Turbine type flow meter is an important velocity flow meter. It has the advantages of easy maintenance, large flow capacity and relatively low price. It has been widely used to measure the flow of liquids and gases. Including petroleum, organic liquids, natural gas, etc.

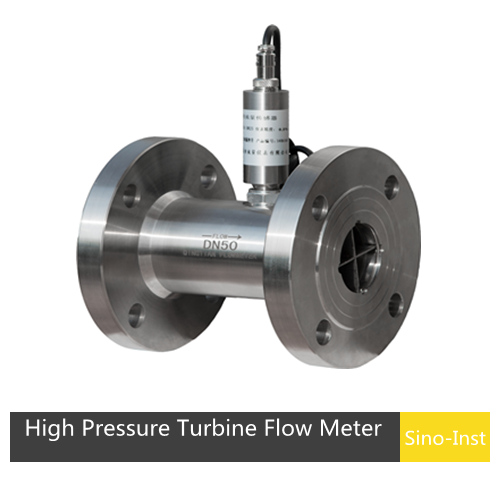

Sino-Inst is one of the manufacturers of Turbine type flow meter, providing economical and efficient turbine flow meters. For example: flange type, sanitary type, insertion type, threaded connection type, etc. And it supports customization of special parameters such as high temperature, low temperature, high pressure, etc.

Featured Turbine Type Flow Meters

Sino-Inst supplies liquid type turbine flow meter and gas type turbine flow meter. Liquid type, sizes range from DN2 to DN300. Gas type, sizes range from DN15 to DN300.

What is a Turbine Type Flow Meter?

The turbine flowmeter is a flow measurement instrument based on the principle of fluid dynamics. Its working principle is to make the turbine rotate by the measured fluid impacting the turbine blades. The speed of the turbine changes with the flow rate. That is, when the flow rate is large, the speed of the turbine is also large; when the flow rate is small, the speed of the turbine is also small.

The rotation of the turbine is converted into a pulse signal of the corresponding frequency by an electromagnetic conversion device. After being amplified by the preamplifier, it is sent to the display instrument for counting and display. According to the number of pulses and the cumulative number of pulses per unit time, the instantaneous flow rate and the cumulative flow rate can be obtained.

Read more about: Turbine Flowmeter Technology

Classification of Turbine Type Flow Meter

According to the different media being measured, we usually classify turbine flowmeters as follows:

Liquid turbine flowmeter

- Ordinary turbine flowmeter: suitable for measuring low viscosity (≤5mPa·s) liquids.

- Corrosion-resistant turbine flowmeter: suitable for measuring corrosive fluids such as dilute sulfuric acid, dilute hydrochloric acid, dilute nitric acid, etc.

- High temperature turbine flowmeter: The temperature of the measured liquid is below 180℃, and the temperature is limited by the temperature resistance of the detection coil.

- Low temperature turbine flowmeter: The measured liquid can be as low as -200℃, and is used for the measurement of liquid oxygen, liquid nitrogen, etc.

- High pressure turbine flowmeter: Special high pressures of 6.3MPa, 16MPa, 25MPa, 32MPa, and 42MPa can be customized.

Gas turbine flowmeter

- Ordinary turbine flowmeter: measures the flow of clean gas.

- Gas turbine flowmeter: suitable for measuring petroleum gas, artificial gas, natural gas and liquefied petroleum gas, etc. Automatic oiler can be used to lubricate and protect bearings, prevent impurities from entering moving parts, and extend service life.

Turbine flow meter VS vortex flow meter

| Items | Turbine flow meters | Vortex flow meters |

| Introduction | A turbine flow meter is a speed meter used to measure the volumetric flow and total volume of low viscosity gases in a closed conduit. It has a wide range of uses in petroleum, chemical, metallurgical, and urban gas pipeline networks. | Vortex flowmeters are mainly used for flow measurement of industrial pipeline media fluids. Such as gases, liquids, vapors and other media. |

| Measuring principle | The turbine flow meter measures the flow rate by rotating a rotor (turbine) in the fluid. When the fluid flows through the flowmeter, the power of the fluid drives the turbine to rotate, and the speed of the turbine is proportional to the flow velocity of the fluid. By measuring the speed of the turbine, the flow rate of the fluid can be obtained. | The vortex flowmeter measures flow based on the vortex phenomenon. When a fluid flows through a non-streamlined obstacle, a periodic vortex is generated behind the obstacle. This phenomenon is called a vortex. The frequency of the vortex is proportional to the flow velocity of the fluid. Therefore, by measuring the vortex frequency, the flow rate of the fluid can be obtained. |

| Measured medium | Non-corrosive low velocity liquid without impurity. Natural gas. | Liquid, gas, steam |

| Pressure | 1.6MPa, 2.5MPa, 6.4MPa, 25MPa, 40MPa | 1.6MPa, 2.5MPa, 6.4MPa, 25MPa, 40MPa |

| Accuracy | Pipe type: Class 1.0 Insertion type: Class 2.5 | 0.5% to 2.0% of reading |

| Output | Pulse, 4-20mA analog output, RS485 (Modbus-RTU protocol), HART | Voltage pulse, 4-20mA output, HART, Modbus, RS485, RS232 options. |

| Installation | Flange connection DN15-DN300 Screw connection: DN2-DN50 Insertion: DN200 or more | DN15~DN300, Flange, clamp flange, thread, clamp connection; DN200~DN2000, insertion type. |

| More Turbine flow meters | More Vortex flow meters |

Turbine type flow meter price

The price of a turbine flow meter is affected by the following factors:

- Measured medium;

- Pipe size

- Pressure size

- temperature;

- Connection method

- Flow range

- Material requirements;

- output signal;

- Whether explosion protection is required.

FAQ

More Flow Measurement Solutions

On the basis of ensuring product quality, Sino-Inst guarantees the best price for customers.

Sino-Inst is a professional turbine flow meter manufacturer and supplier. More than 10 turbine flow meter products are available. About 30% of them are liquid turbine flow meters, and the rest are water, fuel and natural gas turbine flow meters.

Sino-Inst has a mature distribution network covering 50 states in the United States and 30 countries around the world. Turbine flow meter products are most popular in the domestic market, Southeast Asia, Europe and America.

If you need to purchase Turbine Type Flow Meter, or have related customization needs, please feel free to contact our sales engineers!

-1.jpg)