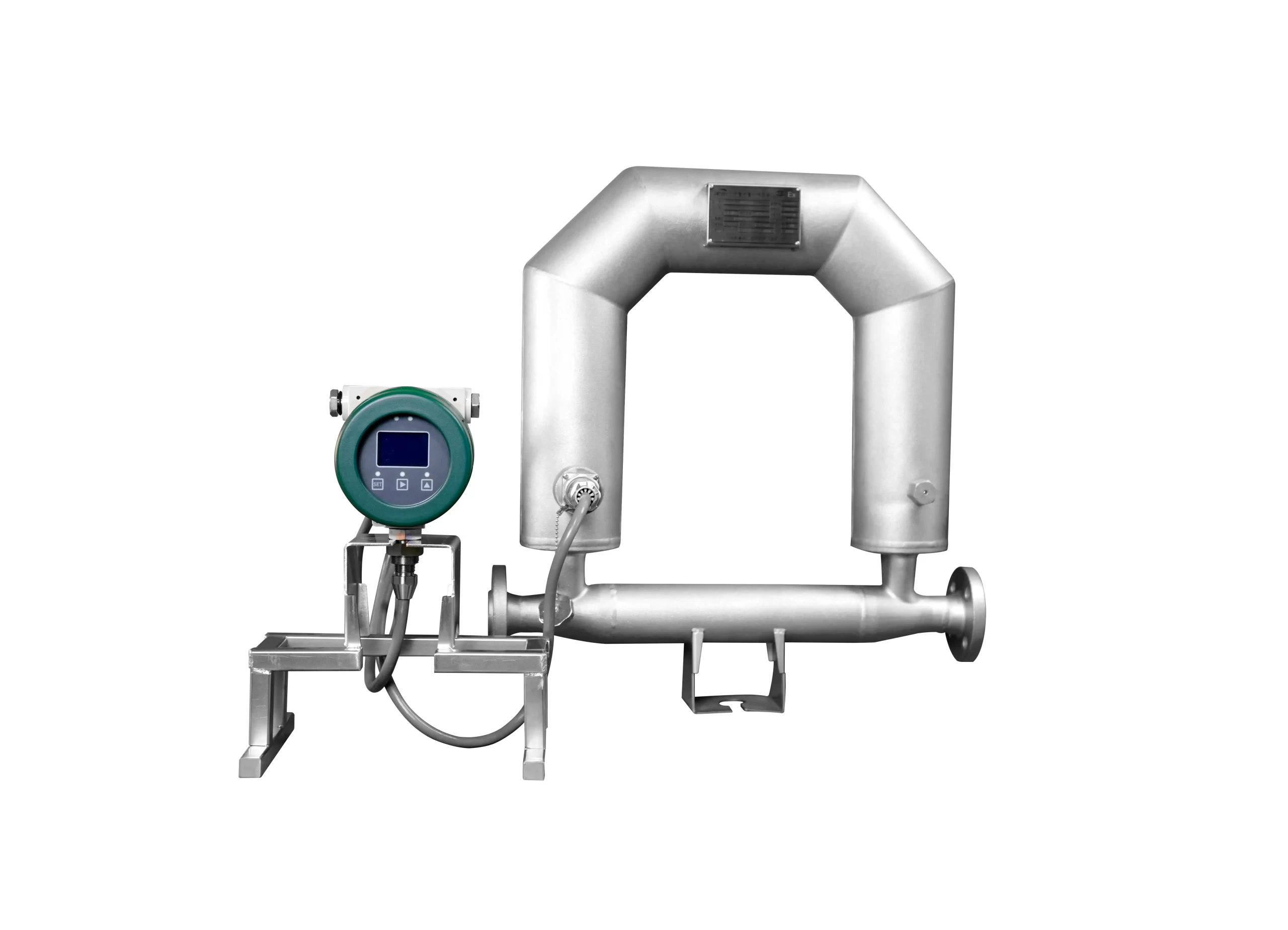

U series Coriolis flow meter – for mass, volume, temperature and density measurement.

