Mass flow meters are basal for quantifying fluid and gas flow in industrial settings. A mass flow meter is a type of flow meter that accurately measures the mass flow rate of a fluid moving through a pipe. Mass flow rate measures the mass per unit of time, differing from volumetric flow rate – which measures volume per unit of time.

This blog post will help you better understand the options available when selecting a mass flow meter for your particular needs.

Fundamental of Mass Flow Meters and the Principles behind it

Historically, mass flow was estimated by reading volumetric flow meters and then calculating for density, but this method lacked precision. With the advent of modern technology, Mass flow meters are configured to measure mass flow. It indicates the mass rate at which fluid passes through a fixed point within a tube thus quantifying the quantity of fluid moving through the system.

What sets mass flow measurement apart is its resilience against changes in fluid density. Mass flow measurement provides a consistent and reliable metric for the quantity of molecules in the fluid flow, irrespective of pressure or temperature conditions.

Different types of Mass Flow Meters

1. Coriolis Mass Flow Meters: Coupling Fluid Dynamics

Coriolis flow meters are a wonder of modern engineering. Their operation principle relies on the fluid-induced forces that result in the deflection of a vibrating tube. The Coriolis mass flow rate is determined by the phase shift between two sensors on the vibrating tube, where the magnitude of the shift reflects the flow rate.

In addition to mass flow, a Coriolis meter is also capable of independently measuring the fluid density by observing the frequency of the tube’s vibration, where denser fluids vibrate at lower frequencies.

The meter is especially useful for measuring liquids whose viscosity varies with velocity at given temperatures and pressures.

Advantages:

- Highly accurate and reliable.

- Can measure both liquids and gases.

- Measures mass flow directly without needing to compensate for changes in temperature or pressure.

- Can also measure density, which is beneficial in applications where fluid properties are important.

- Provides real-time data for process control.

Applications: Coriolis mass flow meters are used in industries that require precise and accurate measurement of mass flow, such as chemical processing, food and beverage production, oil and gas, and pharmaceuticals.

2. Thermal Mass Flow Meters: Utilizing Heat Transfer

While Coriolis meters rely on the principles of fluid dynamics, thermal mass flow meters take a different approach. They estimate flow rate by introducing heat into the fluid and measuring temperature variation, or by maintaining a probe at a constant temperature and measuring the energy required.

These meters’ temperature sensors detect the temperature differential resulting from the heat transfer to the flowing fluid, and the mass flow rate is determined by either the power applied for heating or the temperature difference between sensors. This makes thermal mass flow meters particularly suitable for gas measurements.

Advantages:

- Ideal for measuring gases in low-flow applications.

- No moving parts, which reduces wear and tear and maintenance costs.

- Accurate and reliable for a wide range of gas types, including air, nitrogen, and natural gas.

- Provides direct mass flow measurement without the need for density compensation.

Applications: Combustion air measurement in large boilers, semiconductor process gas measurement in the chemical and petrochemical industries, research and development applications, gas chromatography, and filter and leak testing.

Common Challenges in Mass Flow Measurement: Limitations of Mass Flow Meters

Mass flow meters can have very high rangeability and high accuracy, but they also have serious limitations. Environmental variables and reading, calculation, and adjustment errors can cause a decrease in efficiency, potential damage to equipment, and, ultimately, a reduction in accuracy.

Potential challenges with mass flow meters include:

- Coriolis mass flow meters require high flow velocities for detection – and this results in high-pressure drops.

- Coriolis meters are expensive when compared with other flow meters. They are also not available for larger-sized pipes.

- Thermal mass flow meters are affected by condensation of moisture (in saturated gases) on the temperature detector. This will cause the thermometer to read low and can lead to corrosion.

- Thermal mass flow meters are affected by coating or material build-up on the sensor. This will inhibit heat transfer and cause the meter to read low.

- Thermal mass flow meters are affected by variations in the specific heat caused by changes in the gas’s composition.

Addressing the Challenges of Mass Flow Measurement

Minimizing the impact of environmental variables plays a vital role in securing accurate mass flow measurements. Temperature compensation in mass flow meters is vital for providing accurate measurements under fluctuating temperature conditions.

To counter this, advanced mass flow meters incorporate real-time temperature data to adjust the flow measurements dynamically, addressing the thermal expansion or contraction of fluids.

External vibrations can also lead to inaccuracies in mass flow readings, especially when they interfere with the sensors’ ability to detect subtle changes in flow.

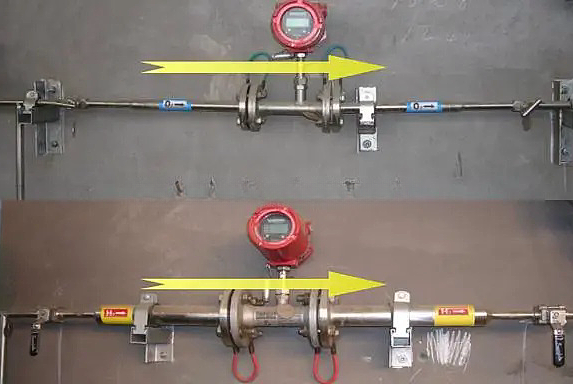

To mitigate this, flow meters often incorporate vibration-damping materials and mounting techniques to isolate the measurement system from any external vibrations.

More Flow Measurement Solutions

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

By understanding the differences in working principles, advantages, and applications of each type of mass flow meter, you can make a more informed decision and select the most appropriate device for your needs. Whether you’re measuring gases, liquids, or even slurries, there is a mass flow meter solution that will provide the accuracy and reliability needed to ensure optimal performance in your process control systems.

Sino-Inst is a hub of the most popular mass flow meter solutions in the market. Our Flowmeter products are in high demand in the Domestic Market and other parts of Southeast Asia, Europe, and America.

If you need to purchase a mass flow meter or have any related technical questions, please feel free to contact our sales engineers!

-1.jpg)