In today’s industrial process measurement and control, real-time monitoring is essential for continued operation. The HART (Highway Addressable Remote Transducer) protocol has become an indispensable answer to achieving these goals.

This blog explores how the HART communication protocol works and its application in critical process measurements. The focus will be on the benefits it brings to industrial automation and control.

What is HART Protocol?

The HART Communication Protocol is a hybrid analog+digital industrial automation open protocol. HART is a bi-directional communication protocol that renders data access between intelligent field instruments and host systems.

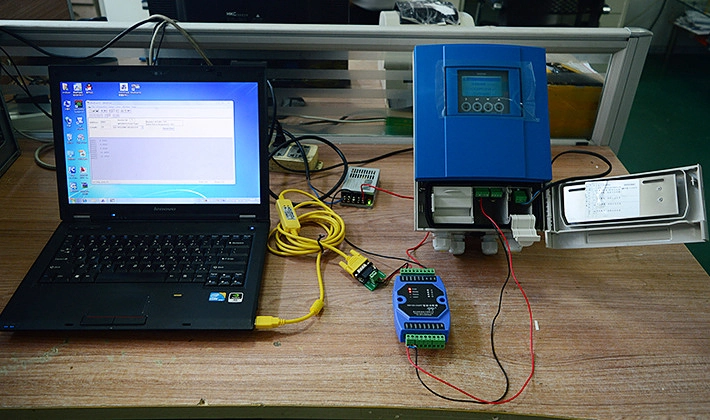

A host can be any software application from technician’s hand-held device or laptop to a plant’s process control. Communication occurs between two HART-enabled devices, typically a smart field device and a control or monitoring system. Instrumentation grade wiring and standard termination practices guarantee trustworthy communication.

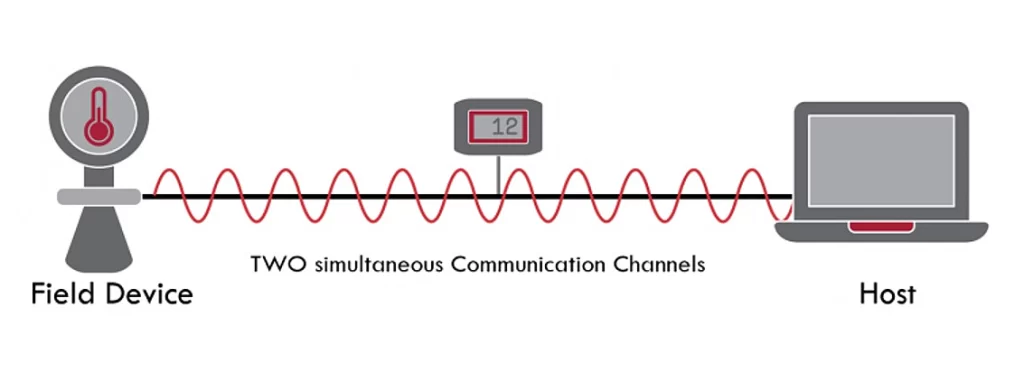

HART provides two concurrent communication channels, one analog, the other digital.

A 4-20mA signal communicates the primary measured value (PV) as an analog value of current using the wiring that provides power to the instrument.

The host system then converts the current value to a physical value according to parameters defined by HART Software.

How HART Works: It’s Working Principle

The HART protocol uses the frequency shift keying (FSK) standard to superimpose a low-level digital communication signal on top of the 4-20mA. Two-way field communication is possible. And other information besides normal process variables can be transmitted to/from smart field instruments.

The HART protocol provides two simultaneous communication channels: 4-20mA analog signal and digital signal. The 4-20mA signal uses the 4-20mA current loop to transmit the primary measurement value (for field instruments). Additional device information is transmitted using a digital signal superimposed on the analog signal.

Benefits of HART Protocol

Key Process Managements and HART Technology Utilization and Advantages

HART Pressure Transmitters and DP Transmitters

A HART pressure transmitter is an instrumentation used to measure pressure in a process environment. It converts pressure into a standard analog signal (4-20 mA) and at the same time transmits real-time pressure data using the HART protocol.

Sino-Inst’s Industrial HART pressure Transmitter and DP transmitter:

Utilization:

HART pressure transmitters are extensively used in industries like oil & gas, water treatment, and manufacturing. They measure pressures in liquids, gases, and steam in process pipelines, storage tanks, and pressure vessels. The ability to transmit digital data allows operators to remotely monitor pressure changes, diagnose issues, and ensure system integrity.