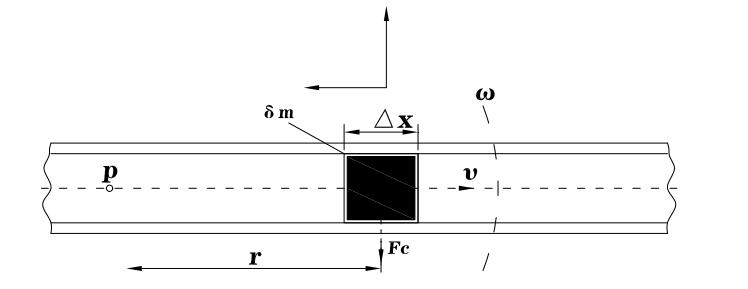

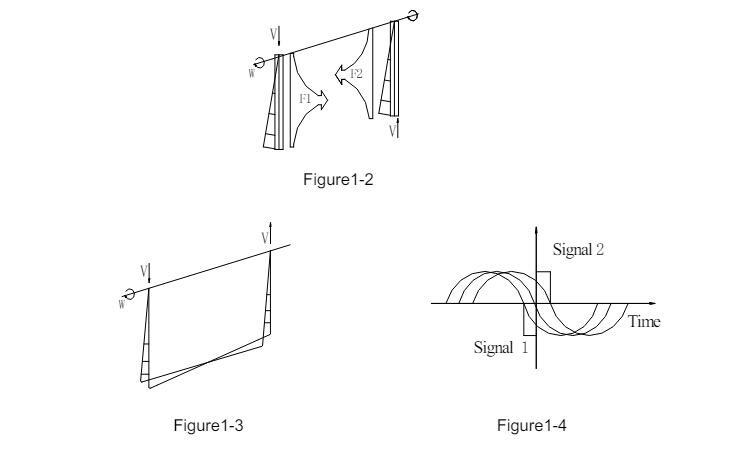

Coriolis flow meter is a flow meter that measures fluid mass based on the Coriolis force principle. It is mainly composed of a flow sensor and a flow transmitter. Sino-Inst U series Coriolis mass flow meter is an advanced high-precision mass flow measurement instrument.

Coriolis Mass Flow Measurement

Coriolis flow meter can directly measure the mass flow rate of fluids. It has low requirements for fluid state and can show excellent performance even in harsh working environments.

Mass flow measurement is the basis of many key elements in all industries. Including most formulations, material balance determinations, and billing and custody transfer operations. Since these are the most critical flow measurements in processing plants, the reliability and accuracy of mass flow detection are very important.

Coriolis Mass Flow Measurement is widely used in a variety of different industrial sectors. For example, life sciences, chemicals, petrochemicals, oil and gas, food, and equally important custody transfer applications.

Coriolis flow meter can measure almost all fluids: detergents, solvents, fuels, crude oil, vegetable oils, animal fats, latex, silicone oil, alcohol, juice, toothpaste, vinegar, ketchup, mayonnaise, gas or liquefied gas. In addition to normal fluids, it can also measure industrial media that are difficult to measure with general fluid measuring instruments, such as non-Newtonian fluids, various slurries, suspensions, etc.

Features of Coriolis Flow Meter

- High-precision measurement ±0.1~0.2%;

- Wide range of applications. 316L stainless steel structure is suitable for a variety of media. The instrument coefficient is not affected by liquid measurement. It can accurately measure gas.

- Multivariable flow. Provides accurate measurement for a range of variables. Including mass flow, volume flow, total flow, density and temperature.

- Adopts MVD multivariable digital technology converter. Transition from analog signal processing to digital signal processing. It can generate stable signals. And then improve the response speed and measurement accuracy.

