The chemical flow meter refer to flow meters that measure both corrosive and non-corrosive gas and liquid passing through them. Measuring the flow rate of liquids is necessary for controlling and checking the quality of industrial chemical processes. It assures accuracy in fluid quantity and quality.

Let’s explores the various types of Chemical flow meters and the general selection criteria. We will also cover topics such as chemical flow meters for liquids, chemical-resistant flow meters, and chemical injection flow meters to provide a broad perceptive of these critical instruments.

What is a flow meter in chemical industry?

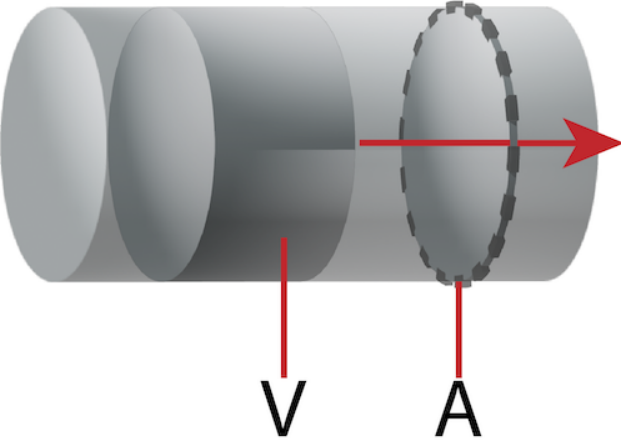

The flow rate in a chemical flow meter is the amount of fluid (In Figure labeled V) that passes through a particular area (In Figure labeled A) within a given period.

It quantifies the fluid’s three-dimensional space as it flows through the device. Divide the fluid volume by the time it takes to pass through to get the volumetric flow rate.

Of course, we can also require measurement of mass flow rate.

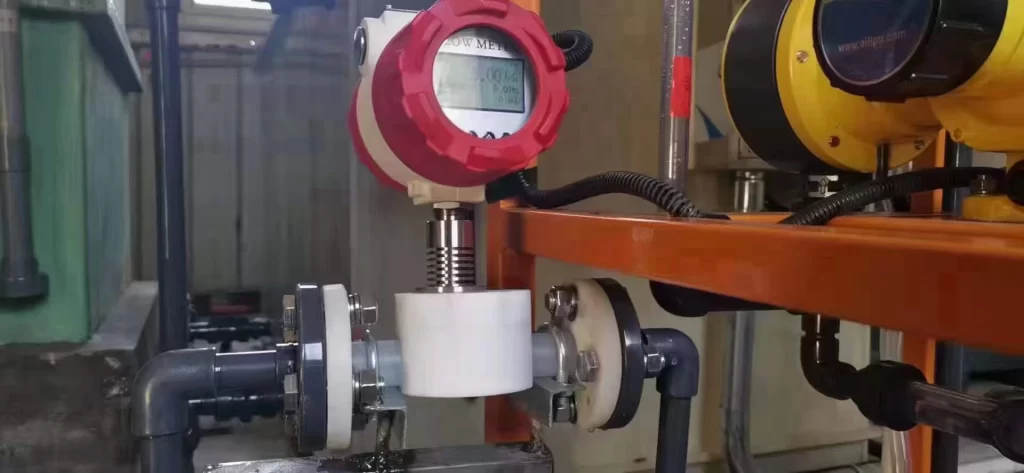

Chemical flow meters may use various technologies such as ultrasonic, electromagnetic, thermal mass measurement or Coriolis force to accurately measure flow.

Compared with flow meters used in other industries. Flow meters in the chemical industry are able to handle a variety of chemicals. Including corrosive substances and high viscosity liquids, making them suitable for various applications in the chemical industry.

Benefits of Chemical Flow Meters

Flow meters play an important role in continuous and batch chemical processes. Maintain efficient and consistent operation of the process.

- Use flow meters to maintain a constant flow of fluids. For example, in the production of pharmaceuticals, control the flow of reactants to improve product compliance.

- Accurately control the flow in batch production. For example, in the production of polymers, flow controllers can be used to control the flow of monomers during polymerization.

- Special flow meters such as high temperature and high pressure can be customized. Ensure that the final product meets the specifications and the process runs effectively.

- Effectively monitor the flow. Most flow meters have functions such as diagnosis, instantaneous flow, cumulative flow, and signal output.

- For quantitative control, filling and other processes, flow meters can be used to accurately measure and control small flow liquids and gases. Provide high accuracy and high repeatability.

