Electromagnetic flowmeter is suitable for volume flow measurement of various conductive liquid media. The only media contact parts are the electrode and the lining of the measuring tube. According to the characteristics of different media, select the Magnetic Flow Meter Lining Material and electrode material. It can effectively improve the service life and measurement accuracy of the electromagnetic flowmeter.

Featured Magnetic Flow Meters

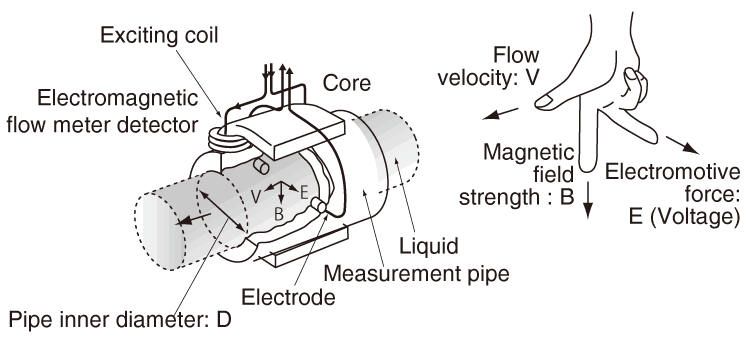

Structure of electromagnetic flowmeter

Electromagnetic flowmeter (EMF for short) is an instrument made by using Faraday’s law of electromagnetic induction to measure the volume flow of conductive liquid. Conductive fluid flow is measured based on the electromotive force induced when the conductive fluid passes through an external magnetic field.

The structure of the electromagnetic flowmeter mainly consists of magnetic circuit system, measuring conduit, electrode, shell, lining and converter.

Magnetic circuit system: Its function is to generate a uniform DC or AC magnetic field. The DC magnetic circuit is implemented with permanent magnets. Its advantage is that the structure is relatively simple and it is less disturbed by the AC magnetic field. But it tends to polarize the electrolyte liquid passing through the measuring catheter. The positive electrode is surrounded by negative ions, and the negative electrode is surrounded by positive ions, which is the polarization phenomenon of the electrode. It also causes the internal resistance between the two electrodes to increase, thus seriously affecting the normal operation of the instrument. When the diameter of the pipe is larger, the permanent magnet is correspondingly larger. It is bulky and uneconomical, so electromagnetic flowmeters generally use alternating magnetic fields and are generated by 50HZ power frequency power supply.

Measuring catheter: Its function is to allow the conductive liquid to be measured to pass through. In order to cause the magnetic flux to be shunted or short-circuited when the magnetic field lines pass through the measuring conduit, the measuring conduit must be made of materials that are non-magnetic, have low electrical conductivity, low thermal conductivity and have certain mechanical strength. Non-magnetic stainless steel, fiberglass, high-strength plastic, aluminum, etc. can be used.

Electrode: Its function is to elicit an induced potential signal that is proportional to the measured value. The electrodes are generally made of non-magnetic stainless steel. and are required to be flush with the lining so that fluid can pass through unimpeded. Its installation position should be in the vertical direction of the pipe. To prevent sediment from accumulating on it and affecting the measurement accuracy.

Shell: Made of ferromagnetic material, it is the outer cover of the excitation coil of the distribution system and isolates the interference of the external magnetic field.

Lining: There is a complete electrically insulating lining on the inside of the measuring conduit and on the flange sealing surface. It directly contacts the measured liquid, and its function is to increase the corrosion resistance of the measuring tube and prevent the induced potential from being short-circuited by the metal measuring tube wall. Lining materials are mostly corrosion-resistant, high-temperature-resistant, wear-resistant polytetrafluoroethylene plastics, ceramics, etc.

Converter: The induced potential signal generated by the liquid flow is very weak and is greatly affected by various interference factors. The function of the converter is to amplify and convert the induced potential signal into a unified standard signal and suppress the main interference signal. Its task is to amplify and convert the induced potential signal Ex detected by the electrode into a unified standard DC signal.

Read More About: Magnetic Flowmeter Technology

In an electromagnetic flowmeter, the only parts in contact with the medium are the electrodes and the inside of the measuring tube. Therefore, it is necessary to choose the correct electrode and lining materials according to the characteristics of different media.

