Any polymer compound that can be used as a raw material for plastic product processing is called a resin. Resins typically soften or melt when heated. When softened, they tend to flow under external forces. At room temperature, they are solid, semi-solid, or sometimes liquid.

Resins are diverse and require demanding reaction conditions. The process demands precise measurement of multiple parameters, including temperature, pressure, flow rate, liquid level, material level, pH, conductivity, and vacuum.

Focusing on the typical process of resin technology, we will systematically analyze the application scenarios, selection points, and precautions of various measuring instruments in different links.

Overview of Resin Production Process Measurement Requirements

Resins come in a wide variety of types, including phenolic, epoxy, unsaturated polyester, polyurethane, and acrylic. Their production typically involves the following core processes:

- Raw material storage and feed ratio;

- Premixing and heating;

- Main reaction stage (usually pressurized or depressurized reaction);

- Cooling, degassing, and dilution;

- Filtration and packaging;

Key measurement requirements for each stage are as follows:

| Parameters | Application Purpose |

| Temperature | Control reaction rate to prevent side reactions and thermal runaway; |

| Pressure | Maintain stable pressure in the reactor to avoid overpressure accidents; |

| Liquid level | Control the charging/discharging rhythm to prevent overflow or empty tank operation; |

| Material level | Determine the remaining level in the raw material silo to implement raw material early warning and lean feeding; |

| Flow | Control raw material ratio, solvent addition rate, and finished product metering; |

| Vacuum | Control reaction conditions to promote byproduct removal; |

| pH/conductivity | Monitor neutralization and catalysis processes to ensure reaction completion; |

| Density/viscosity | Assist in determining finished product quality and fluidity. |

Measuring Instrument Types

1. Temperature Measurement

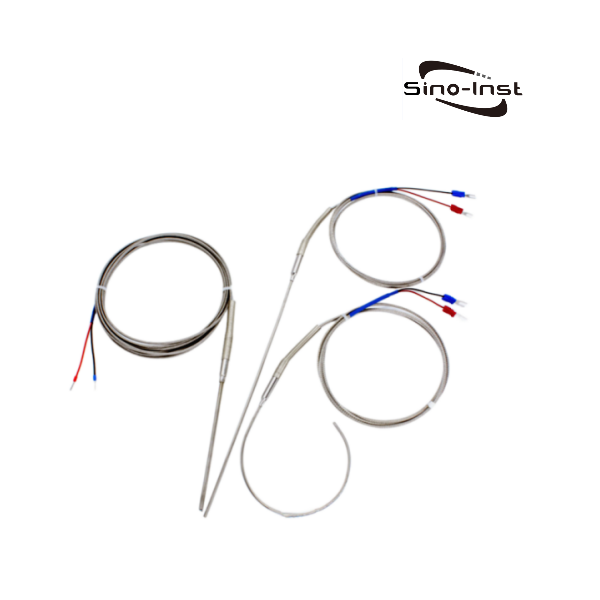

Instrument Types: Thermocouple (K/J type), Platinum RTD (Pt100), Intelligent Temperature Transmitter

Typical Applications: Reactors, jacketed heat transfer units, heaters, and cooler inlet and outlet temperatures

Selection Recommendations:

- Use a corrosion-resistant sheath (such as Hastelloy or PTFE-coated).

- For high-speed stirred tanks, select a temperature sensor with a reinforced protective sheath.

- The temperature range must be 80-300°C to ensure coverage of the entire process curve.

2. Pressure Measurement

Instrument Types: Diffused silicon pressure transmitter, capsule pressure gauge, diaphragm-sealed transmitter.

Typical Applications: Aerator pressure, steam heating pressure, and vacuum system inlet.

Notes:

- For highly corrosive or crystallizing media, a fully welded, corrosion-resistant diaphragm structure is recommended.

- For vacuum control applications, a negative pressure range sensor (e.g., -100 to 0 kPa) is required.

- For media prone to coking, a heated line or purge port can be configured.

3. Liquid Level Measurement

Instrument Types: Radar level meter, magnetic flap level meter, differential pressure level transmitter.

Typical Applications: Reactors, storage tanks, intermediate tanks, buffer tanks

Process Challenges and Solutions:

- For resins with high viscosity and strong foaming properties, radar-based instruments are more adaptable.

- For systems with agitation or bubble disturbances, guided wave radar or float-based instruments are preferred.

- For tanks with high heights and temperatures, an 80GHz high-frequency radar level gauge is recommended to improve resistance to steam interference.

4. Material Level Measurement

In resin production, material level measurement in containers such as raw material silos, solid additive drums, and powder feed silos is used to determine inventory levels, prevent material shortages, and improve material scheduling efficiency.

Common measurement targets:

- Solid powders (such as talc, fillers, and curing agents);

- Small resin particles (such as thermosetting prepolymers);

- Liquid, high-viscosity raw material drums;

For large solid raw material silos, a non-contact radar level meter (with self-cleaning function) is recommended.

For small drums of raw materials, point-level switches (such as low-level alarms) can be used to assist with material early warning within the MES system.

If automation of the feeding process is highly required, a continuous level meter should be selected and interlocked with the DCS/PLC system.

5. Flow Measurement

Instrument Type: Gear flowmeter, Coriolis mass flowmeter

Typical Applications: Raw material conveying lines, solvent dosing lines, product filling lines

For low-viscosity liquids (such as monomers and solvents), electromagnetic or turbine flowmeters are recommended.

For high-viscosity, high-temperature fluids (such as reactants and resin slurries), mass flowmeters are preferred.

For highly corrosive media, flowmeters lined with PTFE or PFA are recommended.

More Measurement Solutions

Resin, as an important organic synthetic material, is widely used in various fields of modern industry. Measuring instruments can effectively monitor the production and application of resins in real time, helping to improve production efficiency and reduce costs.

Sino-Inst supplies pressure, level, flow, temperature, and other measurement and control instruments. If you require measurement of resin-related parameters, please feel free to contact our engineers!

-1.jpg)