Types of Chemical Flow Meters with their applications

| Types | Overview | Applications |

| Magnetic Flow Meters | Magnetic flow meters take advantage of Faraday’s law of electromagnetic induction. This flow meter creates a magnetic field. When conductive fluid flows through the magnetic field, an electromotive force (voltage) proportional to the flow rate is produced. They have relatively small pressure drops. | These flow meters are best for conductive fluids like water, wastewater, and chemicals.Compatible with highly corrosive fluids, making them an excellent choice for a ‘chemical-resistant flow meter’ |

| Positive displacement (PD) flow meters | They measure flow by trapping a fixed volume of fluid and counting the number of times the chamber fills and empties. PD meters are often used when accuracy is more important than speed. | Ideal for ‘chemical feed flow meters’ where precise dosing is required, Used in the pharmaceutical and cosmetics industries, Suitable for measuring additives and other chemicals in water treatment plants |

| Coriolis flow meters | Coriolis flow meters are among the most precise flow measurement devices, suitable for handling various chemicals, including highly viscous fluids. These meters work by measuring the mass flow rate of a liquid or gas using the Coriolis effect. When a fluid passes through a vibrating tube, the meter measures the twist or deflection to determine the flow rate. | Useful for chemical injection systems, High-precision dosing of chemicals, Suitable for corrosive and aggressive chemicals |

| Turbine flow meters | Turbine flow meters are a popular choice for measuring clean and stable fluids. A rotor inside the flow meter spins as the fluid flows through it, and the rotational speed is proportional to the flow rate. They are less suitable for highly viscous or dirty fluids but are excellent for non-corrosive liquids. | Used in monitoring and controlling chemical dosing in water treatment plants, Suitable for chemical pump flow meters in non-corrosive environments, Often used in chemical injection flow meter systems for additives |

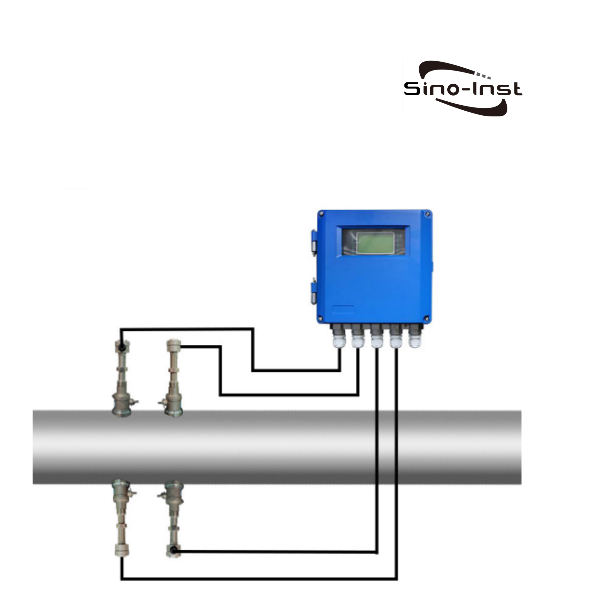

| Ultrasonic flow meters | Ultrasonic flow meters transmit ultrasonic signals through the media to measure the time necessary for the signals to travel upstream and downstream. The transit time difference allows for calculating the flow rate. | These meters are non-intrusive and are suitable for a variety of fluid types, Excellent for corrosive and high-purity chemical applications, A good option for ‘chemical injection flow meters’ where contact with chemicals is undesirable |

| Vortex flow meters | Vortex flow meters use the von Kármán effect. Vortex flow meters measure flow based on the principle of vortex shedding. Within the meter is a blunt, raised area. As the fluid flows past this area, alternating vortices are created. A flexible sensor tab in the flow meter bends and flexes to measure the frequency of the vortices. The frequency of vortices is proportional to the flow rate. | Used in chemical plants where steam or gas flow needs to be measured, Suitable for monitoring ‘chemical feed flow meters’ in industrial processes, Effective for liquids that have low to moderate viscosityThese flow meters are highly accurate and suitable for a range of fluids. |

Selection criteria of a Chemical flow meter

Consider the following general criteria while selecting a Chemical flow meter:

More Featured Flow Measurement Solutions

- Guide To Vortex Flow Meters For Steam Applications: Steam Vortex Flow Meter In detail

- Featured Gas Turbine Flow Meter for Natural Gas and Other Gases

- Mechanical Oil Flow Meter vs Digital

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

- Electronic Flow Meters-Digital Display

Sino-Inst is a reliable company, which is capable of supporting businesses in maintaining efficiency and enhancing their operational standards with suitable chemical flow meters.

Choosing the right chemical flow meter can help the chemical industry optimize operations, safety, and efficient production. Whether you are looking for a “chemical injection flow meter”, “chemical resistant flow meter” or “chemical feed flow meter”, understanding the different types of meters available will help you make an informed decision.

If you need to purchase a chemical flow meter, or have related technical questions, please contact our engineers!

-1.jpg)