Sulfuric acid is a vital industrial raw material used in the manufacture of fertilizers, pharmaceuticals, pigments, detergents, and batteries. It is widely used in industries such as petroleum purification, metal smelting, and dye production.

In the production and transportation of sulfuric acid, accurate flow measurement is crucial for process control, cost management, and safety. Due to its highly corrosive nature, the selected flowmeter must be resistant to this corrosion.

Electromagnetic Flowmeter: The Preferred Choice for Sulfuric Acid Flow Measurement

When choosing an electromagnetic flowmeter to measure sulfuric acid, the most important considerations are the lining and electrode selection, which directly impact the flowmeter’s service life and measurement accuracy. For highly corrosive media like sulfuric acid, a lining made of polytetrafluoroethylene (PTFE) is essential. Tantalum electrodes are recommended, and platinum electrodes can also be used for higher concentrations.

PTFE is heat-resistant and corrosion-resistant. It is inert to most chemicals and solvents and resistant to strong acids and alkalis. Therefore, it can be used as a lining for measuring concentrated acids, alkalis, highly corrosive solutions, and sanitary media. It is highly lubricating, with the lowest coefficient of friction among solid materials. It does not adhere to any substances. Therefore, PTFE is the perfect lining for sulfuric acid flowmeters.

Concentrated sulfuric acid is highly corrosive, so electrode materials that can withstand this corrosion are essential.

Tantalum electrodes are resistant to nearly all chemical media and are suitable for use with highly corrosive media such as hydrochloric acid and concentrated sulfuric acid. Platinum electrodes are also suitable for various acid, alkali, and salt solutions. Platinum electrodes in sulfuric acid flowmeters can measure high concentrations of sulfuric acid.

In addition, the temperature and conductivity of the medium must also be considered when selecting the electrode material. For high-temperature environments, high-temperature resistant materials such as platinum-iridium alloy or platinum-tungsten alloy can be selected.

High-accuracy Sulfuric Acid Flow and Density Measurement – Mass Flow Meter

Mass flow meters are high-precision measuring instruments widely used in the chemical, pharmaceutical, and petroleum industries. When measuring sulfuric acid, 316 stainless steel is an ideal material for mass flow meters. 316 stainless steel offers excellent corrosion resistance, effectively resisting the corrosive and oxidative effects of sulfuric acid, ensuring measurement accuracy and stability while also extending the life of the device.

Of course, mass flow meters can simultaneously measure and display the mass flow rate, density, and temperature of sulfuric acid.

PTFE Gear Flow Meter: for Low-Flow Sulfuric Acid

PTFE exhibits exceptional resistance to virtually all chemicals, including acids, alkalis, solvents, oxidizing agents, and reducing agents. The PTFE gear flowmeter employs a precision gear transmission mechanism. Due to the inherent low friction and high stability of PTFE material, the gears can more accurately capture fluid flow information during rotation. This enables high-accuracy measurement of sulfuric acid fluid at low flow rates.

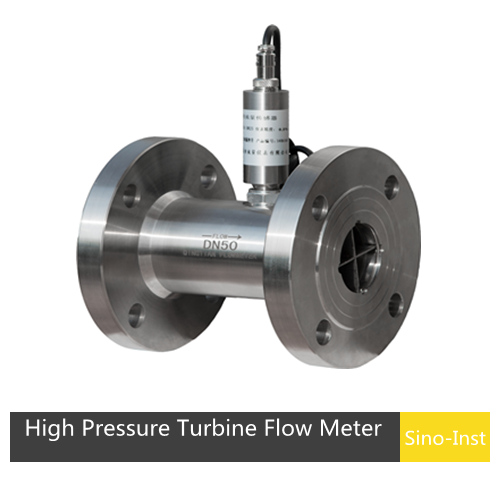

PE Turbine Flowmeter: Highly Cost-Effective

Sulfuric acid can be measured using a turbine flowmeter made of PE. It can measure acid, alkaline, and salt solutions, with a maximum pressure of 0.6 MPa. PE turbine flowmeters are easy to install and offer a high cost-effectiveness, making them a preferred choice when the specific composition of the medium is uncertain. Full pipes are required.

Depending on the pipe diameter and on-site installation requirements, threaded or flanged connections are available. Turbine flow sensors are primarily designed to measure any clean, impurity-free liquid. Filters can be added if necessary.

More Flow Measurement Solutions

In summary, selecting a flowmeter suitable for sulfuric acid requires careful consideration of specific operating conditions and requirements, including accuracy, range, operating pressure, temperature, power supply method, and signal output. In actual applications, comprehensive considerations and selection must be made based on the site environment, media characteristics, and operational experience.

If you require sulfuric acid flow measurement or have questions about flowmeters, please feel free to contact us.

-1.jpg)