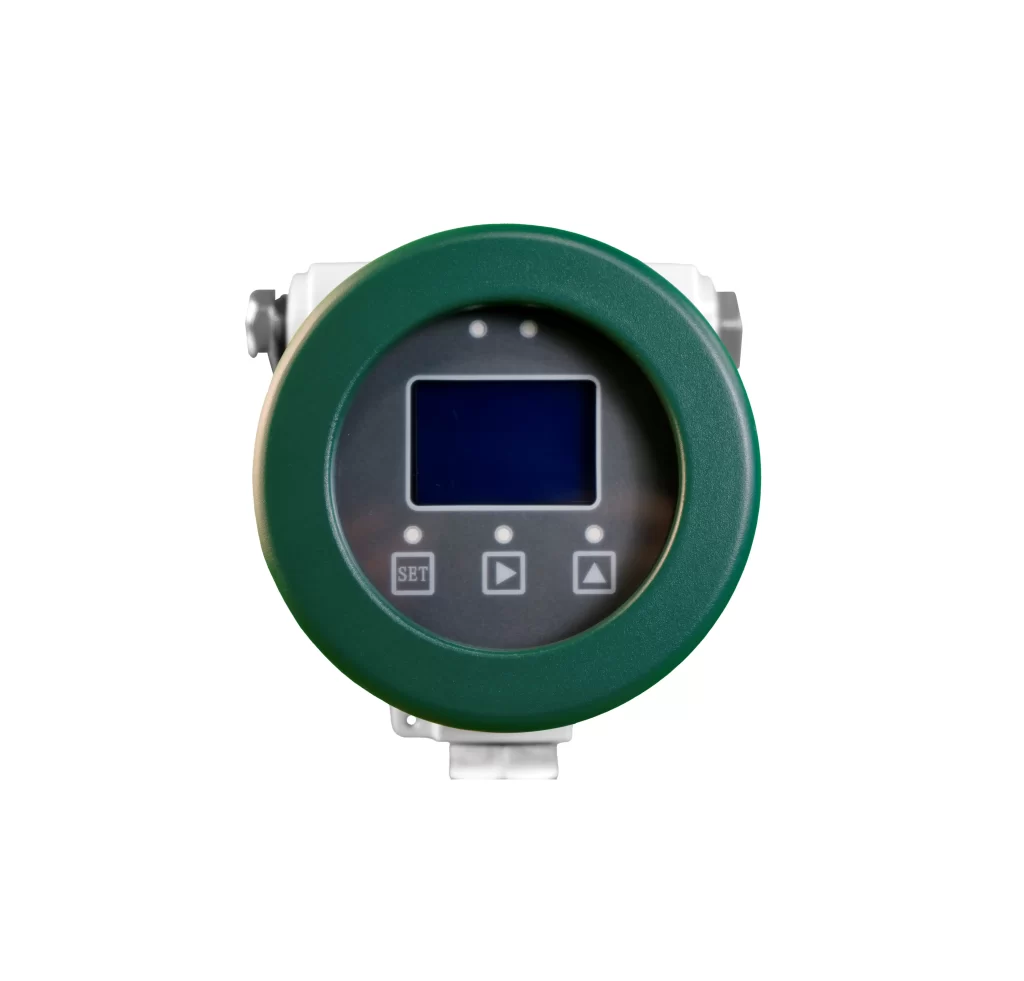

- Easy to use. LCD display, users can touch buttons in Chinese/English. Directly and conveniently perform configuration operations.

- Reliability and repeatability. The wear-free moving parts enable the instrument to maintain reliability and repeatability for a long time. And ensure high-precision flow and density measurement in conventional process control applications.

U Series Coriolis Flow Meter Technical Specifications

Sensor measurement parameters:

| Measuring diameter range: | DN6~DN200 |

| Fluid measurement accuracy: | ±0.1~0.2% |

| Repeatability: | ±0.1~0.25% |

| Density measurement range: | 0.3~3.000g/cm3 , accuracy: ±0.002g/cm3 |

| Working temperature of measured medium: | Standard type: -50~200℃ High temperature type: -50~350℃ Low temperature type: -200~200℃ Measurement accuracy: ±1℃ |

| Measuring tube material: | SS316L |

| Shell material: | SS304 |

| Working pressure: | 0~4.0MPa (high pressure can be customized) |

| Explosion-proof standard: | Exd(ia)IICT6Gb |

Converter measurement parameters:

| Output: | 4-20mA, pulse, RS485 |

| Communication: | MODBUS, HART |

| Power supply: | 220VAC or 24VDC |

| LCD display content: | flow, temperature, density |

| Explosion-proof standard: | Exd(ia)IICT6Gb |

Flow Range and Zero point stability

| Diameter | Flow Range | Zero point stability |

| mm | kg/h | kg/h |

| 0.15% | ||

| 0.10% | ||

| 6 | 0~540~810 | 0.081 |

| 0.066 | ||

| 0.081 | ||

| 8 | 0~960~1440 | 0.144 |

| 0.12 | ||

| 0.144 | ||

| 10 | 0~1500~2250 | 0.225 |

| 0.18 | ||

| 0.225 | ||

| 15 | 0~3000~4500 | 0.45 |

| 0.42 | ||

| 0.45 | ||

| 20 | 0~6000~9000 | 0.9 |

| 0.78 | ||

| 0.9 | ||

| 25 | 0~9600~14400 | 1.44 |

| 1.35 | ||

| 1.44 | ||

| 32 | 0~18000~27000 | 2.7 |

| 2.4 | ||

| 2.7 | ||

| 40 | 0~30000~45000 | 4.5 |

| 3.6 | ||

| 4.5 | ||

| 50 | 0~48000~72000 | 7.2 |

| 6 | ||

| 7.2 | ||

| 80 | 0~120000~180000 | 18 |

| 16 | ||

| 18 | ||

| 100 | 0~192000~300000 | 30 |

| 27 | ||

| 30 | ||

| 150 | 0~360000 | 36 |

| 60 | ||

| 60 | ||

| 200 | 0~900000~1200000 | – |

coriolis flow meter applications

Sino-Inst Coriolis Flow Meter can be used for monitoring in the following areas to meet the needs of batching, mixing processes and commercial metering:

- Chemical industry, such as systems with chemical reactions;

- Petroleum industry, such as water content analysis;

- Oil industry, such as vegetable oil, animal oil and other oils;

- Pharmaceutical industry;

- Coating industry;

- Paper industry;

- Textile printing and dyeing industry;

- Fuel industry, such as oil, heavy oil, coal-water slurry and other fuels, lubricating oil;

- Food industry, such as dissolved gas beverages, health drinks and other fluids;

- Transportation industry, such as the measurement of pipeline transported liquids;

More Featured Flow Measurement Solutions

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

- Use and Maintenance of Coriolis Mass Flowmeters

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

Coriolis Flow Meter is favored for its high accuracy and reliability, and has become an important tool for modern industrial flow measurement. Based on the Coriolis principle, the mass flow meter can accurately measure the mass flow of the fluid without being affected by changes in the physical properties of the medium.

Sino-Inst produces and supplies a full range of mass flow meters. Including U-type, triangle, straight tube structure, etc. High temperature, low temperature, high pressure, and other parameters can be customized.

With our many years of experience in mass flow measurement, we provide you with a more reasonable mass flow measurement solution!

U Series Coriolis Flow Meter-Stable Performance-Better Price

U series Coriolis flow meter - for mass, volume, temperature and density measurement.

Product SKU: U Series Coriolis Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 3699

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)