From extraction to use, natural gas undergoes long pipeline transportation, filtration, storage, and pressure regulation. Monitoring pipeline pressure during these processes is crucial to ensuring proper system operation.

Natural gas pressure transmitters are designed to accurately measure a variety of gas pressures. Low and high pressures, gauge pressure, absolute pressure, and differential pressure can all be customized. They are equipped with 4-20mA, 0-5V, RS485, and HART outputs and meet Ex db IIC T6 Gb and Ex tb IIIC T80°C Db explosion-proof ratings.

Benefits of Natural Gas Pressure Transmitters

Natural gas is an important clean energy source, but it is also a dangerous, flammable, and explosive gas. During pipeline transportation and tank storage, pressure monitoring provides real-time information on natural gas conditions.

- At the production site, pressure sensors accurately monitor downhole pressure changes to prevent blowouts.

- During pipeline transportation, pressure monitoring can detect and prevent natural gas leaks and failures.

- The signal output of natural gas transmitters facilitates remote monitoring.

- During the storage and transportation of oil and natural gas, pressure transmitters can be used to monitor pressure changes within tanks or storage facilities to ensure safe transportation and storage.

Sino-Inst provides high-precision, high-stability, explosion-proof, and customizable pressure sensors for reliable pressure monitoring in natural gas pipelines.

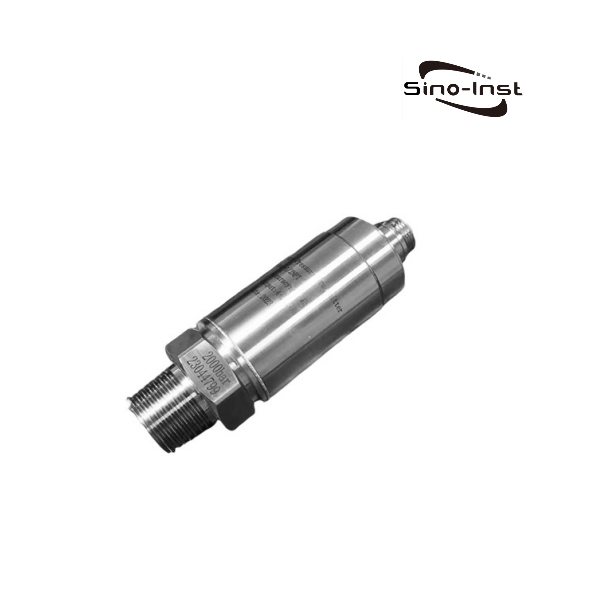

Featured Products

Selecting a Natural Gas Pressure Transmitter

When choosing a suitable natural gas pressure transmitter, we need to consider the following key factors:

- Explosion-proof Safety

Natural gas is primarily composed of methane. Natural gas is flammable and explosive. The explosive limit in air is generally between 5% and 15% (depending on the natural gas composition). When the gas mixture reaches the explosive limit, it will explode upon contact with an ignition source.

Therefore, a pressure transmitter with explosion-proof certification is essential. Common explosion-proof ratings include Exia and Exd. Explosion-proof pressure transmitters use a special housing structure to prevent sparks or high temperatures from igniting the internal circuitry in explosive atmospheres, thereby ensuring safety.

- Signal Output

Pressure transmitters detect natural gas pressure and convert the pressure signal into a standard electrical signal. This signal is used for remote output, enabling monitoring in a control room or data acquisition system.

Commonly used signals include 4-20mA and 0-5V. These are analog signals that are linearly proportional to the pressure range.

Digital signals are also available, such as RS485 and HART protocols.

Currently, a small number of wireless output signal types exist, such as 4G, LORAWAN, and GPRS. It is believed that wireless natural gas pressure transmitters will become more widely used in the future.

- Pressure Range

The pressure range of a natural gas pressure transmitter can be customized based on the measurement point.

During natural gas transportation, the delivery pressure must be maintained. While the delivery pressure should not be excessive, it must be stable. For example, low-pressure measurements below 1 bar are possible.

When natural gas is consumed, typically in industrial burners, boilers, or furnaces, low inlet pressures must also be controlled to ensure safe and efficient operation.

Of course, there is also a need for high-pressure measurement, especially during natural gas storage. Storage differs from transportation. Natural gas is typically compressed during storage, such as in natural gas storage cylinders or tanks. This process can involve pressures of tens or even hundreds of MPa.

High-pressure measurement is also necessary for other high-pressure transmission pipelines or wellhead pressures during production.

- Material Compatibility

Material compatibility is also important, as natural gas may contain moisture or corrosive impurities. For example, hydrogen sulfide (H2S). The sensor diaphragm and threads of a pressure transmitter come into contact with the measured gas. We typically use 316 stainless steel. For more corrosive applications, we also offer special materials such as Hastelloy and Monel.

- Mounting Dimensions

Pressure transmitters are typically threaded or flange mounted. They can also be integrated or remotely mounted.

Common threads such as M20*1.5, 1/2NPT, and special threads such as AN4 (AS4395E-04) 7/16-20 UNF with 37° flare can all be customized.

Flanges can also be customized to meet specific requirements, including ANSI, JIS, and DIN flanges.

More Natural Gas Monitoring Solution

In addition to natural gas pressure sensors, Sino-Inst also supplies other sensors for monitoring natural gas flow and temperature.

Pressure transmitters monitor natural gas pressure in pipelines and equipment in real time, monitoring equipment operation. They are used for pressure monitoring and leak detection systems at regulating stations, custody transfer points, gas skids, and CNG filling stations.

Sino-Inst is a professional supplier of natural gas pressure transmitters. We support customization of various measurement parameters, including high pressure, low pressure, high temperature, special materials, special sizes, and more. If you need natural gas pressure measurement, please feel free to contact our sales engineers!

-1.jpg)