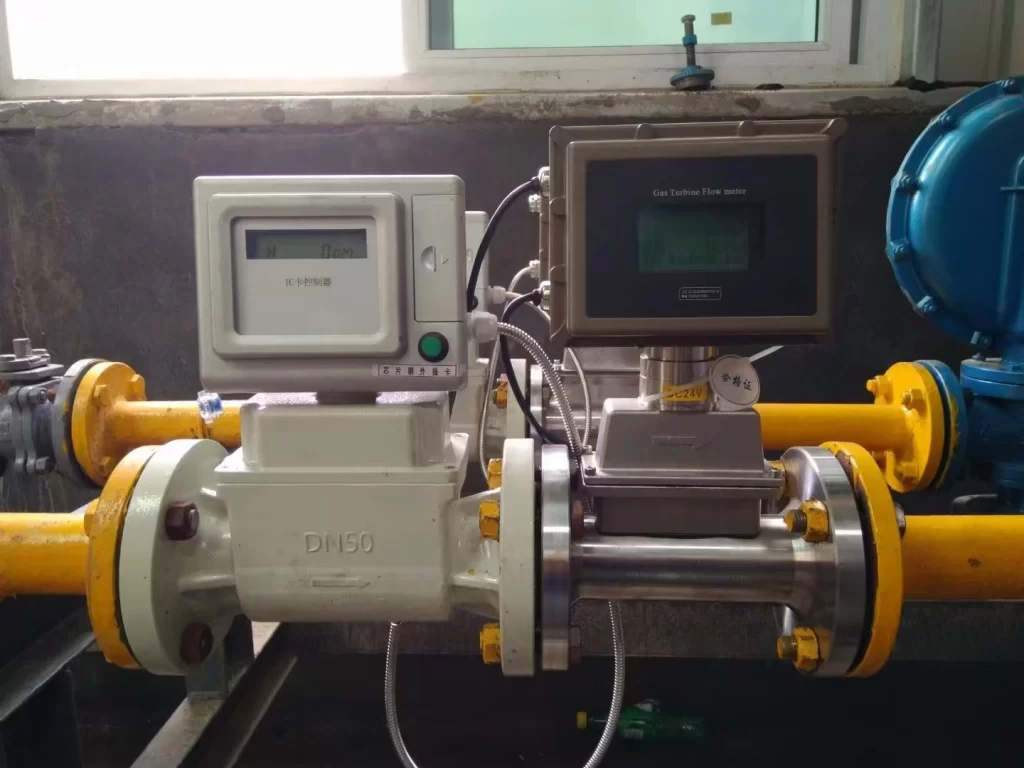

A gas turbine flow meter is a velocity-type flow meter that accurately measures gas flow. It is widely used to measure gases such as natural gas, city gas, propane, butane, air, and nitrogen. With high accuracy and excellent repeatability, it is often used for trade measurement and industrial process monitoring.

The density of gas media varies with temperature and pressure. To ensure accurate measurement, a gas turbine flowmeter simultaneously tracks the temperature and pressure of the media being measured, performing temperature and pressure compensation. It also converts the volume flow rate under different operating conditions to that under standard or agreed conditions.

| Diameter | DN25~DN300 |

| Accuracy | Class 1.0, class 1.5 |

| Protection | IP65 |

| Explosion proof | ExdIIBT6 (explosion proof type) |

| Output | Pulse, 4-20mA analog output,RS485 (Modbus-RTU protocol), HART |

| Medium | ExdIIBT6 (explosion-proof type) |

Features

Specifications

| Item | Data |

| Medium | ExdIIBT6 (explosion-proof type) |

| Accuracy | Class 1.0, class 1.5 |

| Flange | Standard GB/T 9119-2010 |

| Output | Pulse, 4-20mA analog output, RS485 (Modbus-RTU protocol), HART |

| Operation condition | Medium temperature: -30℃~+80℃ |

| Operation temperature: -20℃~+60℃ | |

| Relative humidity: 5%~9% | |

| Atmospheric pressure: 86kPa~106kPa | |

| Ingress protection | IP65 |

| Explosion proof | ExdIIBT6 (explosion proof type) |

| Electrical connection | M20*1.5 |

| Diameter and installation | Flange connection DN25-DN300 |

| Power Supply | a. Internal Instrument Power Supply: One 3.6VDC lithium battery, capable of operating normally between 3.1 and 3.6V; b. Internal GPRS Power Supply: One 6.6VDC lithium battery, capable of operating normally between 5.0 and 6.6V; c. External Power Supply: +24VDC ±15%, ripple ≤±5%, suitable for 4-20mA output, pulse output, RS-485, etc.; d. External (solar) GPRS Power Supply: +5VDC to +7VDC. |

| Power Consumption | External power supply: <1W; internal instrument power supply: average power consumption ≤1mW. Continuous operation for over five years. Internal GPRS power supply: Continuous operation for one to five years, based on the average daily number of calls (2-12). |