Magnetic Flow Meter Lining Material selection

| Lining material | Linner | Main performance | Application | Diameter |

| Rubber | Neoprene(CR) | 1. It has excellent flexibility. High tearing force. Good wear resistance. 2. Resistant to the corrosion of low-concentration acid, alkali, and salt media. Not resistant to corrosion by oxidizing media. | 1. <60℃ 2. General water, sewage, mud and mineral slurry with weak abrasiveness | DN65~DN1600 |

| Polyurethane Rubber(PU) | 1. It has excellent wear resistance (equivalent to ten times that of natural rubber) 2. Poor acid and alkali resistance. 3. It cannot be used for water mixed with organic solvents. | 1. <80℃ 2. Neutral and strong abrasion ore slurry, coal slurry, mud, etc. | DN25~DN500 | |

| Silicone rubber | 1. It has excellent flexibility. High tearing force. Good wear resistance. 2. High temperature resistant non-corrosive medium. | 1. <180℃ 2. Hot water | DN40~DN1600 | |

| Fluoroplastics | PTFE(F4) | 1. It is a material with the most stable chemical properties in plastics. Can withstand boiling hydrochloric acid, sulfuric acid, nitric acid and aqua regia. It is also resistant to concentrated alkali and various organic solvents. Not resistant to the corrosion of chlorine trifluoride, high temperature oxygen trifluoride, high flow rate liquid fluorine, liquid oxygen, and ozone. 2. Poor wear resistance. 3. Poor anti-negative pressure ability. | 1. <120℃ 2. Strong corrosive media such as concentrated acid and alkali 3. Sanitary medium | DN10~DN1600 |

| Teflon F46(FEP) | 1. The chemical properties are equivalent to PTFE 2. Tensile strength and abrasion resistance are better than PTFE 3. Can withstand high pressure resistance. | 1. <180℃ 2. Corrosive acid-base salt 3. High pressure and negative pressure resistance | DN10~DN200 | |

| PFA | 1. The chemical performance is equivalent to F46 2. Compressive and tensile strength due to F46 | 1. <180℃ 2. Corrosive acid-base salt 3. High pressure and negative pressure resistance | DN10~DN300 |

Magnetic Flow Meter Electrode material selection

| Material | Medium |

| 316L | Domestic water, industrial water, raw water, urban sewage, etc. |

| Hastelloy B (HB) | Sodium hydroxide ammonium hydroxide alkali solution and weak organic acid |

| Hastelloy C (HC) | Oxidizing salt solution (Fe+++, Cu++, seawater) |

| Titanium (Ti) | 1. Salt solution (chloride, sodium salt, potassium salt, ammonium salt, sea water, etc.) |

| 2. Alkaline solution (such as concentration less than 50% potassium hydroxide solution) | |

| Tantalum(Ta) | 1. Hydrochloric acid, sulfuric acid, oxidizing acid, aqua regia |

| 2. Chlorine dioxide, ferric chloride, hypochlorous acid, sodium cyanide, lead acetate, etc. | |

| Platinum (Pt) | Acid, alkali, salt solution |

| Tungsten carbide (WC) | Handled neutral industrial sewage and domestic sewage. Resistant to solid particle interference |

In addition to the chemistry of the medium and the requirements of the measurement environment, there are other factors to consider in material selection. Such as material stability, mechanical strength, cost, processing difficulty, durability, etc. All need to be considered comprehensively in practical applications.

In addition, attention should be paid to possible electrochemical reactions between different electrodes and lining materials. This may have an impact on the measurement results. Electrochemical reactions between different materials should be avoided as much as possible.

More Electromagnetic Flowmeter Applications Guide

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Electromagnetic High Pressure Flowmeter | 0.6MPa-1.6MPa-6.3MPa-16MPa-25MPa-35MPa-42MPa

- Application of Electromagnetic Flowmeter in Paper Mill Slurry Wastewater Treatment System

- Brewery Flow Meters for Beer and Wine | Electromagnetic and More

- What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

- Magnetic Flow Meter Troubleshooting| Manufacturer’s Guide

- Installation Instructions for Electromagnetic Flowmeters

- Digital Water Flow Meter

- Sanitary Flow Meter

- Wastewater flow meter

- Water Flow Meter Types

Electrodes and linings are key components of electromagnetic flowmeters. Correct material selection can effectively improve the service life and measurement accuracy of electromagnetic flowmeters.

When selecting materials, comprehensive considerations need to be made based on various factors such as the chemical properties and corrosiveness of the medium, the requirements of the measurement environment, mechanical properties, and cost.

In practical applications, we should choose the material that best suits our application needs to obtain more accurate, reliable and stable measurement results.

If you need to purchase an electromagnetic flowmeter and don’t know how to configure it. Please contact our engineers!

-1.jpg)