-cone flowmeters are commonly used to monitor the flow of media such as oil, natural gas, and chemical reaction fluids. This industry involves a variety of complex fluids. V-cone flowmeters perform particularly well in special environments with high temperatures, high pressures, and low flow rates.

Metallurgical Industry

During production processes, the metallurgical industry often requires flow monitoring of molten metal or high-temperature gases. V-cone flowmeters operate stably in high-temperature and highly corrosive environments, making them ideal flow measurement tools for the metallurgical industry.

Food and Pharmaceutical Industry

V-cone flowmeters, due to their adaptability to fluid velocity fluctuations, are commonly used for monitoring production processes of liquid pharmaceuticals, beverages, and foods. They are unaffected by bubbles and changes in fluid composition, ensuring accurate and consistent measurement results.

Environmental Protection Industry

V-cone flowmeters are also widely used in the environmental protection industry, particularly in sewage treatment plants and emission monitoring. Their high accuracy and corrosion resistance enable them to accurately measure the flow of exhaust gases, wastewater, and other fluids.

Energy and Power Industry

In the energy and power industry, V-cone flowmeters are used to measure the flow of steam, cooling water, and various fuels. They are particularly useful for monitoring cooling water flow in power plants and measuring flow in natural gas pipelines, ensuring efficient energy utilization and safe equipment operation.

FAQ

Order Guide

When selecting a V-cone flowmeter, we recommend confirming the following parameters:

- Medium Name:

- Mixed Gas Composition:

- Standard Density:

- Operating Density:

- Minimum Temperature – Normal Temperature – Maximum Temperature:

- Minimum Flow Rate – Typical Flow Rate – Maximum Flow Rate:

- Minimum Pressure – Typical Pressure – Maximum Pressure:

- Regional Atmospheric Pressure:

- Dynamic Viscosity:

- Relative Humidity:

- Inner Diameter – Outer Diameter:

- Material:

- Ambient Temperature:

- Special Requirements

More Flow Measurement Solutions

A V-cone flowmeter is an instrument used to measure the flow of liquids and gases. Its unique design and operating principle have led to its widespread use in industry.

Sino-Inst offers custom V-cone flowmeters, as well as other common differential pressure flowmeters, including orifice flowmeters and Venturi flowmeters. If you require a custom design, please feel free to contact our sales engineers!

-1.jpg)