Flow Range:

| Model | Nominal Diameter DN(mm) | Flow Range(m3/h) | Max pressure loss (kPa) | Initial flow (m3/h) | Connection type |

| LWQ-25 | 25 | 2.5-25 | 1 | Flange (thread) | |

| LWQ-25 | 4-40 | 2 | |||

| LWQ-40 | 40 | 5-50 | 1.8 | ||

| LWQ-50 | 50 | 6-65 | 0.7 | 2.5 | Flange |

| LWQ-50 | 10-100 | 0.7 | 2.5 | ||

| LWQ-80 | 80 | 13-250 | 0.3 | 6 | |

| LWQ-80 | 20-400 | 0.8 | 6 | ||

| LWQ-100 | 100 | 20-400 | 0.2 | 8 | |

| LWQ-100 | 36-650 | 0.5 | 8 | ||

| LWQ-125 | 125 | 35-700 | 0.5 | 12 | |

| LWQ-150 | 150 | 32-650 | 0.4 | 15 | |

| LWQ-150 | 50-1000 | 1.7 | 15 | ||

| LWQ-200 | 200 | 80-1600 | 0.2 | 35 | |

| LWQ-200 | 130-2500 | 0.9 | 35 | ||

| LWQ-250 | 250 | 130-2500 | 0.2 | 40 | |

| LWQ-250 | 200-4000 | 0.5 | 50 | ||

| LWQ-300 | 300 | 300-6000 | 1.5 | 50 |

Order Guide

| S1–3201 | Note | ||||||

| Diameter | DNXX | DN20–DN150 (mm) | |||||

| Accuracy | A | Class 1.0 | |||||

| B | Class 1.5 | ||||||

| Flow range | S | Standard range | |||||

| E | Extended range | ||||||

| Flange and Housing material | S4 | SS304 | |||||

| S6 | SS316 | ||||||

| Temperature and pressure compensation | A | With temp. and pressure compensation | |||||

| N | Without temp. and pressure compensation | ||||||

| Power supply | 1 | 24VDC | |||||

| 2 | Lithium battery | ||||||

| Output | A | 4-20mA | |||||

| M | Pulse | ||||||

| R | RS485 | ||||||

| H | HART | ||||||

| Explosion Proof | BT | Exd II BT6 | |||||

| CT | Exia II CT4 | ||||||

| NA | None | ||||||

| Connection | THM | Male Thread; Available from DN20-DN50 | |||||

| THF | Female Thread; Available from DN20-DN50 | ||||||

| DXX | DN16:DIN PN16 Flange; | ||||||

| AXX | A15:ANSI 150# Flange; | ||||||

| JXX | J10:JIS 10K Flange; | ||||||

Note for type selection:

Gas turbine flow meter is mainly applicable for intermediate and low velocity gas without impurities. Please install a filter to ensure medium cleaning and note that the product cannot measure moisture. The product is not suitable for liquids and steam.

Type selection process:

Select the main model and structure first, then ensure the other specifications according to requirements.

i.e., main model + nominal diameter + accuracy + installation method + flange and housing material + temperature and pressure compensation + power supply + output.

Featured Applications of Gas Turbine Flowmeters

Natural Gas

As a clean energy source, natural gas holds a vital position in both industrial and civilian sectors. Efficient flow measurement is essential for natural gas trade measurement, transportation, and use. Monitoring pressure and temperature is also essential.

Advantages of using a gas turbine flowmeter for natural gas measurement:

Gas turbine flowmeters offer significant advantages in accuracy, repeatability, zero drift, and rangeability. Their bearings and guide vanes are specially designed to reduce wear, ensuring reliable measurement under challenging conditions.

Gas turbine flowmeters integrate a microprocessor, flow sensor, and high-precision temperature and pressure sensors to directly measure gas flow, temperature, and pressure. They also automatically perform flow tracking compensation and compressibility factor correction.

Other commonly used natural gas flowmeters include gas turbine (Roots) flowmeters and vortex flowmeters.

Read more about:

- Techniques, Importance, and Challenges of Natural Gas Flow Measurement;

- Featured Gas Turbine Flow Meter for Natural Gas and Other Gases;

- Natural Gas Flow Meter Types and Guidelines

Waste Gas Measurement

Renewable resource development is a key path to achieving sustainable development, encompassing multiple sectors, including waste gas recovery, biogas utilization, wastewater treatment, and cogeneration. Accurate gas flow measurement in these processes is crucial for optimizing energy recovery and utilization efficiency, improving treatment outcomes, and ensuring efficient system operation.

In a large-scale waste gas recovery project, precise flow measurement from the waste gas source to the recovery system is required to ensure efficient operation and regulatory compliance.

Gas turbine flowmeters, with their high-precision measurement capabilities, accurately record waste gas flow and transmit this data in real time to a central control system for analysis. Operators use this real-time flow data to adjust waste gas recovery and treatment parameters, optimizing system efficiency, increasing energy recovery and utilization, and reducing operating costs.

Techincal Support

More Feature Flow Measurement Solutions

- 4-20mA Flow Meters | Flow Meter Signal Output Guide

- Analog Flow Meters: An Encompassing Guide

- Industrial Hydraulic Flow Meters | Mechanical & Digital

- RS485 Pressure Sensors

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

- Fluid Flow Sensor | Types and Product List

- What Is Variable Area Flow Meter?

Gas turbine flow meter is a gas turbine flow sensor and electronic volume corrector in one, which can simultaneously detect and display the temperature, pressure, working condition and standard condition flow and total amount of gas.

The product performance is further improved by adopting a number of new technologies such as digital pressure and temperature sensors. It is an ideal instrument for industrial gas detection or measurement in petroleum, chemical, electric power, metallurgy, etc.

Gas Turbine Flow Meters supplied by Sino-Inst are widely used to measure various gases such as natural gas, nitrogen, air, city gas, propane, butane, etc.

If you need to purchase Gas Turbine Flow Meter, or have related technical questions, please feel free to contact our sales engineer!

-1.jpg)