The occurrence of leaks puts businesses at high risk. Therefore, effective preventive measures are necessary. Ultrasonic technology is an efficient leak detection method. Ultrasonic flow meters detect leaks by non-invasively measuring fluid flow.

This technology covers a variety of liquids and pipe materials. It is suitable for crude oil transportation, chemical production, and energy pipeline networks. In industrial plants, it can be used for targeted detection of leak-prone areas such as valves and flanges.

What is an Ultrasonic Flow Meter?

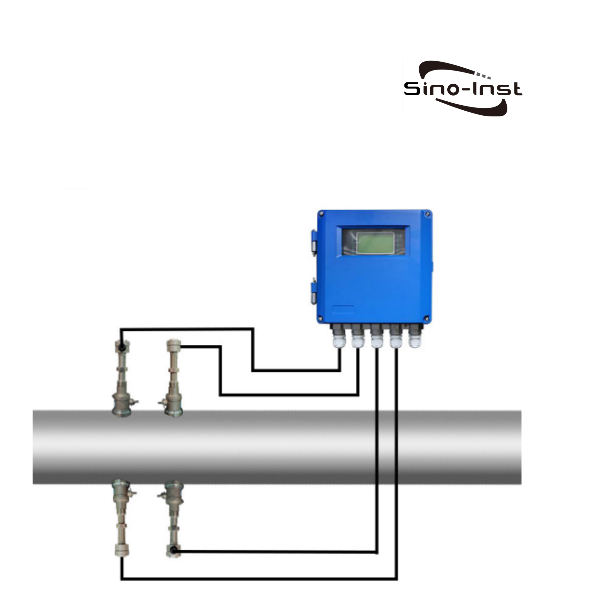

An ultrasonic flowmeter is a non-contact flow measurement instrument. It utilizes the propagation characteristics of ultrasonic waves in fluids to indirectly measure the velocity and flow rate of fluids within pipelines.

Ultrasonic flowmeters require no pipeline interruption and no contact with the medium. They transmit and receive ultrasonic signals via external sensors. These devices can precisely calculate both the instantaneous flow rate and cumulative flow of fluids.

Leak Detection Methods

Flow Balance Method

Under normal conditions, the inflow and outflow of liquid in a pipeline should be balanced. A leak will disrupt this balance. By comparing the difference between the inlet and outlet flow rates, the presence of a leak can be determined.

Abnormal Signal Detection Method

When a leak occurs in a pipeline, the leak point will generate additional ultrasonic signals. The sensors of an ultrasonic flow meter can detect these abnormal signals.

How to Locate a Water Leak Using an Ultrasonic Flow Meter?

Detailed Steps:

1. We need to locate a straight section of pipe and install the transducer non-invasively on the pipe’s outer wall. Input the pipe specifications and measure flow rates at various locations. During installation, ensure the transducer is properly coupled to the pipe surface.

2. Ultrasonic Signal Transmission and Acquisition. The transducers transmit ultrasonic pulses towards each other. The system measures the time difference of sound wave propagation. The data acquisition module captures the received signal in real time.

The time-of-flight method is based on the formula: Δt = (2L/v) × (v/c²) × sin²θ.

L is the sound path length. v is the flow velocity. c is the speed of sound. θ is the angle between the sound path and the pipe axis.

3. Leakage Characteristic Signal Extraction. When the liquid flows normally, the time difference between the downstream and upstream sound waves is stable. When a leak occurs, a sudden change in local pressure in the pipe generates a negative pressure wave. This causes abnormal sound wave propagation.

The acquired signals are pre-processed. The original signal frequency is adjusted to the range of 1-10 to meet the input requirements of the chaotic algorithm.

4. Leakage Localization and Calculation. The chaotic algorithm module analyzes the signal phase and amplitude changes to determine the leak point. The phase difference is calculated using a phase-locked loop method. The amplitude difference is based on the peak vector synthesis of the chaotic oscillator.

Localization accuracy is determined by back-calculating from the time difference. The formula is: x = (c × Δt × L) / (2v × T). x is the distance of the leak point from the upstream transducer. T is the round-trip time of the sound wave.

5. Data Processing and Alarm. The processed data is converted into binary files through the VXD driver. They are stored in the MS SQL Server database. If an abnormal signal is detected, the sound and light alarm circuit is triggered.

Important Notes: This method is suitable for cleaning liquid pipelines. If the medium contains excessive gas content or particulate matter, a Doppler ultrasonic flowmeter must be used.

Benefits and Considerations for Ultrasonic Flow Meters in Leak Detection

Benefits

Non-contact measurement. Ultrasonic flow meters do not require direct contact with the fluid being measured. This avoids damage to the measuring equipment caused by the properties of the fluid.

High accuracy and stability. Ultrasonic flow meters can achieve extremely high measurement accuracy. They also exhibit excellent long-term stability. This is crucial for leak detection.

Wide applicability. Ultrasonic flow meters are suitable for a variety of fluid media, including different liquids and different pipe sizes and materials. This allows them to be widely used in various industrial environments.

Easy installation and maintenance. Ultrasonic flow meters are easier to install. They do not require cutting the pipe or complex installation procedures. Furthermore, due to their non-contact design, maintenance costs are relatively low.

Considerations

- Ultrasonic flowmeters have weak resistance to noise and interference. Therefore, interference sources should be avoided as much as possible during use to ensure measurement accuracy.

- The characteristics of the fluid being measured also affect the accuracy of the ultrasonic flowmeter. Therefore, the fluid should be tested before using the ultrasonic flowmeter, and a suitable flowmeter model should be selected based on the test results.

- Ultrasonic flowmeters cannot measure zero flow (such as when the pipe is disconnected). Therefore, this situation must be avoided during installation.

FAQ

More Flow Measurement Solutions

Case: Non-Contact Ultrasonic Flow Meter For Water

Ultrasonic Flow Meter for Water and Other Liquids

Quick Guide: Clamp on Ultrasonic Flow Meter Installation

Ultrasonic vs Magnetic Flow Meter: Analyze and Help You Choose

Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

Ultrasonic Flow Meters: Doppler Effect vs Transit Time

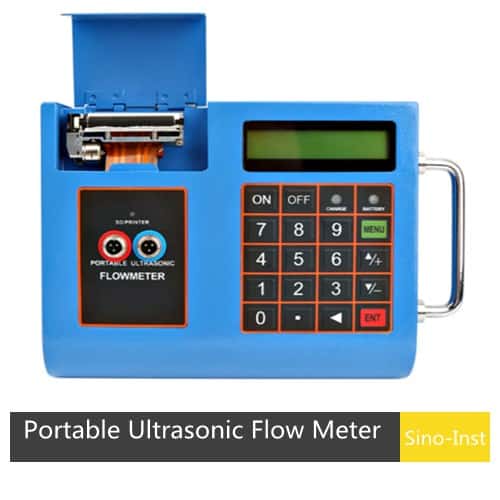

Ultrasonic flow meters have several successful applications in liquid pipeline leak detection. They are widely used and suitable for pipes of various sizes and materials, especially for measuring flow in large-diameter pipes. The advantage of portable ultrasonic flow meters lies in their non-invasive design. This means that installation does not require cutting the pipe or interrupting the flow of liquid.

Ultrasonic flow meters offer high accuracy, strong reliability, and a wide measurement range. Therefore, ultrasonic flow meters are the preferred choice for leak detection. Sino-Inst offers a variety of ultrasonic flow meters, including clamp-on and Doppler ultrasonic flow meters. If you need an ultrasonic flow meter or have any questions regarding leak detection, please feel free to contact our sales engineers!

-1.jpg)