Advantages:

- Accuracy and reliability: HART pressure transmitters offer high levels of precision, helping operators maintain safe and efficient operations.

- Remote monitoring and configuration: Operators can adjust settings and monitor pressure levels from a central location, reducing the need for manual intervention in hazardous or hard-to-reach areas.

- Diagnostics: HART-enabled pressure transmitters can send diagnostic alerts, such as sensor drift, to prevent failures and costly downtimes.

HART Temperature Transmitter

A Field HART temperature transmitter is an electronic device that converts and displays the temperature of a fluid. These transmitters are designed for industrial applications, typically installed inside or outside of a factory or in hazardous environments, and feature advanced technology.

Utilization:

A HART temperature transmitter is used in industrial processes to accurately monitor and control temperatures.

Advantages:

- High precision

- Data transmission

- Remote diagnostics

HART Level Transmitter

HART liquid level transmitters for configuration via a distributed control system (DCS) or HART communicator. HART liquid level transmitters are matched with the HART communication protocol which is the most popular standard used with smart field devices by the process control industry.

HART functionality enables the transfer of liquid-level transmitter data via an AC digital signal which uses the 4-20mA analog output signal as a carrier, thus eliminating the need for extra wires and connectors.

Utilization:

- Tank level monitoring: HART level transmitters ensure optimal inventory management and prevent overflow in a storage tank.

- Interface measurement: HART level transmitters can measure the interface between layers, where different fluids (e.g., oil and water) form layers.

- Open channel flow measurement: In water treatment plants, HART level transmitters are used to monitor water levels in open channels or reservoirs.

HART Flow Meter

A HART flow meter measures the flow rate of liquids, gases, or steam in a process. Using the HART protocol, the flow meter communicates real-time flow data to a control system, enabling more efficient and accurate process control.

Types of HART Flow Meters:

Coriolis flow meters: Coriolis flow meters allow the direct measurement of mass flows. Direct mass flow measurement eliminates inaccuracies caused by the physical properties of fluids.

Vortex flow meters: A vortex meter is a type of volumetric flow meter that makes use of a natural phenomenon that occurs when a liquid flows around a bluff object. Vortex flow meters are best suited for flow measurements where the introduction of moving parts presents problems. They are available in industrial grade, brass, or all plastic construction.

Ultrasonic flow meters: Ultrasonic flow meters, which are a type of volumetric flow meter, are non-intrusive flow sensors that use acoustic vibrations to measure the flow rate of a liquid. There are two types, Doppler and transit time

Magnetic flow meters: Magnetic flow meters, also known as electromagnetic flow meters, are often selected because they are obstructionless, cost-effective, bi-directional, and provide highly accurate volumetric flow measurements.

Utilization:

- Process control: HART flow meters are widely used in industries such as oil & gas, pharmaceuticals, food and beverage, and water treatment for monitoring and controlling the flow of fluids.

- Custody transfer: Flow meters are critical for accurate measurement in transactions where fluids like natural gas or oil are transferred between parties.

- Energy management: In HVAC systems, flow meters monitor the flow of steam or chilled water to optimize energy use and improve system efficiency.

More Process measurement and control solutions

- Featured Gauge Pressure Transmitters for Industrial Process Pressure Measurement

- Everything You Need To Know About Chemical Flow Meters

- Boat Fuel Flow Meters: Installation Tips and Comparability

- Platinum Resistance Thermometer: PT100 vs PT1000

- An All-inclusive Guide on Crude Oil Measurement

- Industrial Refrigerant Flow Meters

- Getting to Know The Propane Flow Meters: Better Monitoring of Propane Utilization

- What Are Diaphragm Seal Systems in Pressure Measurement? and Types

- Importance of Digital Fuel Flow Meters and Fuel Oil Flow Meters in Modern-day Industrial Applications

The HART Protocol is a powerful communication technology used to employ the full potential of smart field devices. Preserving the traditional 4-20mA signal, the HART Protocol extends system capabilities for two-way digital communication with smart field instruments.

The HART Protocol offers the most cost-effective solution for smart field device communication and has the widest base of device suppliers and device types of any field device protocol worldwide.

Sino-Inst produces and supplies various process instruments. HART protocol can be configured. If you need to purchase or have related questions. Please feel free to contact our sales engineers!

-1.jpg)